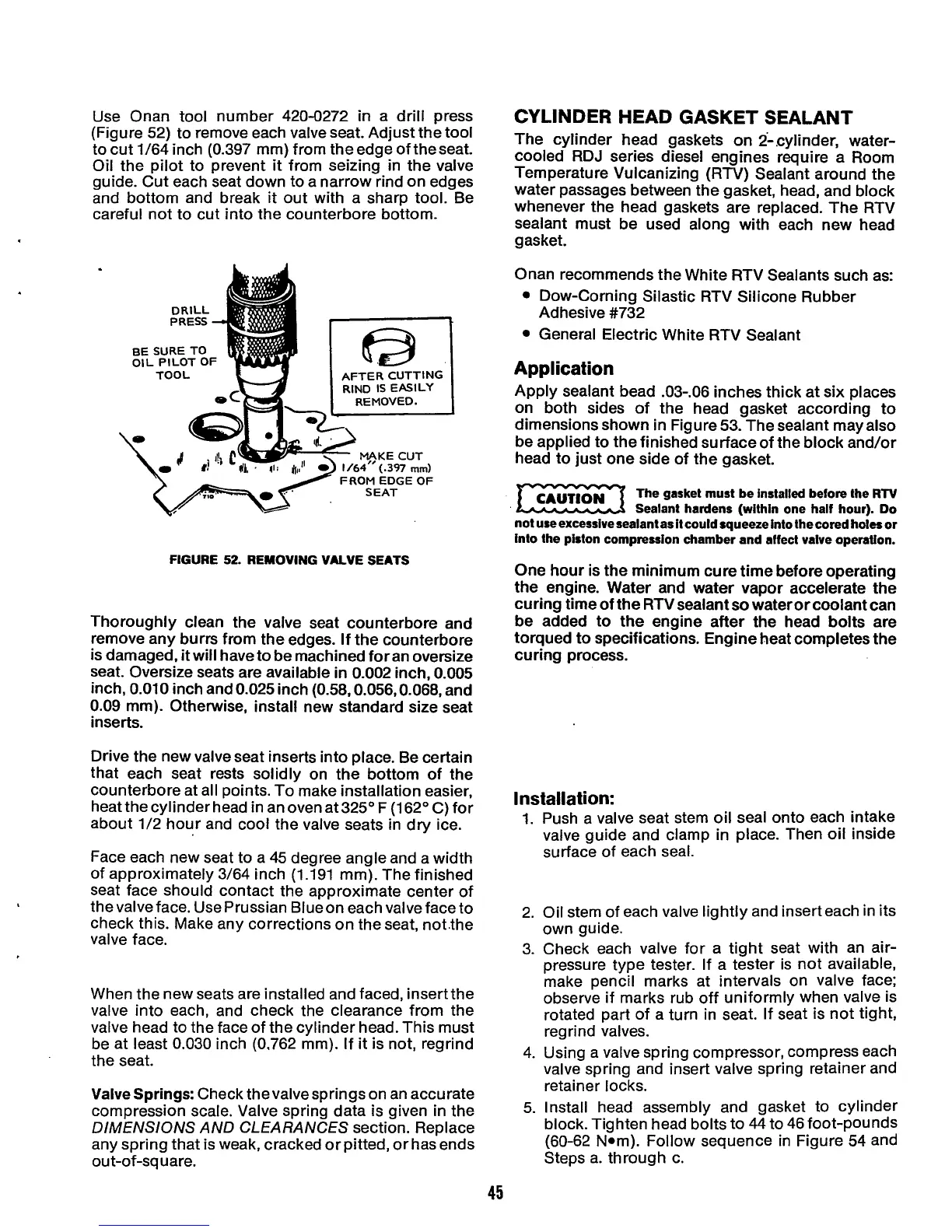

Use Onan tool number 420-0272

in

a drill press

(Figure 52) to remove each valve seat. Adjust the tool

to cut 1/64 inch (0.397 mm) from the edge of theseat.

Oil the pilot to prevent

it

from seizing in the valve

guide. Cut each seat down to a narrow rind on edges

and bottom and break

it

out with a sharp tool. Be

careful not to cut into the counterbore bottom.

DRILL

PRESS

BE

SURE

TO

OIL PILOT OF

TOOL

AFTER CUTTING

RIND

IS

EASILY

REMOVED.

I

MAKE CUT

FROM

EDGE

OF

FIGURE

52.

REMOVING VALVE SEATS

Thoroughly clean the valve seat counterbore and

remove any burrs from the edges. If the counterbore

is damaged,

it

will have to be machined for an oversize

seat. Oversize seats are available

in

0.002

inch,

0.005

inch,

0.010

inch and 0.025 inch

(0.58,0.056,0.068,

and

0.09

mm). Otherwise, install new standard size seat

inserts.

Drive the new valve seat inserts into place. Be certain

that each seat rests solidly on the bottom of the

counterbore at all points. To make installation easier,

heatthecylinderhead in anovenat325'F (162"C)for

about 1/2 hour and cool the valve seats in dry ice.

Face each new seat to a 45 degree angle and a width

of approximately 3/64 inch (1.191 mm). The finished

seat face should contact the approximate center of

thevalve face. Use Prussian Blueon each valve face to

check this. Make any corrections on the seat, notlhe

valve face.

When the new seats are installed and faced, insertthe

valve into each, and check the clearance from the

valve head to the face of the cylinder head. This must

be at least

0.030

inch (0.762 mm).

If

it is not, regrind

the seat.

Valve

Springs:

Check thevalvesprings on an accurate

compression scale. Valve spring data is given in the

DIMENSIONS AND CLEARANCES

section. Replace

any spring that is weak, cracked orpitted, orhas ends

ou t-of-square.

CYLINDER HEAD GASKET SEALANT

The cylinder head gaskets on 2-,cylinder, water-

cooled RDJ series diesel engines require a Room

Temperature Vulcanizing

(RTV)

Sealant around the

water passages between the gasket, head, and block

whenever the head gaskets are replaced. The RTV

sealant must be used along with each new head

gasket.

Onan recommends the White RTV Sealants such as:

Dow-Corning Silastic RTV Silicone Rubber

General Electric White RTV Sealant

Adhesive #732

Application

Apply sealant bead .03-.06 inches thick at six places

on both sides of the head gasket according to

dimensions shown in Figure 53. The sealant may also

be applied to the finished surfaceof the block and/or

head to just one side of the gasket.

The gasket must be installed before the

RTV

KZx

Sealant hardens (within one half hour).

Do

not useexcessivesealantas it couldsqueezeinto thecored holesor

into the piston compression chamber and affect valve operation.

One

hour

is the minimum cure time before operating

the engine. Water and water vapor accelerate the

curing time of the RTV sealant

so

wateror coolant can

be added to the engine after the head bolts are

torqued to specifications. Engine heat completes the

curing process.

Installation:

1. Push a valve seat stem oil seal onto each intake

valve guide and clamp in place. Then oil inside

surface of each seal.

2. Oil stem

of

each valve lightly and insert each in its

own guide.

3.

Check each valve for a tight seat with an air-

pressure type tester.

If

a tester is not available,

make pencil marks at intervals on valve face;

observe if marks rub off uniformly when valve is

rotated part of a turn in seat. If seat is not tight,

regrind valves.

4. Using a valve spring compressor, compress each

valve spring and insert valve spring retainer and

retainer locks.

5.

Install head assembly and gasket to cylinder

block. Tighten head bolts to 44 to 46 foot-pounds

(60-62 Nom). Follow sequence in Figure 54 and

Steps a. through c.

45

Loading...

Loading...