11

English

Introduction

A welding helmet is a type of headgear used when performing certain types of welding to

protect the eyes, face and neck from flash burn, ultraviolet light, sparks, infrared light, and

heat. The helmet consists of several parts (see spare parts list). An automatic welding filter

combines a passive UV and a passive IR filter with an active filter, the luminous transmittance

of which varies in the visible region of the spectrum, depending on the irradiance from the

welding arc. The luminous transmittance of the automatic welding filter has an initial high value

(light state). After the welding arc strikes and within a defined switching time, the luminous

transmittance of the filter changes to a low value (dark state).

Safety instructions

Please read the operating instructions before using the helmet. Check that the front

cover lens is fitted correctly. If it is not possible to eliminate errors, you must stop

using the cartridge.

Precautions & protective restrictions / Risks

During the welding process, heat and radiation are released, which can cause damage to

the eyes and skin. This product offers protection for the eyes and face. When wearing the

helmet, your eyes are always protected against ultraviolet and infrared radiation, regardless

of the shade level. To protect the rest of your body, appropriate protective clothing must also

be worn. In some circumstances, particles and substances released by the welding process

can trigger allergic skin reactions in correspondingly predisposed persons. Materials that

come into contact with skin may cause allergic reactions to susceptible persons. The protective

welding helmet must only be used for welding and grinding and not for other applications.

Optrel assumes no liability when the welding helmet is used for purposes other than intended

or with disregard for the operating instructions. The helmet is suitable for all established welding

procedures, excluding gas and laser welding. Please note the recommended protection

level in accordance with EN169 on the cover.

The helmet does not replace a safety helmet. Depending on the model, the helmet can be

combined with a protective helmet. The helmet can affect the field of view due to constructive

specifications (no view on the side without turning the head) and may affect a color perception

due to the light transmission of the auto darkening filter. As a result, signal lights or warning

indicators may not be seen. Further there is an impact hazard due to a larger contour (head

with helmet on). The helmet also reduces the audio and heat perception.

Sleep mode

The cartridge has an automatic switch-off function, which increases the service

life. If no light falls on the solar cells for a period of approx. 10 minutes, the cartridge

automatically switches off. To reactivate the cartridge, the solar cells must be briefly

exposed to daylight. If the shade cartridge cannot be reactivated or does not darken

when the welding arc is ignited, the cartridge must be judged faulty.

Warranty & Liability

The warranty conditions can be found in the instructions from the national sales

organisation of Optrel. Please contact your dealer for further information concerning

this matter.

The warranty only applies to material and manufacturing defects. In the event of

damage caused by improper use, unauthorised intervention or use for a purpose

that is not intended by the manufacturer, the warranty and liability will be null and

void. Likewise, liability and the warranty are no longer valid if spare parts other than

those sold by Optrel are used.

Expected Lifetime

The welding helmet has no expiration date. The product can be used as long as no

visible or invisible damage or functional problems occur.

Usage

1. Head band. Please adjust the upper adjusting strap to your head size. Depress

ratchet knob and rotate until the head band sits firmly yet comfortably.

2. Eye distance and helmet inclination. The distance between the cartridge and

the eyes is adjusted by releasing the locking knobs. Adjust to the same extent

at both sides without jamming. Then retighten the locking knobs. The helmet

inclination can be adjusted using the rotary knob.

3. Shade level. The shade level can be selected between 9 and 13.

4. Sensor bar. The fitted sensor bar reduces the openings of the sensors and

therefore the influence of external light, e.g. reflections. The sensor bar can be

removed using your finger nail.

5. Delay. The opening knob allows to select an opening delay from dark to light.

The knob allows infinite adjustment from dark to light between 0.1 to 1.0 s which

protects the eyes.

6. Sensitivity. Use the sensitivity knob to set the light sensitivity according to the

welding arc and the ambient light.

Cleaning and desinfection

The shade cartridge and the front cover lens must be cleaned with a soft cloth at regular

intervals. No strong cleaning agents, solvents, alcohol or cleaning agents containing

scouring agent must be used. Scratched or damaged lenses must be replaced

Storage

The welding helmet must be stored at room temperature and at low humidity.

Replacing the the front cover lens

Push in one side clip to release the front cover lens and then remove it. Attach the new

front cover lens to one side clip. Pull the front cover lens round to the second side clip

and clip in place. This action requires some pressure to ensure that the gasket on the

front cover lens has the desired effect.

Removing/installing the cartridge (see cover)

1. Unlock the cartridge retention spring as shown

2. Carefully tilt the cartridge out

The cartridge is installed in the reverse order.

Troubleshooting

Cartridge does not darken

→ Change the sensor bar position

→ Clean sensors or front cover lens

→ Check the light flow to the sensor

Poor vision

→ Clean the front cover lens or cartridge

→ Increase the ambient light

Welding helmet slips

→ Adjust/tighten the head band

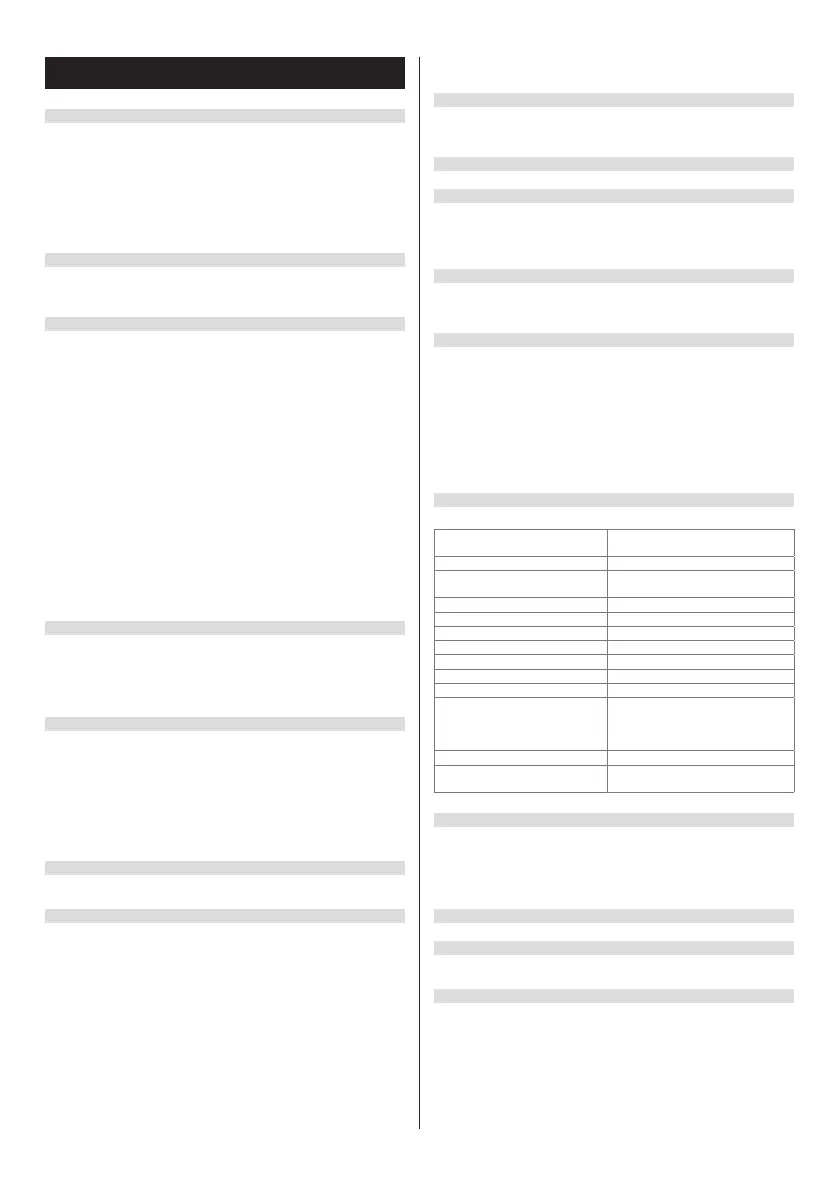

Specifications

(We reserve the right to make technical changes)

Shade Level 4 (light mode)

9 – 13 (dark mode)

UV/IR protection Maximum protection in light and dark modes

Switching time from light to dark 0,00015s (23°C / 73°F)

0,00010s (55°C / 131°F)

Switching time from dark to light 0.1s - 1.0s

Dimensions of cartridge 90 x 110 x 7mm / 3.55 x4.33 x 0.28“

Dimensions of field of vision 50 x 100 mm / 1.96 x 3.94“

Power supply 2 x CR2032 (replaceable)

Weight 460g / 16,226 oz

Operating temperature -10°C – 70°C / 14°F – 157°F

Storage temperature -20°C – 80°C / -4°F – 176°F

Classification as per EN379 Optical class = 1

Light scatter = 1

Homogeneity = 1

Angle of vision dependency = 2

Standards CE, ANSI Z87.1, EAC, compliance with CSA Z94.3

Additional markings for PAPR version

(notified body CE1024)

EN12491 (TH3 in combination with e3000, TH2 for

versions with hardhat and e3000).

Spare parts (see cover)

1. Cartridge incl. satellite

2. Front cover lens

3. Inner protection lens

4. Head band with fastener

5. Sweat band

Declaration of conformity

See the Internet address on the last page.

Legal information

This document complies with the requirements of EU Regulation 2016/425 section 1.4 of

Annex II.

Notified body

For detailed information see last page.

Loading...

Loading...