6.

When disassembling engine,

mike

bearing plate

gasket thickness. Then select proper shim

thickness for correct end play.

Shims establish end play. Only one thickness gasket is

included in kit.

7.

When assembling crankshaft, make sure bearing

thrust washers are in proper position supported

by bearing stop pins. Use cup grease to hold in

-

place.

8.

When adjusting valve lash, tap rocker arm

so

it is

9.

Crank gears are easier to remove and install if

straight when checking with feeler gauge.

heated a slight amount.

Do

not overheat or temper may be lost

and shaft may expand.

10.

See

FUEL SYSTEM

section for correct engine

time for specific model.

11.

Allow some gear lash (approximately 0.005-inch)

in oil pump.

Do

not install gears tightly against

each other!

TESTING AND ADJUSTING ENGINES

Preparation

Check the following:

1.

Put

proper oil in crankcase.

2.

Service air cleaner.

3.

Connect fuel line.

4. Connect load.

5.

Connect fully charged battery.

6.

Check ventilation for proper cooling.

OPERATION

1.

Start engine.

2.

Check o.il pressure.

3.

Run unit

15

minutes to bring up to operating

temperature.

'

4. Check for oil leaks, loose electrical connections,

tight fuel lines and tight exhaust connections.

ADJUSTMENTS

Adjust governor for speed and sensitivity.

IMPORTANT:

For complete customer satisfaction, repaint unit

(Onan Green, spray can 525-0137, or Onan White, spray can 525-

0216) and apply instructions from Kit

98-11OOC

or Marine Kit

98-

1807.

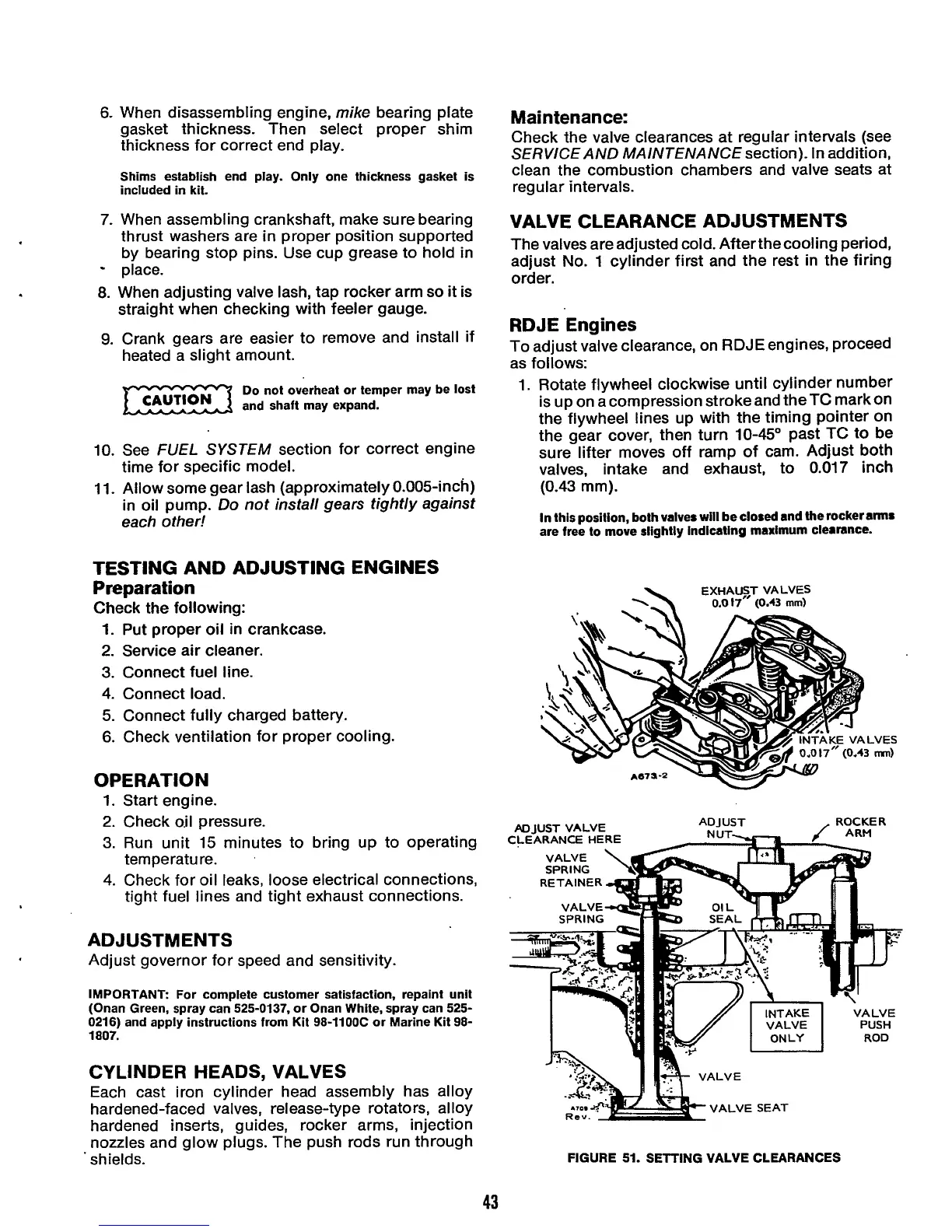

CYLINDER HEADS, VALVES

Each cast iron cylinder head assembly has alloy

hard en ed-f aced valves,

re1

ease-ty pe rotato rs

,

al

I

oy

hardened inserts, guides, rocker arms, injection

nozzles and glow plugs. The push rods run through

'

shields.

Maintenance:

Check the valve clearances at regular intervals (see

SERVICE AND MAINTENANCE

section).

In

addition,

clean the combustion chambers and valve seats at

regular intervals.

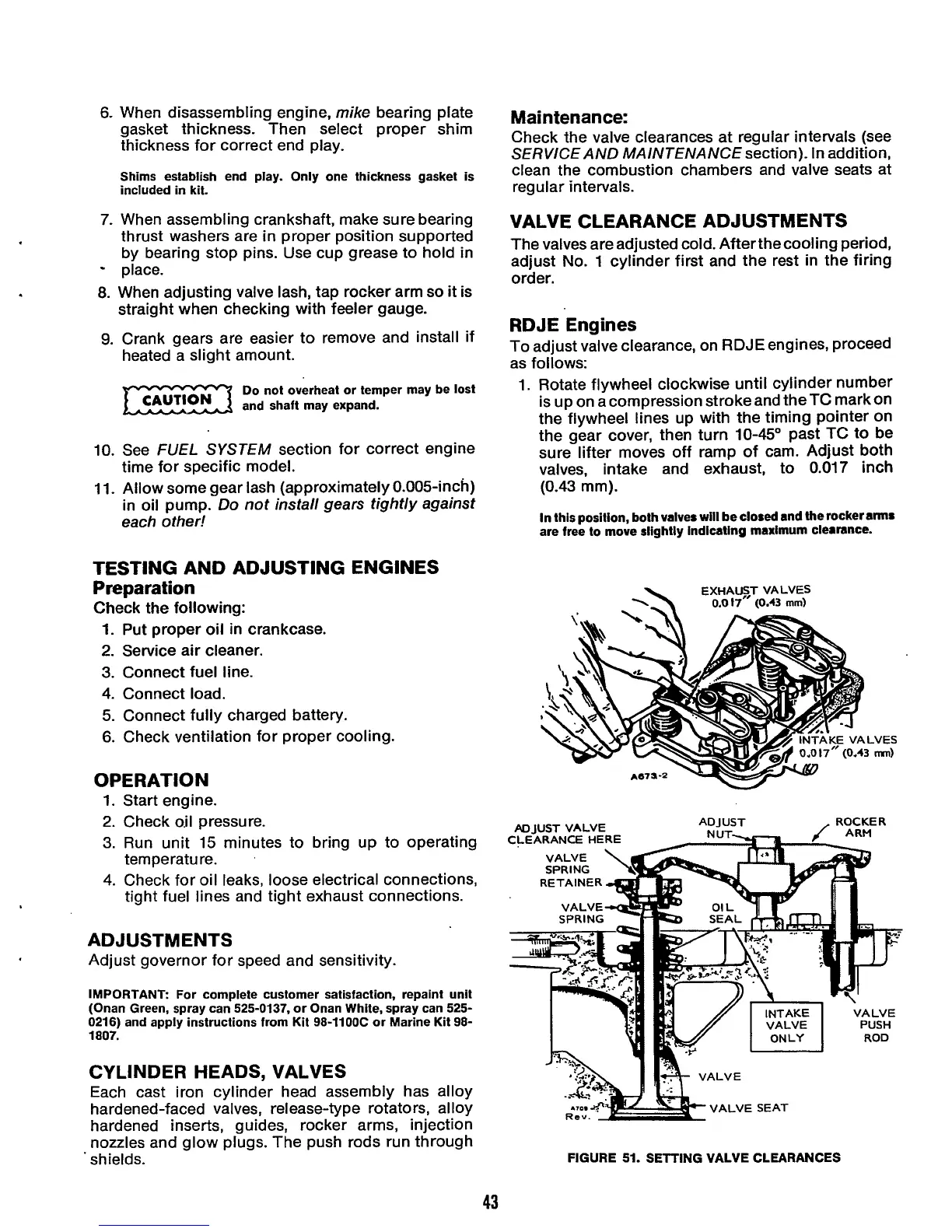

VALVE CLEARANCE ADJUSTMENTS

The valves are adjusted cold. Afterthecooling period,

adjust

No.

1

cylinder first and the rest in the firing

order.

RDJE Engines

To

adjust valve clearance, on

RDJE

engines, proceed

as follows:

1.

Rotate flywheel clockwise until cylinder number

is up on acompression strokeand theTC markon

the flywheel lines up with the timing pointer on

the gear cover, then turn

10-45"

past TC to be

sure lifter moves off ramp of cam. Adjust both

valves, intake and exhaust, to

0.017

inch

(0.43

mm).

In this position, both valves will be closed and the rocker

arms

are free to move slightly indicating maximum clearance.

EXHAUST

VALVES

I\

0.017"

(0.43

rnm)

AOJUST

VALVE

CLEARANCE

HE

VALVE

SEAT

FIGURE

51.

SETTING VALVE CLEARANCES

43

Loading...

Loading...