The sea water side of the heat exchanger should be

inspected and cleaned on a yearly basis. Remove the

two end caps and flush out any deposits that may

have accumulated in the tubes. Be certain to note the

position of the gaskets when removing the heat

exchanger ends. On some models the gaskets direct

the water flow and when replaced must be positioned

the same way they were when removed.

Captive

Water

Side

The captive water side of the heat exchanger should

be protected from corrosion and scale formation by

filling theenginecooling system with

a50/50

mixture

of antifreeze and water. If not protected, rust and

scale will form on the walls of the engine water jacket.

The rust and scale will combine to form an insulation

layer on the water jacket which will reduce the

efficiency of heat transfer to coolant.This can lead to

overheating and subsequent damage to the engine.

Rusty water or rusty solutions of antifreeze indicate

the formation of rust on the water jacket. If this is the

case, the engine water jacket and heat exchanger

should be cleaned and thoroughly flushed out, as

described

in

the

MAlNTENANCf

section. Use a

chemical cleaner to remove rust and scale deposits,

following the procedure recommended by the sup-

plier.

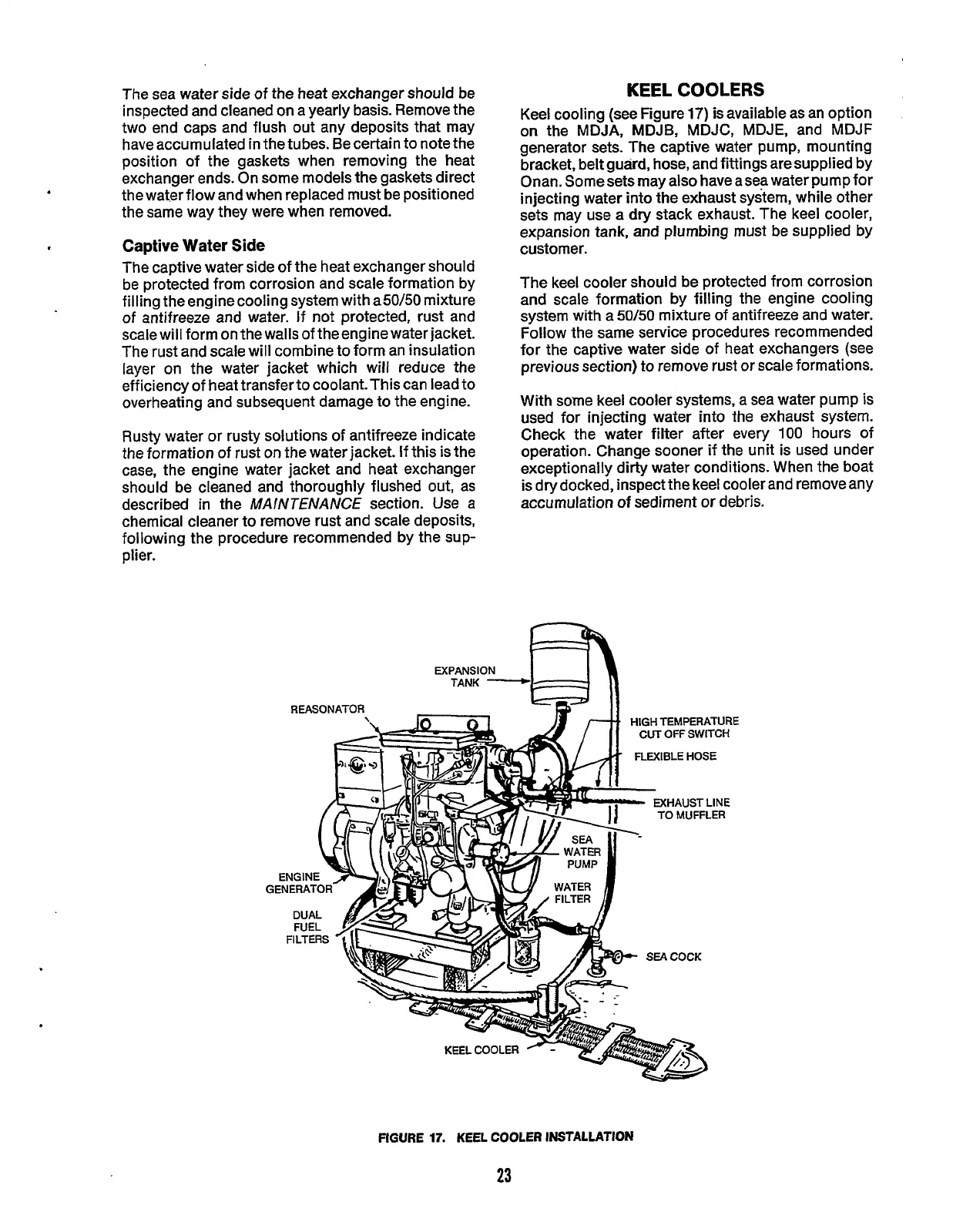

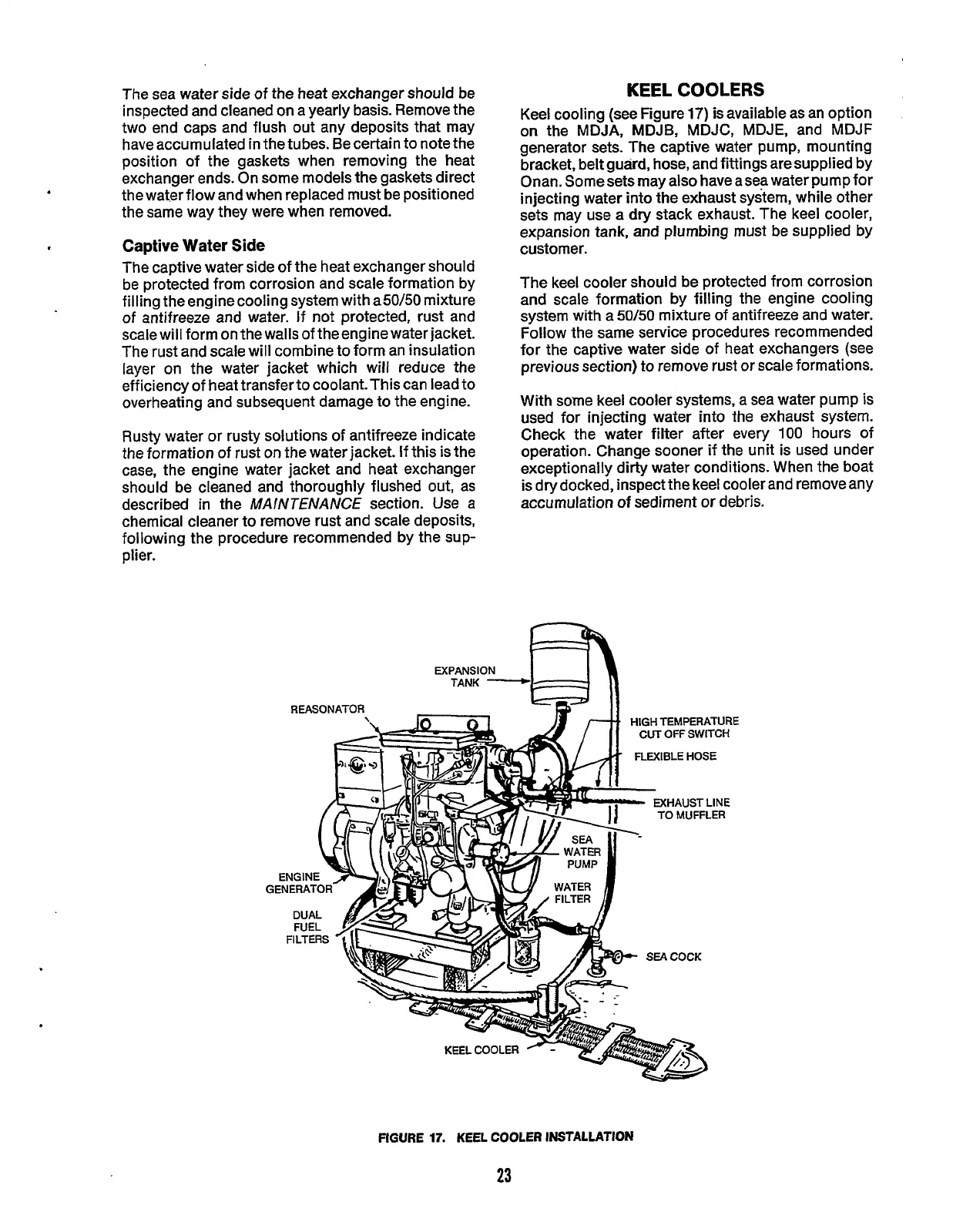

KEEL COOLERS

Keel cooling

(see

Figure

17)

is available as an option

on the

MDJA, MDJB,

MDJC, MDJE, and

MDJF

generator sets. The captive water pump, mounting

bracket, belt guard, hose, and fittings are supplied by

Onan. Somesetsmay also haveasea water pump for

injecting water into the exhaust system, while other

sets may use a

dry

stack exhaust. The keel cooler,

expansion tank, and plumbing must be supplied by

customer.

The keel cooler should be protected from corrosion

and scale formation by filling the engine cooling

system with a

50/50

mixture of antifreeze and water.

Follow the same service procedures recommended

for the captive water side of heat exchangers (see

previous section) to remove rust or scale formations.

With some keel cooler systems, a sea water pump

is

used for injecting water into the exhaust system.

Check the water filter after every

100

hours of

operation. Change sooner if the unit is used under

exceptionally dirty water conditions. When the boat

is dry docked, inspect the keel cooler and remove any

accumulation of sediment or debris.

TANK

-

EXPANSION

FIGURE

17.

KEEL

COOLER INSTALLATION

23

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...