Thoroughly clean the valve seat counterbore and

remove any burrs from the edges. If the counterbore

is

damaged,

it

will have to be machined foran oversize

seat. Oversize seats are available

in

0.002 inch,

0.005

inch,

0.010

inch and 0.025 inch (0.58,0.056,0.068. and

0.09

mm). Otherwise, install new standard size seat

inserts.

Drive the new valve seat inserts into place. Be certain

that each seat rests solidly on the bottom of the

counterbore at all points. To make installation easier,

heat the cylinder head in an oven at 325" F (162" C) for

about 1/2 hour and cool the valve seats in dry ice.

Face each new seat to a 45 degree angle and a width

of approximately 3/64 inch

(1.191

mm). The finished

seat face should contact the approximate center of

the valve face. Use Prussian

BI

ue on each valve face to

check this. Make any corrections on the seat, not the

valve face.

<

.

When the new seats are installed and faced, insert the

valve into each, and check the clearance from the

valve head to the face of the cylinder head. This must

be at least

0.030

inch (0.762 mm). If it is not, regrind

the seat.

Valve

Springs:

Check thevalve springson an accurate

compression scale. Valve spring data is given

in

the

DIMENSIONS AND CLEARANCES

section. Replace

any spring that is weak, cracked or pitted, or has ends

out-of-square.

VALVE AND HEAD ASSEMBLY

Installation

1.

2.

3.

4.

5.

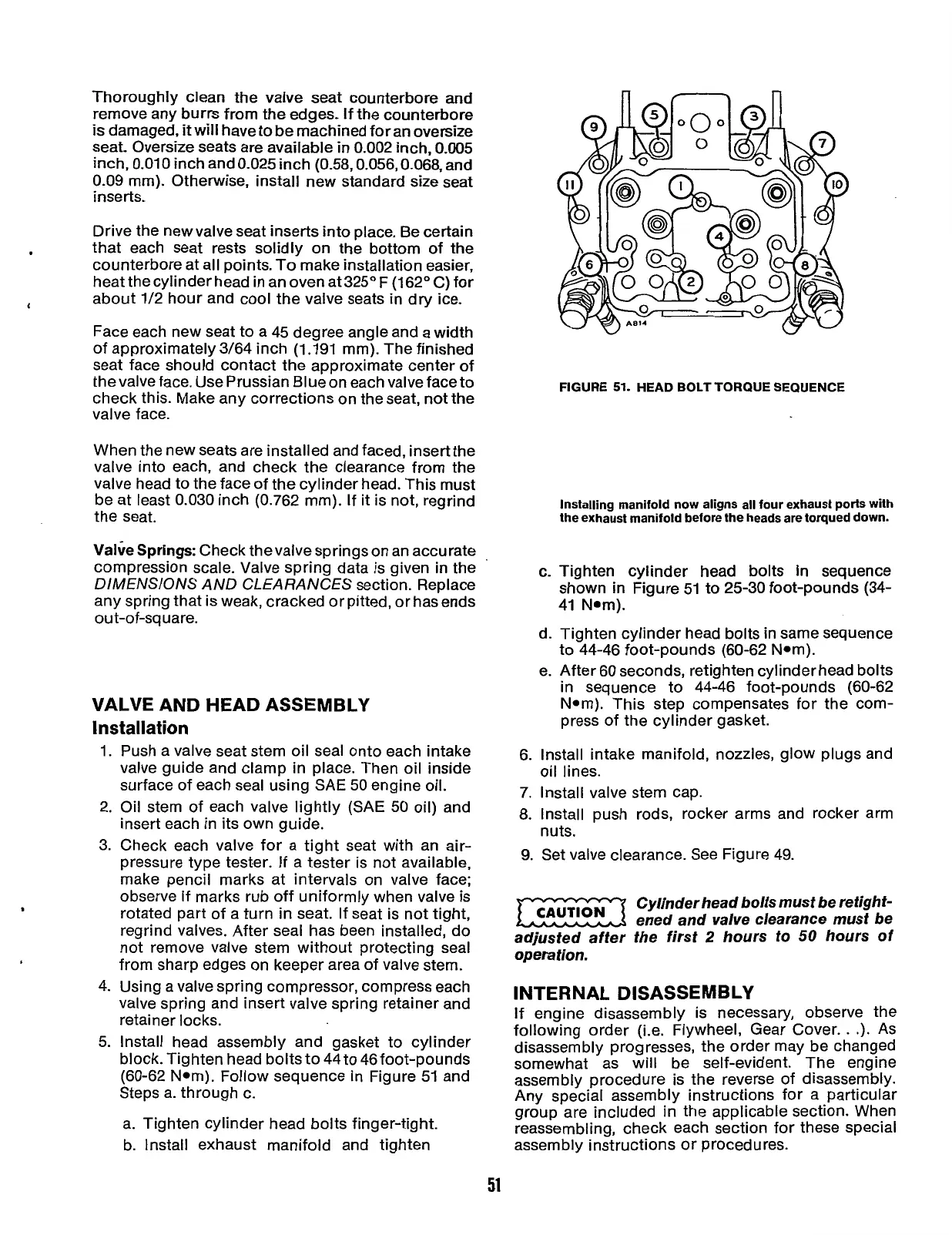

FIGURE

51.

HEAD BOLT TORQUE SEQUENCE

Installing manifold now aligns all four exhaust ports with

the exhaust manifold before the heads are torqued down.

c.

Tighten cylinder head bolts

in

sequence

shown

in

Figure

51

to 25-30 foot-pounds (34-

41

Nom).

d. Tighten cylinder head bolts in same sequence

to 44-46 foot-pounds (60-62 Nom).

e. After 60 seconds, retighten cylinder head bolts

in

sequence to 44-46 foot-pounds (60-62

Nom). This step compensates for the com-

press of the cylinder gasket.

Push a valve seat stem oil seal onto each intake

valve guide and clamp in place. Then oil inside

surface of each seal using SAE

50

engine oil.

Oil stem of each valve lightly (SAE

50

oil) and

insert each in its own guide.

6. Install intake manifold, nozzles, glow plugs and

7. Install valve stem cap.

8. Install push rods, rocker arms and rocker arm

oil lines.

nuts.

9.

Set valve clearance. See Figure

49.

Check each valve for a tight seat with an air-

Dressure tvDe tester. If a tester is not available,

make peniil marks at intervals on valve face;

observe if marks rub off uniformly when valve is

Cylinder head bolfs

must

be refighf-

rotated part of a turn

in

seat. If seat is not tight,

ened and valve clearance

musf

be

regrind valves. After seal has been installed, do

affer

the hours

50

hours

of

not remove valve stem without protecting seal

from sharp edges on keeper area of valve stem.

CAUT'oN

Using a valve spring compressor, compress each

valve spring and insert valve spring retainer and

retainer locks.

Install head assembly and gasket to cylinder

block. Tighten head bolts to 44 to 46foot-pounds

(60-62 Nom). Follow sequence in Figure

51

and

Steps a. through

c.

a. Tighten cylinder head bolts finger-tight.

b. Install exhaust manifold and tighten

INTERNAL DISASSEMBLY

If engine disassembly is necessary, observe the

following order (i.e. Flywheel, Gear Cover..

.).

As

disassembly progresses, the order may be changed

somewhat as will be self-evident. The engine

assembly procedure is the reverse of disassembly.

Any special assembly instructions for a particular

group are included

in

the applicable section. When

reassembling, check each section for these special

assembly instructions or procedures.

51

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...