SERVICE

AND

MAINTENANCE

PR

E-STARTI

N

G

Preparations for the initial and each additional star-

ting operation should include careful checks of the

oil, fuel, cooling, and electrical systems. The cylinder

air housing door should be closed with all airshrouds

in

place.

Before engine is put in operation, check all com-

ponents for mechanical security. If an abnormal

condition, defective part, or operating difficulty is

detected, repair or service as required. The engine

should be kept free of dust,

dirt,

and spilledoil or fuel.

Be sure proper operating procedure is followed.

Crankcase

Oil:

Use an oil with the API designation

CD/SD or CD/SE. However, to reduce oil consump-

tion to a normal level in theshortest time possible on a

new or rebuilt engine, use CC oil for the first fill only

(50

hours). Then use the recommended oil only.

Select the correct SAE grade oil by referring to the

following:

Above

32"

F

(0"

C)

.......................

SAE

30

0"

F

to

32" F

(-18" C to 0°C)

...

SAE 1OW or

5W-30

Below

0"

F

(-18"

C)

..................

SAE

5W-30

Multigrade oils are recommended for temperatures of

32"

F

(0"

C) and below, but they are not recommend-

ed for temperatures above

32"

F

(0"

C). When adding

oil between oil changes,

it

is preferable to use the

same brand as various brands of oil may not be

compatible when mixed together.

Never remove

011

level Indicator cap with the

engine running, because oil will blow out of

the tube causing possible injury.

Recommended Fuel:

Although number

2

diesel fuel

gives the best economy for most operating con-

ditions, number

1

diesel fuel can be used:

1.

When ambient temperatures are below

32°F

2.

During long periods of light engine load;

or,

3.

If preferred by user.

(0"

C);

Use low sulfur content fuel having a pour point (ability

to filter) of at least 10" below the lowest expected

temperature. Keep the fuel clean and protected from

adverse weather. Leave some room for expansion

when filling the fuel tank.

Due to the precise tolerances of diesel injec-

tion systems, it is extremely important the fuel

be kept clean. Dirt in the system can cause severe damage to both

the injection pump and the injection nozzles.

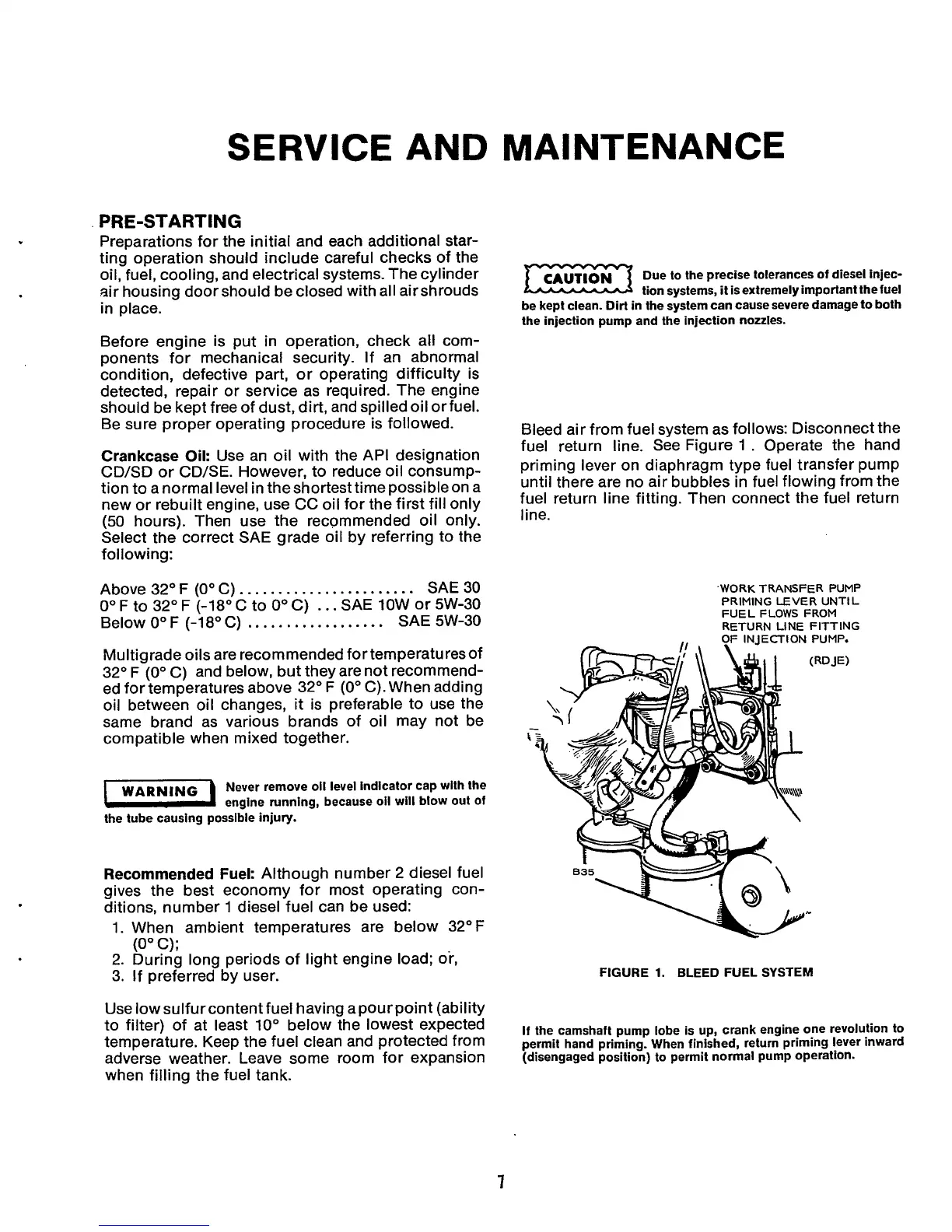

Bleed air from fuel system as follows: Disconnect the

fuel return line. See Figure 1

.

Operate the hand

priming lever on diaphragm type fuel transfer pump

until there are no air bubbles in fuel flowing from the

fuel return line fitting. Then connect the fuel return

line.

'WORK

TRANSFER PUMP

PRIMING LEVER UNTIL

FUEL

FLOWS FROM

RETURN

LINE

FITTING

OF

INlECTlON PUMP.

FIGURE

1.

BLEED FUEL SYSTEM

If

the camshaft pump lobe is up, crank engine one revolution to

permit hand priming. When finished, return priming lever inward

(disengaged position) to permit normal pump operation.

7

Loading...

Loading...