OPTEK DPL-24

6

PRINCIPLES OF OPERATION

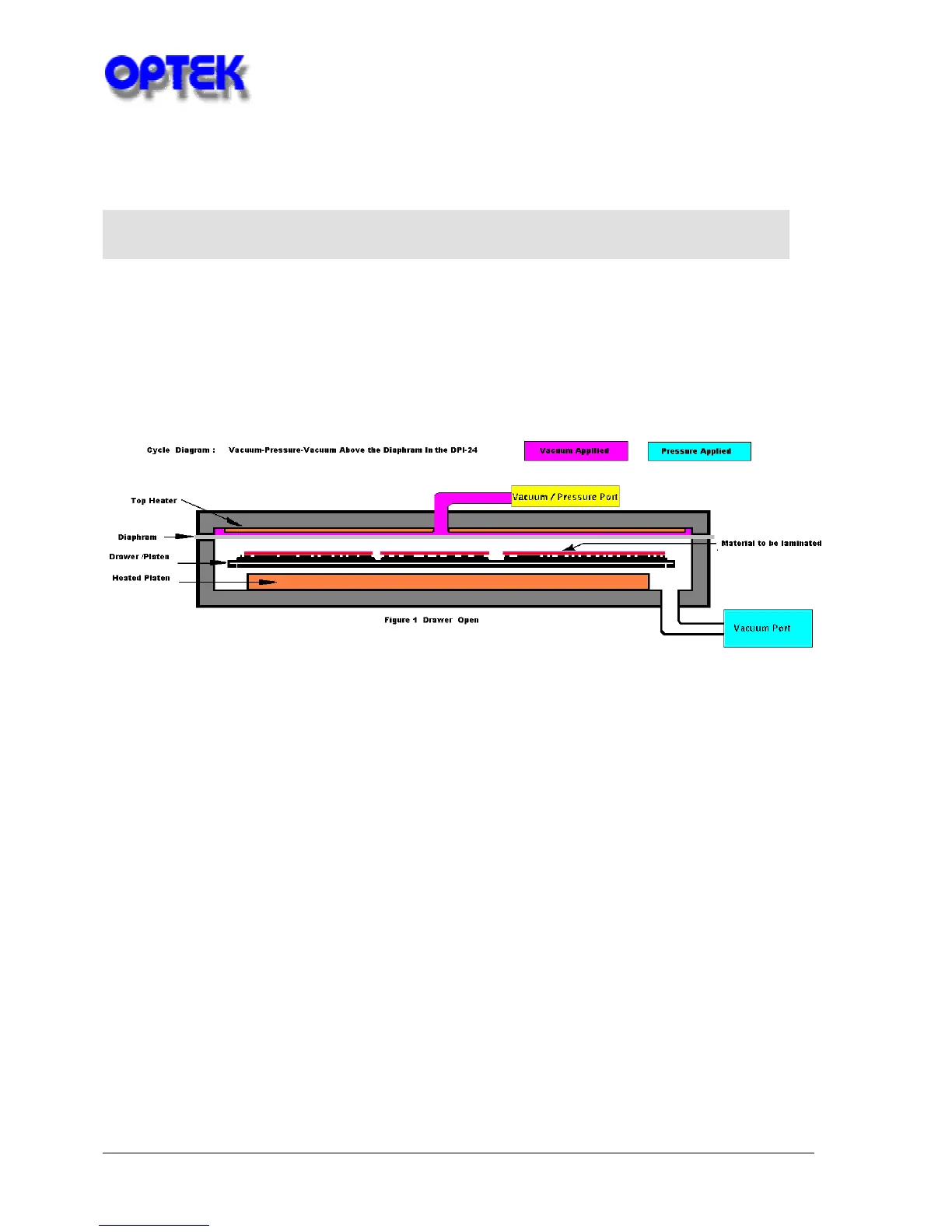

The following is an explanation and diagram

of the operation of the DPL-24 differential pressure laminator.

When the DPL-24 is turned on, two proportional controllers independently

drive the top and bottom heaters to the heat the diaphragm and platen to the

temperatures set on the front panel. After a brief warmup time, the laminator is

ready for use.

The drawer is pulled open to allow access to load the vulcanized rubber platen

with materials ready for lamination. Products of differing thicknesses and

geometries can be intermixed during a cycle if adequate “hold-down” techniques

are employed. The layered material is placed on the platen mounted in the

sliding drawer. When the drawer is closed, the platen is positioned in the

vacuum chamber, and an O-ring seal on the drawer face contacts the opening in

the vacuum / pressure vessel.

Before the beginning of the cycle there is a vacuum drawn above the

diaphragm. Air at atmospheric pressure is in bottom of the vessel, pushing the

diaphragm upwards. As shown in figure 1, the diaphragm is up above the material

on the drawer platen. The drawer platen is spring loaded upwards to allow the

drawer to be opened and closed.

Loading...

Loading...