OP175 System Installation, Operation & Maintenance 14

The only routine maintenance required on the

system is periodic replacement of the carbon/

sediment pre-lters and the mineral addition

cartridge. The CTO-Q10 cartridges should be

changed every 3-6 months depending on water

usage. In areas with high levels of sediment and

other contaminants the CTO-Q10 cartridges may

require more frequent changes. The mineral

addition cartridge should be changed when the

Optimized Water TDS drops.

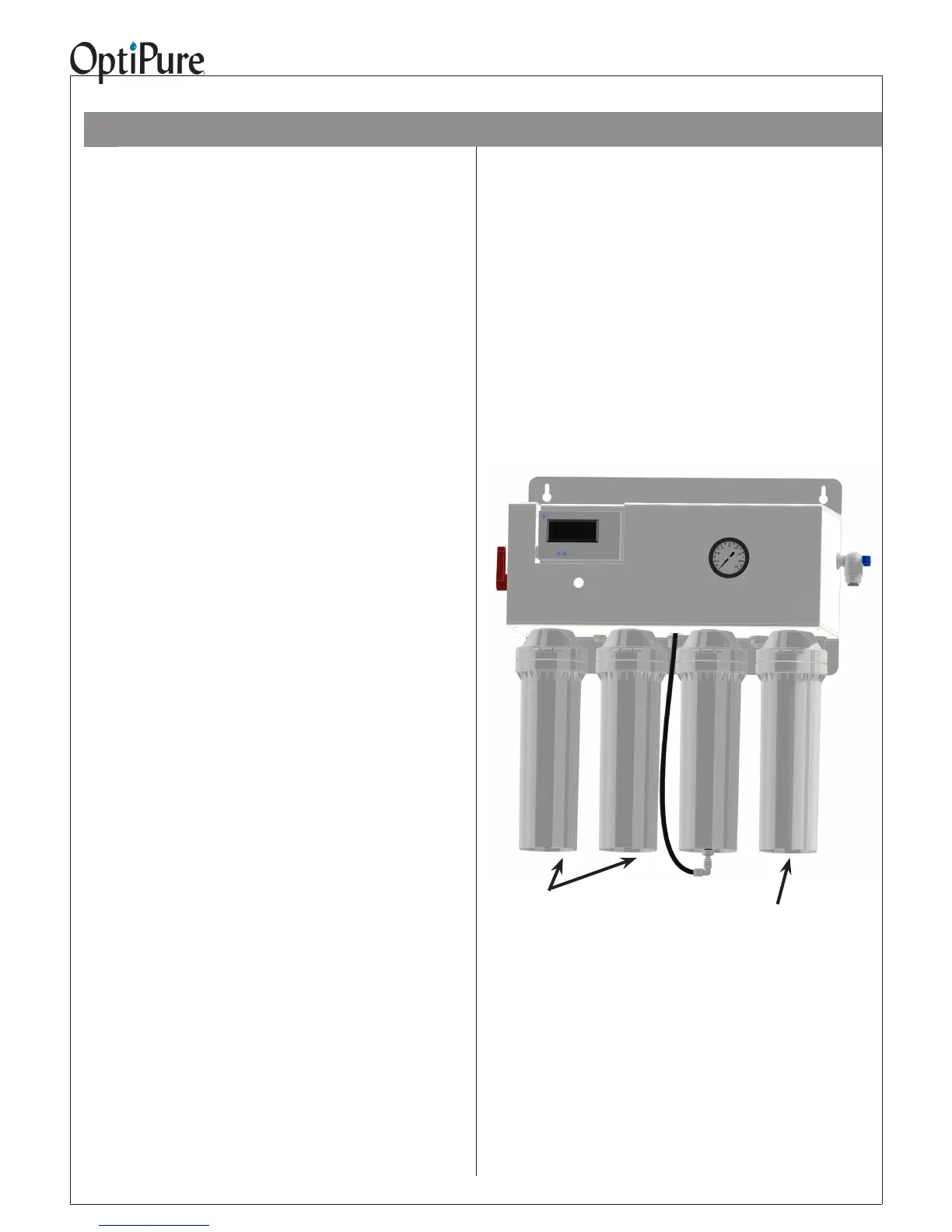

Pre-Filter change procedure

1. Either close the Water Supply Valve (shutting

off all water ow), or put the Emergency

Bypass Valve (on the Processor) in the

System Bypass position (allowing untreated

water to continue to ow to the equipment).

2. Wait a moment for system pressure to drain

off.

3. Once the system pressure has been relieved,

remove the two CTO-Q10 cartridges by

turning a quarter-turn to the left and pulling

down on the cartridge.

4. Install the new CTO-Q10 cartridges into

the QT heads by aligning the notches and

pushing up, then turn a quarter-turn to the

right.

5. If it is necessary to replace the Mineral

Addition Cartridge, repeat steps 4 - 5 for the

Mineral Addition Cartridge.

6. Install a piece of 3/8” tubing in the Processor

Sample Port valve, open the Sample Port,

and direct to a bucket or drain.

7. Turn the Tank Inlet Divert Valve to the Bypass

Mode (Handle Pointing UP).

8. Open the Water Supply Valve and put the

Emergency Bypass Valve in the “SERVICE”

position, allowing water to run into the new

Pre-Filter cartridges and purge air through

the system and out the Sample/Flush Port to

drain.

9. Once the air has been purged and lters

ushed, close the Sample Port valve and

return the Tank Inlet Divert Valve to the

Normal position (handle horizontal or down).

9. Check for leaks.

Optional Post-treatment cartridge change

procedure

(if applicable)

1. Close the ball valve at the inlet to the Post-

Treatment assembly.

2. Remove the existing cartridge and discard.

3. Install the new cartridge.

4. Open the ball valve and the RP pump should

actuate lling the housing with water.

Routine Maintenance: Filter Change Procedure

CTO-Q10 Pre-

Filters

PN: 300-05828

Change Every

3 to 6 months

MA-Q10 Mineral Addition

Cartridge

PN: 300-05850

Loading...

Loading...