6.

7.

8.

9.

10.

11.

When disassembling engine, mike bearing plate

gasket thickness. Then select proper shim thick-

ness for correct end play.

Shims establish end play. Only one thickness gasket

is

included in kit.

When assembling crankshaft, make sure bearing

thrust washers are in proper position supported

by bearing stop pins. Use cup grease to hold in

place.

When adjusting valve lash, tap rocker arm

so

it is

straight when checking with feeler gauge.

Crank gears are easier

to

remove and install if

heated a slight amount.

Do

not

overheat

or

temper

may

be

lost

and shaft may expand.

See

FUEL

SYSTEM

section for correct engine

timing.

Allow some gear lash, approximately

0.005

inch

(0.13mm) in oil pump.

Donot

installgears tightly

against each other!.

Maintenance

Check the valve clearances at regular intervals (see

OPERATORS

MANUAL).

In addition, clean the com-

bustion chambers and valve seats, as required if

engine loses power or has low compression.

Valve Clearance Adjustments

After engine has reached a stable temperature condi-

tion the valve clearances may be adjusted. It is

recommended that the valve clearance be set with

engine at room temperature (about

75OF

[24O

C]).

Allow at least two hours cooling time after engine

operation.

1.

To

adjust valve clearance on two-cylinder

J

Ser-

ies engine proceed as follows:

A.

Turn flywheel until cylinder which

is

to have

'its valve adjusted is on a compression stroke,

which follows closing

of

intake valve.

B.

Turn flywheel until TC (top center) mark

on

flywheel lines up with timing pointer on gear

cover. Then turn flywheel in

a

clockwise

direction for an additional 10 to 45 degrees.

The timing mark for this position must be

established. In this position, the piston will be

in its Dower stroke with both valves com-

TESTING AND ADJUSTING ENGINES

pletely closed.

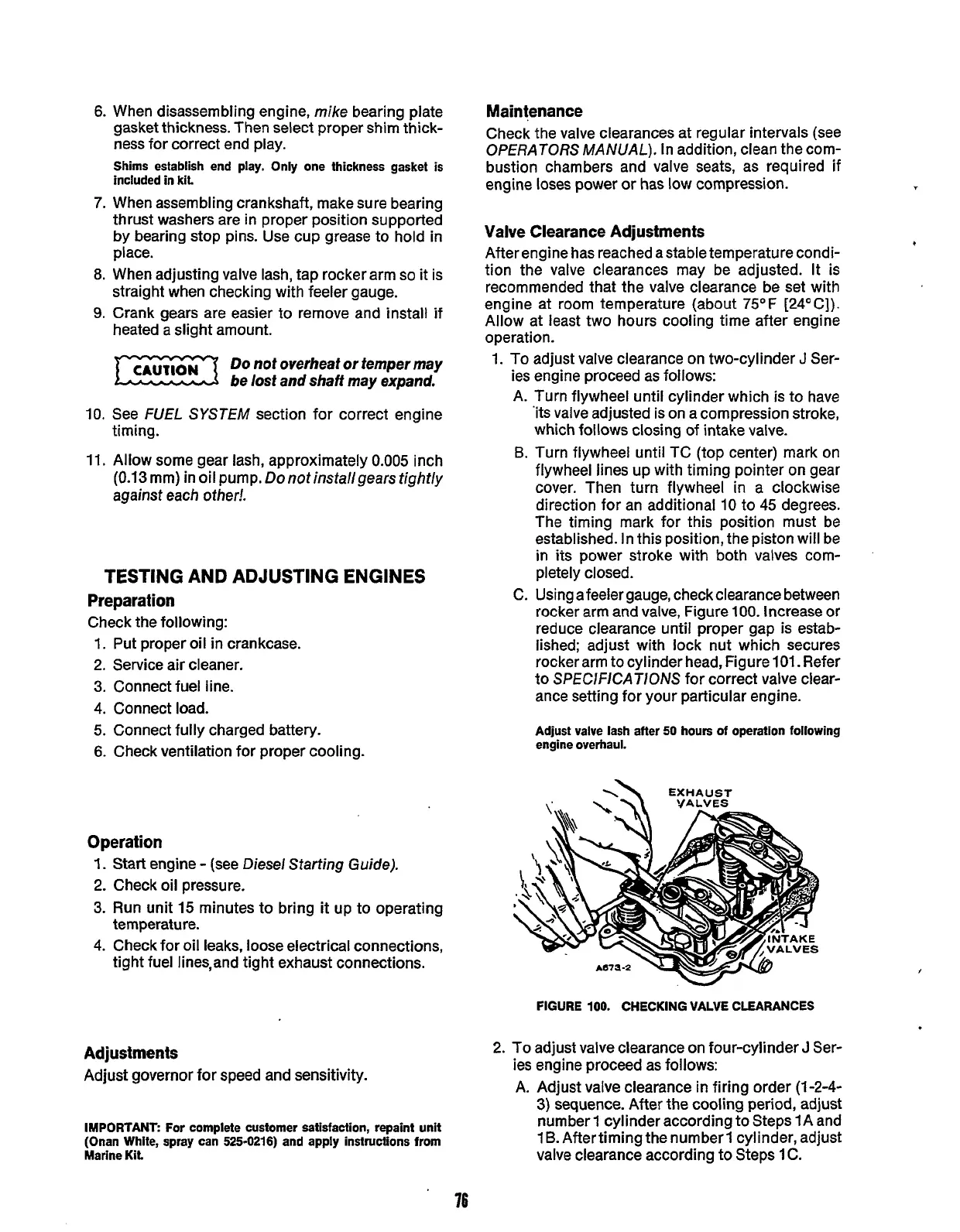

C.

Using a feeler gauge, check clearance between

rocker arm and valve, Figure 100. Increase or

reduce clearance until proper gap is estab-

lished; adjust with lock nut which secures

rocker arm to cylinder head, Figure

101.

Refer

to

SPECIFICATIONS

for correct valve clear-

ance setting for your particular engine.

Preparation

Check the following:

1. Put proper oil in crankcase.

2.

Service air cleaner.

3.

Connect fuel line.

4.

Connect load.

5.

Connect fully charged battery.

6.

Check ventilation for proper cooling.

Operation

1.

Start engine

-

(see Diesel Starting Guide).

2.

Check oil pressure.

3.

Run unit 15 minutes to bring

it

up to operating

temperature.

4.

Check for oil leaks, loose electrical connections,

tight fuel lines,and tight exhaust connections.

Adjust valve lash after

50

hours

of

operation following

engine overhaul.

\\

EXHAUST

A67a-2

'

FIGURE

100. CHECKING VALVE CLEARANCES

Adjust

men

ts

Adjust governor for speed and sensitivity.

2.

To

adjust valve clearance on four-cylinder

J

Ser-

ies engine proceed as follows:

A.

Adjust valve clearance

in

firinn order (1-2-4-

3)

sequence. After the coolinfperiod,'adjust

number

1

cylinder according to Steps 1A and

1

B.

After timing the number

1

cylinder, adjust

valve clearance according to Steps

1

C.

IMPORTANT: For complete customer satisfaction, repaint unit

(Onan White, spray can 5259216) and apply insfructions from

Marine Kit.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...