38

-

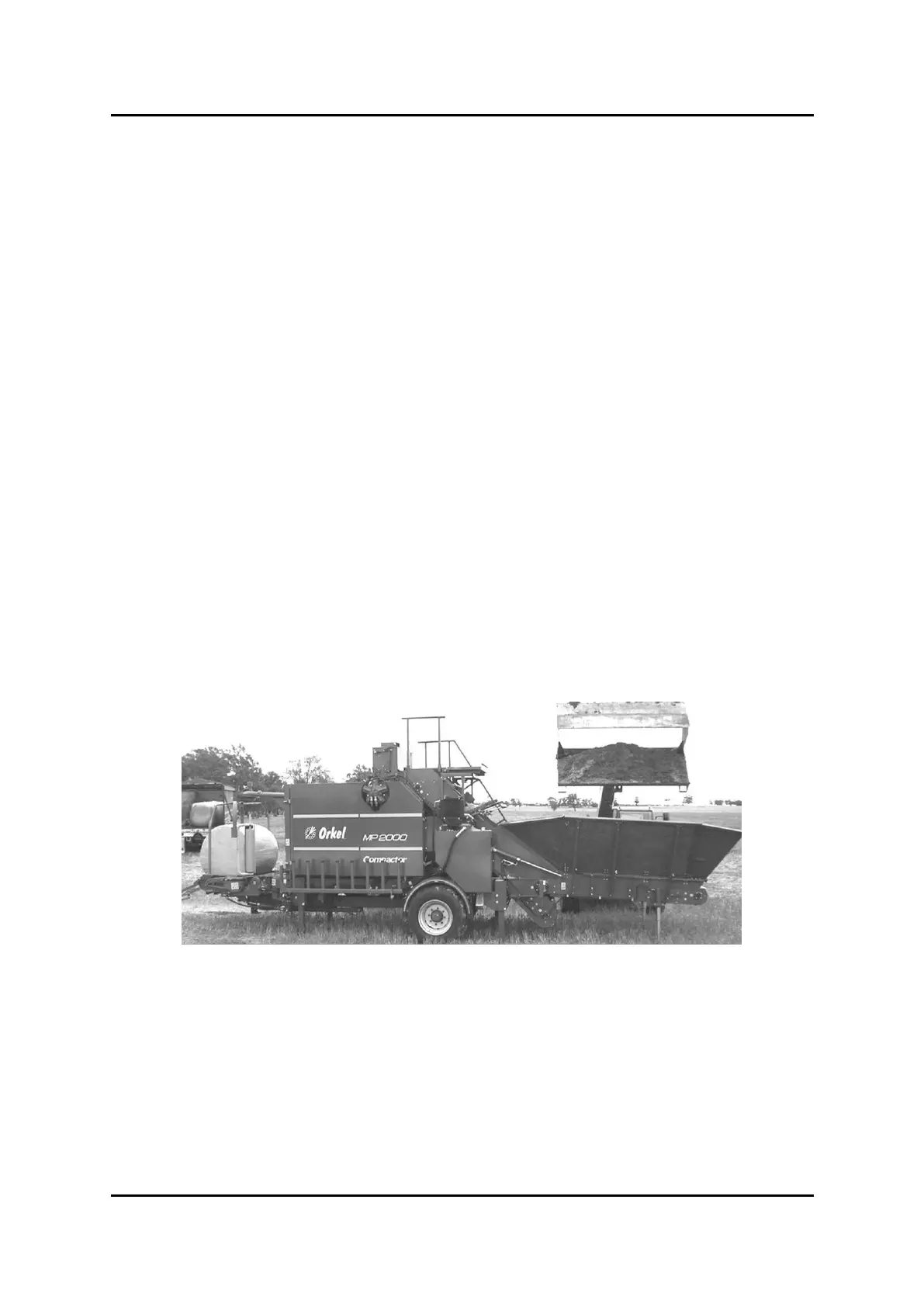

The machine is operang automacally , supervised by the control box. The operators main task is to ensure

there is enough material in hopper, and stove away bales produced.

The material is loaded on the hopper/feeder by a wheeled loader or excavator or similar. If the compactor is

equipped with a low - built hopper, the material can be dumped directly in the hoppers tray. The material is

then transported by a conveyor - belt into the chamber, and being pressed to a bale. The amount of material

being fed into the chamber is controlled by speed - regulaon sensors and parameters set in control box.

All funcons in the baling process can be adapted and opmized, depending on which material is being

pressed/baled. The hopper has a capacity of 7 cubic meter of loose material. The hopper/feeder is also de-

tachable and the elevator might be lled directly by a conveyor - belt or a similar device.

When the pressing cycle is nished, a net or widelm from the HiT - unit is being added to the bale in the

chamber. By doing this the bale keep it’s shape while being unloaded from chamber and transported on to

the wrapper table. When the bale is loaded onto the wrapper table, the chamber tailgate is closing at the

same me and a new bale is in progress.

The wrapping cycle start automacally when a bale is registered on the table. Any loss from the baling pro-

cess is transported back to the elevator by a conveyor belt (belt under), and fed back into the process. Pa-

rameters like; chamber pressure, amount of widelm/net and number of layers of plasc lm being added

on the wrapper table, and more, can all be set in the control box.

-

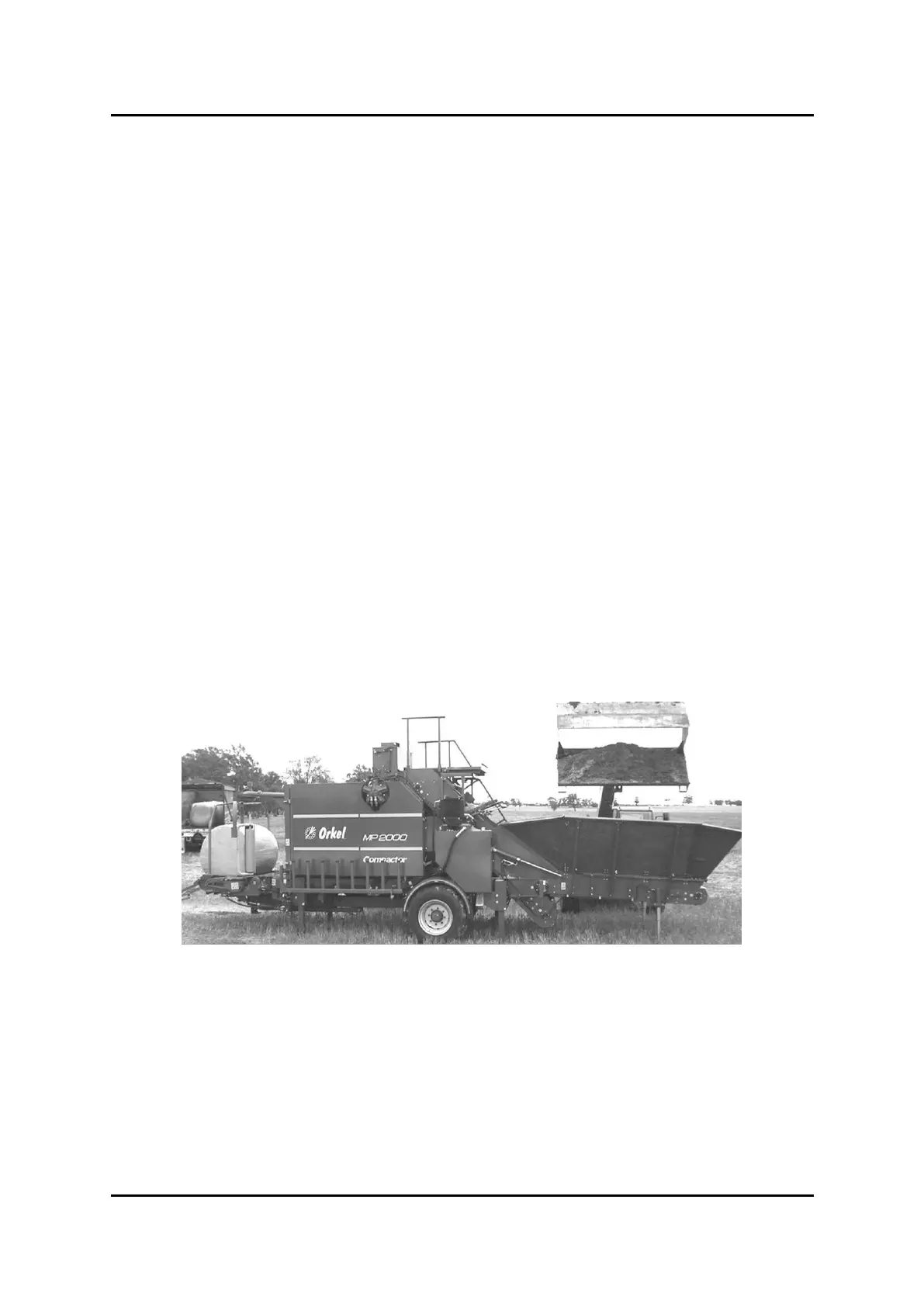

Compactor main secons, le side view.

1. Hopper

2. Elevator/feeder

3. Press chamber

4. Wrapper table

5. HiT (Hi -tension) - Unit

4

3

2

1

5

Loading...

Loading...