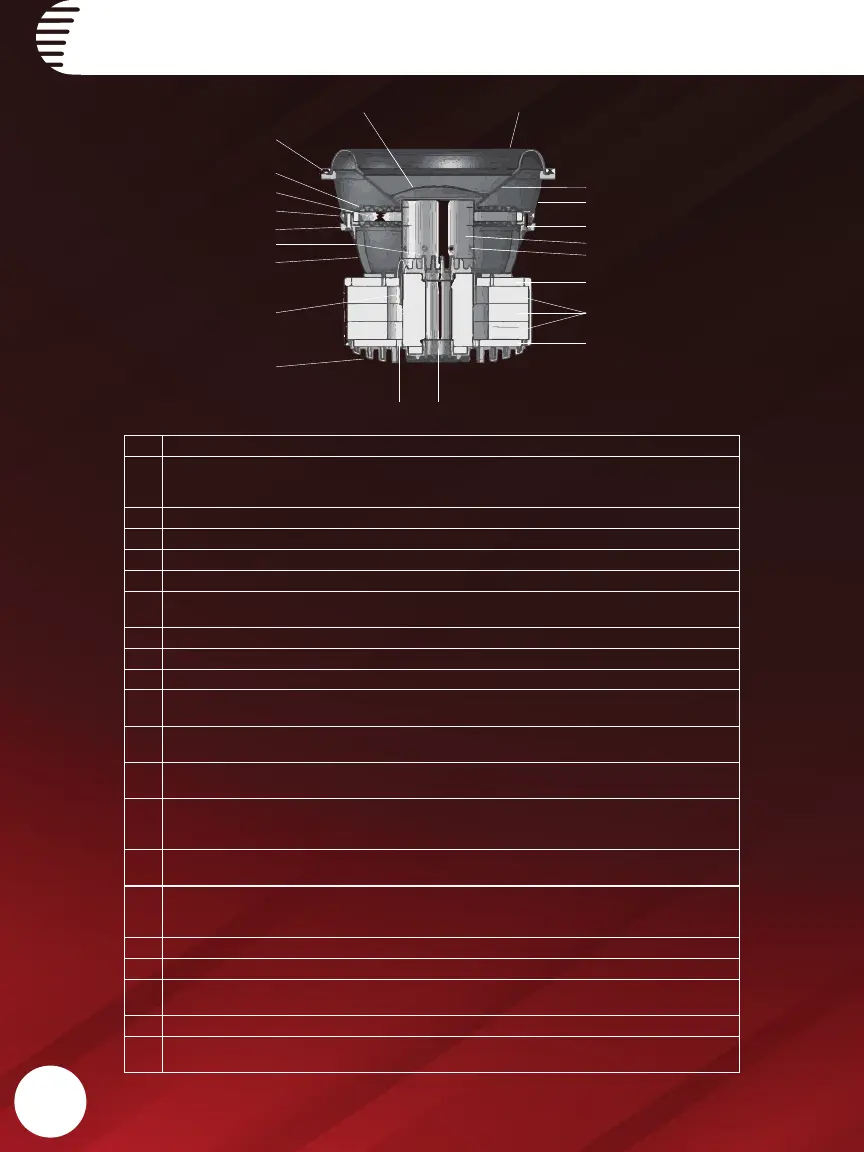

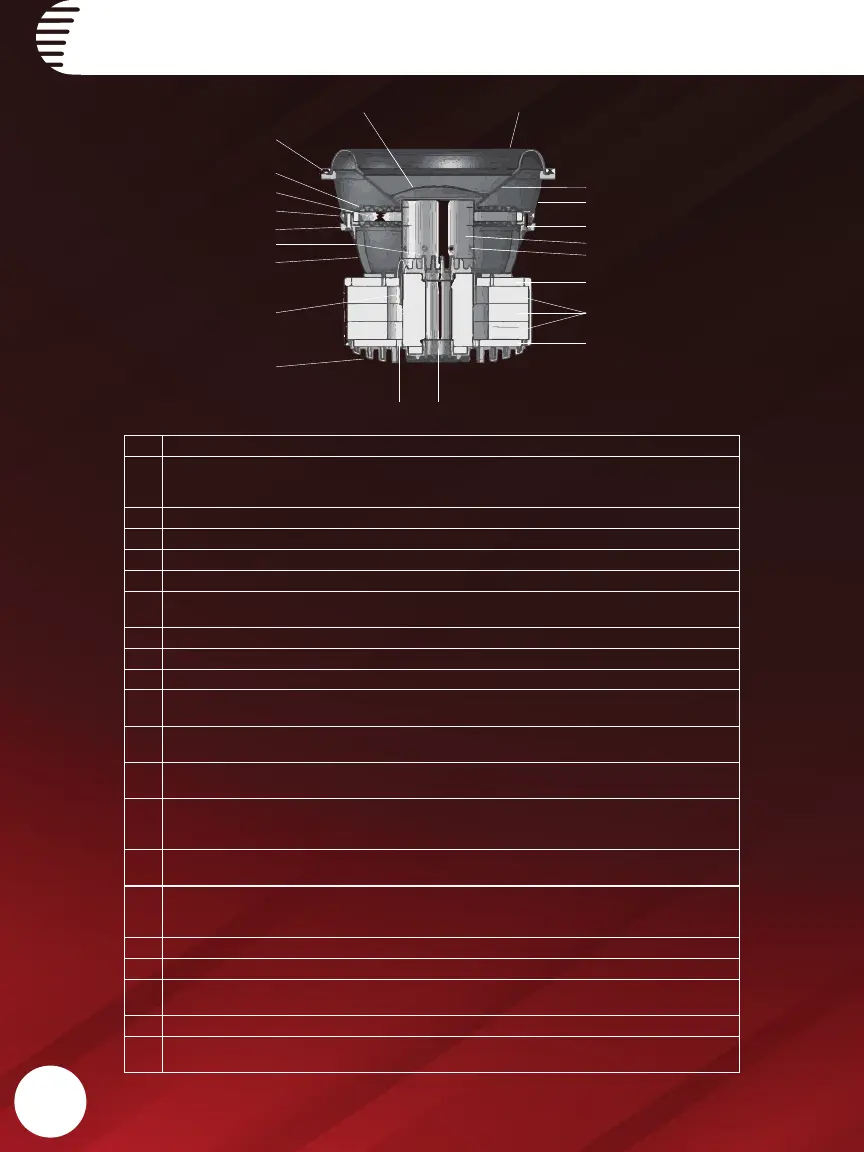

FEATURES

3

21

4

3

5

6

7

8

9

10

13

14

16

15

17

18

19

20

21

12 11

1 Polypropylene dust cap - moisture and UV resistant.

2 Tall, wide, balanced, NBR Foam (high density expanded polyester foam) surround for

linear controlled long excursion using a Tri Radius symmetrical edge design optimized

on non-linear FEA.

3 Paper cone - moisture and UV resistant.

4 Custom Cast Aluminum frame.

5 Spider ring attachment screws. Part of re-cone feature (8 hex screws)

6 aluminum voice coil former (10” uses 3” voice coil former, 12 & 15 use a 4” voice coil former)

7 Venting in Voice coil former. Part of the enhanced voice coil cooling system (forced

convection)

8 11mm Steel front plate.

9 Large 3 stack ceramic magnets (10” 264 oz 12/15” 445 oz)

10 11mm Steel back plate/pole piece T yoke assembly

11 1.25” vent. Part of the enhanced voice coil cooling system (forced convection - aluminum

heat sinking - shorting rings to reduce inductive heating)..

12 Voice coil gap vents. Part of the enhanced voice coil cooling system (forced convection -

aluminum heat sinking -shorting rings to reduce inductive heating).

13 Cast aluminum rear pole piece heat sink with ns and vent holes. Part of the enhanced

voice coil cooling system (forced convection - aluminum heat sinking)

14 High temperature (Polyester Amide Resin Coated) Copper clad Aluminum voice coil

wound on an aluminum former (10” uses 3” voice coil, 12 & 15 use a 4” voice coil) Dual 2

and 4 ohm voice coils available

15 Screen meshed areas to allow venting below spider to and keep foreign object out of the

voice coil gap.

16 Cast aluminum top pole piece heat sink with ns and vent hole. Part of the enhanced

voice coil cooling system (forced convection-aluminum heat sinking-shorting rings to

reduce inductive heating).

17 Bottom at interlaced Conex spider with stitched and looped tinsel leads attached.

18 Custom allen head screw terminals. A pair on each side (one pair for each voice coil).

19 Spider spacer and spider mounting ring assembly part of eld re-cone kit attachment

method. (eight allen head screws).

20 Top at interlaced Conex spider.

21 Surround clamp ring, part of eld re-cone kit attachment method. (eight allen head

screws).

Loading...

Loading...