DELIVERY VALVE

FU

NCTl

ON

The delivery valve maintains 300 to

600

psi

(2070

to

4140 kPa) line pressure

in

the injector lines with the

engine running, Figure 31. This pressure increasesto

about 1900 psi (13110 kPa) on each stroke of the

injection pump plunger. The trapped fuel is held

in

the lines at all times, even though the pressure bleeds

off during shutdown periods. When the lines are full of

fuel, onlyacoupleturnsof thecrankshaft are required

to build up enough line pressure for firing the

injectors.

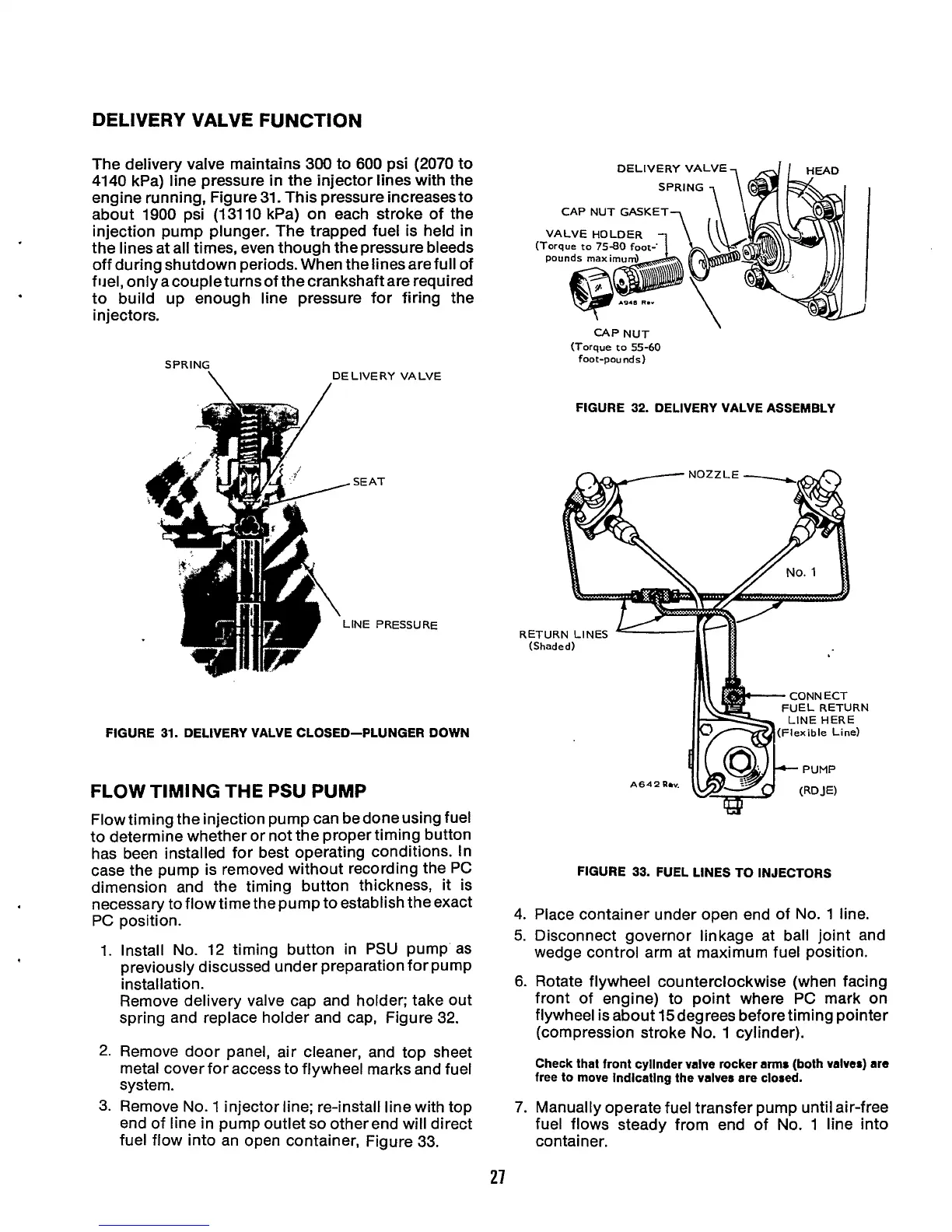

SPRING

DELIVERY VALVE

\

/

.SEAT

.IN€ PRESSURE

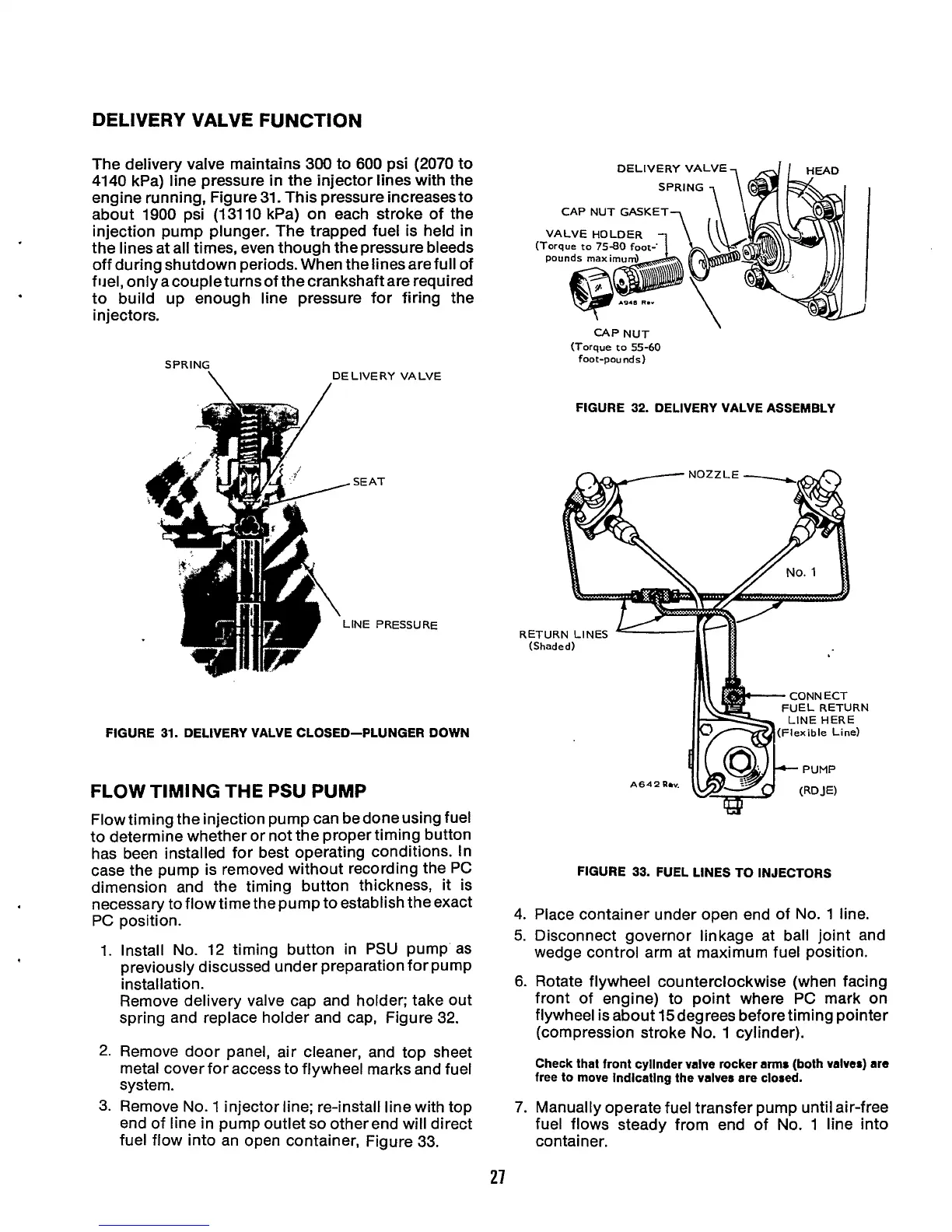

DELIVERY VALVE

CAP NUT GASKET

CAP

NUT

\

(Torque

to

55-60

foot-pounds)

FIGURE

32.

DELIVERY VALVE ASSEMBLY

RETURN LINES

UEL RETURN

LINE HERE

(Flexible

Line)

FIGURE

31.

DELIVERY VALVE CLOSED-PLUNGER DOWN

FLOW

TIMING

THE

PSU

PUMP

Flow timing the injection pump can bedone using fuel

to determine whether or not the proper timing button

has been installed for best operating conditions. In

case the pump is removed without recording the PC

dimension and the timing button thickness, it is

necessary to flow time the pump to establish the exact

PC position.

1.

Install

No.

12 timing button in PSU pump as

previously discussed under preparation for pump

installation.

Remove delivery valve cap and holder; take out

spring and replace holder and cap, Figure

32.

2. Remove door panel, air cleaner, and top sheet

metal cover for access to flywheel marks and fuel

system.

3.

Remove

No.

1

injector line; re-install line with top

end of line in pump outlet

so

other end will direct

fuel flow into an open container, Figure 33.

FIGURE

33.

FUEL LINES TO INJECTORS

4.

Place container under open end of

No.

1 line.

5.

Disconnect governor linkage at ball joint and

wedge control arm at maximum fuel position.

6.

Rotate flywheel counterclockwise (when facing

front of engine) to point where PC mark on

flywheel is about 15 degrees before timing pointer

(compression stroke

No.

1

cylinder).

Check that front cyllnder valve rocker arms (both valves) are

free

to move lndlcatlng the valves are closed.

7.

Manually operate fuel transfer pump until air-free

fuel flows steady from end of

No.

1 line into

container.

27

Loading...

Loading...