INTERNAL DISASSEMBLY

If

engine disassembly is necessary, observe the fol-

lowing order (Le. Flywheel, Gear Cover...).

As

disas-

sembly progresses, the order may be changed some-

what as will be self-evident. The engine assembly

procedure

is

the reverse of disassembly. Any special

assembly instructions for a particular group are

included

in

the applicable section. When reassem-

bling, check each section for these special assembly

instructions or procedures.

FLYWHEEL

Remove the blower housing.Theflywhee1 isatapered

fit on the crankshaft. Improvise a puller, using at least

a 7/16 inch (11.113 mm) bar, and drill two 7/16 inch

(1 1.1 13 mm) holes2-7/8 inches

(73.025 mm) between

centers. Loosen the flywheel mounting screw a few

turns. Place bar againstthe flywheelscrew and attach

bar, using two 3/8-16 thread screws in the holes pro-

vided in flywheel. Alternately tighten the screws until

flywheel

is

free.

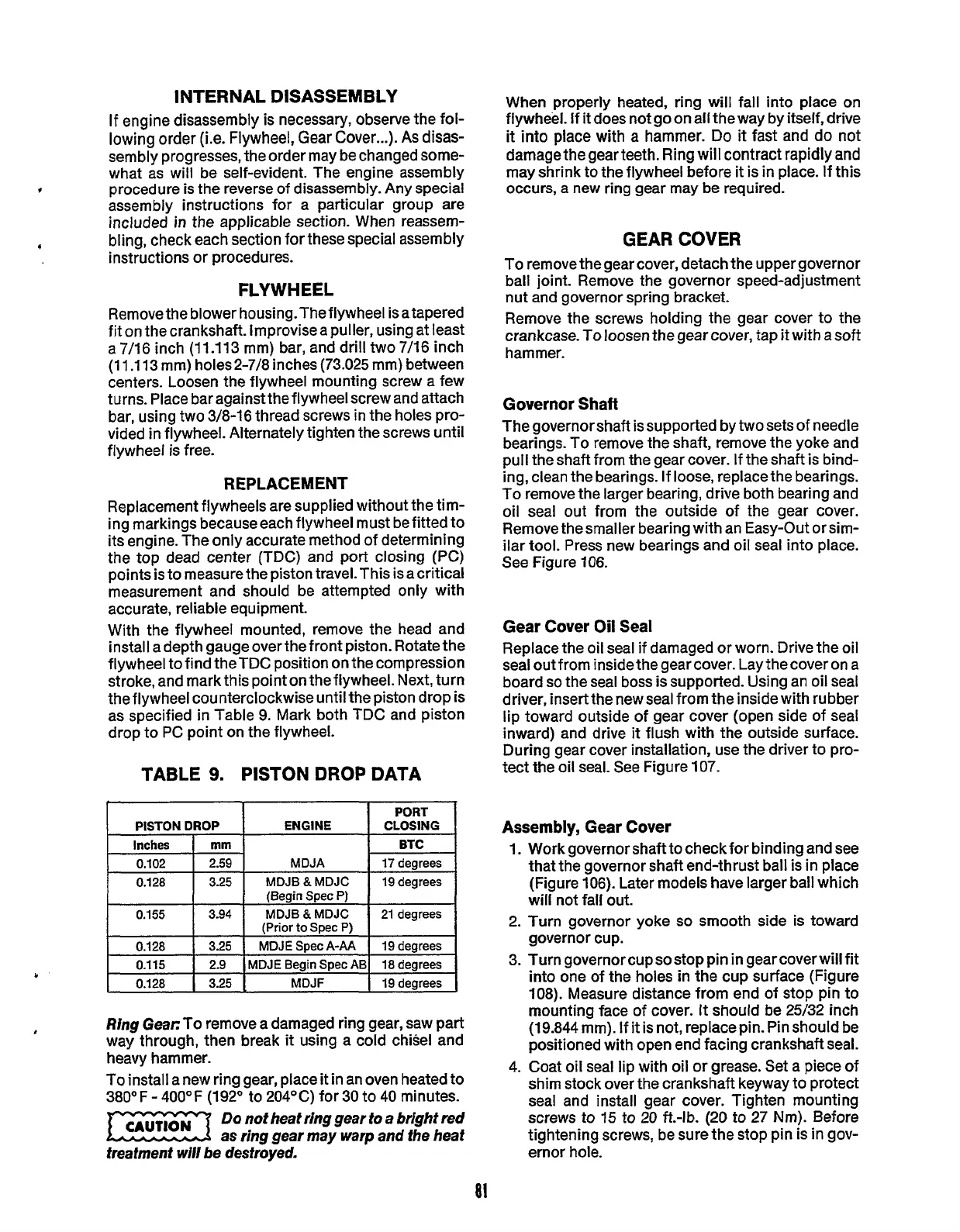

PISTON

DROP

Inches

I

mm

REPLACEMENT

Replacement flywheels are supplied without the tim-

ing markings becauseeach flywheel must befitted to

its engine. The only accurate method of determining

the top dead center (TDC) and port closing

(PC)

points is to measure the piston travel. This is acritical

measurement and should be attempted only with

accurate, reliable equipment.

With the flywheel mounted, remove the head and

install a depth gauge over the front piston. Rotate the

flywheel to find theTDC position on the compression

stroke, and markthis point on theflywheel. Next, turn

the flywheel counterclockwise until the piston drop is

as specified in Table 9. Mark both

TDC and piston

drop to PC point on the flywheel.

PORT

BTC

ENGINE CLOSING

TABLE

9.

PISTON DROP DATA

0.102

I

2.59

I

MDJA

I

17degrees

0.128

I

3.25

I

MDJB&MDJC

I

19degrees

(Begin Spec

P)

(Prior

to

Spec

P)

0.155

0.128

0.115

0.128 3.25

MDJF

19 degrees

Ring Gear:

To

remove a damaged ring gear, saw part

way through, then break

it

using a cold chisel and

heavy hammer.

To install a new ring gear, place

it

in an oven heated to

380°

F

-

400OF (192O to 204OC) for

30

to

40

minutes.

Do

not heat ring gear to a bright red

as ring gear may warp and the beat

treatment wiN be destroyed.

When properly heated, ring will fall into place

on

flywheel. If

it

does not go on all theway by itself, drive

it

into

place with

a

hammer.

Do

it

fast and do not

damagethe gear teeth. Ring will contract rapidly and

may shrink to the flywheel before

it

is

in

place. If this

occurs,

a

new

ring gear may be required.

GEAR

COVER

To remove the gear cover, detach the upper governor

ball joint. Remove the governor speed-adjustment

nut and governor spring bracket.

Remove the screws holding the gear cover to the

crankcase. To loosen the gear cover, tap

it

with asoft

hammer.

Governor Shaft

The governor shaft is supported by

two

sets of needle

bearings. To remove the shaft, remove the yoke and

pull the shaft from the gear cover. If the shaft is bind-

ing, clean the bearings. If loose, replacethe bearings.

To remove

the

larger bearing, drive both bearing and

oil seal out from the outside of the gear cover.

Remove thesmaller bearing with an Easy-Out orsim-

ilar tool. Press new bearings and oil seal into place.

See Figure

106.

Gear

Cover

Oil

Seal

Replace the oil seal if damaged or worn. Drive the oil

seal out from inside

the

gear cover. Lay the cover on a

board

so

the seal boss is supported. Using an oil seal

driver, insertthe new seal from

the

inside with rubber

lip toward outside of gear cover (open side of seal

inward) and drive

it

flush with the outside surface.

During gear cover installation, use the driver to pro-

tect the oil seal. See Figure

107.

Assembly, Gear Cover

1.

2.

3.

4.

Work governor shaft to check for binding and see

that the governor shaft end-thrust ball is in place

(Figure 106). Later models have larger ball which

will not fall out.

Turn governor yoke

so

smooth side is toward

governor cup.

Turn governorcupsostop pin

in

gearcoverwill fit

into one of the holes in

the

cup surface (Figure

108). Measure distance from end of stop pin to

mounting face of cover.

It

should be 25/32 inch

(19.844 mm).

If

it

is not, replace

pin.

Pin should be

positioned with open end facing crankshaft seal.

Coat oil seal lip with oil or grease. Set a piece of

shim stock over the crankshaft keyway to protect

seal and install gear cover. Tighten mounting

screws to

15

to

20

ft.-lb.

(20

to 27

Nm).

Before

tightening screws, be sure

the

stop pin is in gov-

ernor hole.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...