44

4.5 --

-

Binding the bale in chamber with plasc lm or

net is performed by the HiT unit (High Tension)

on top of the machine.

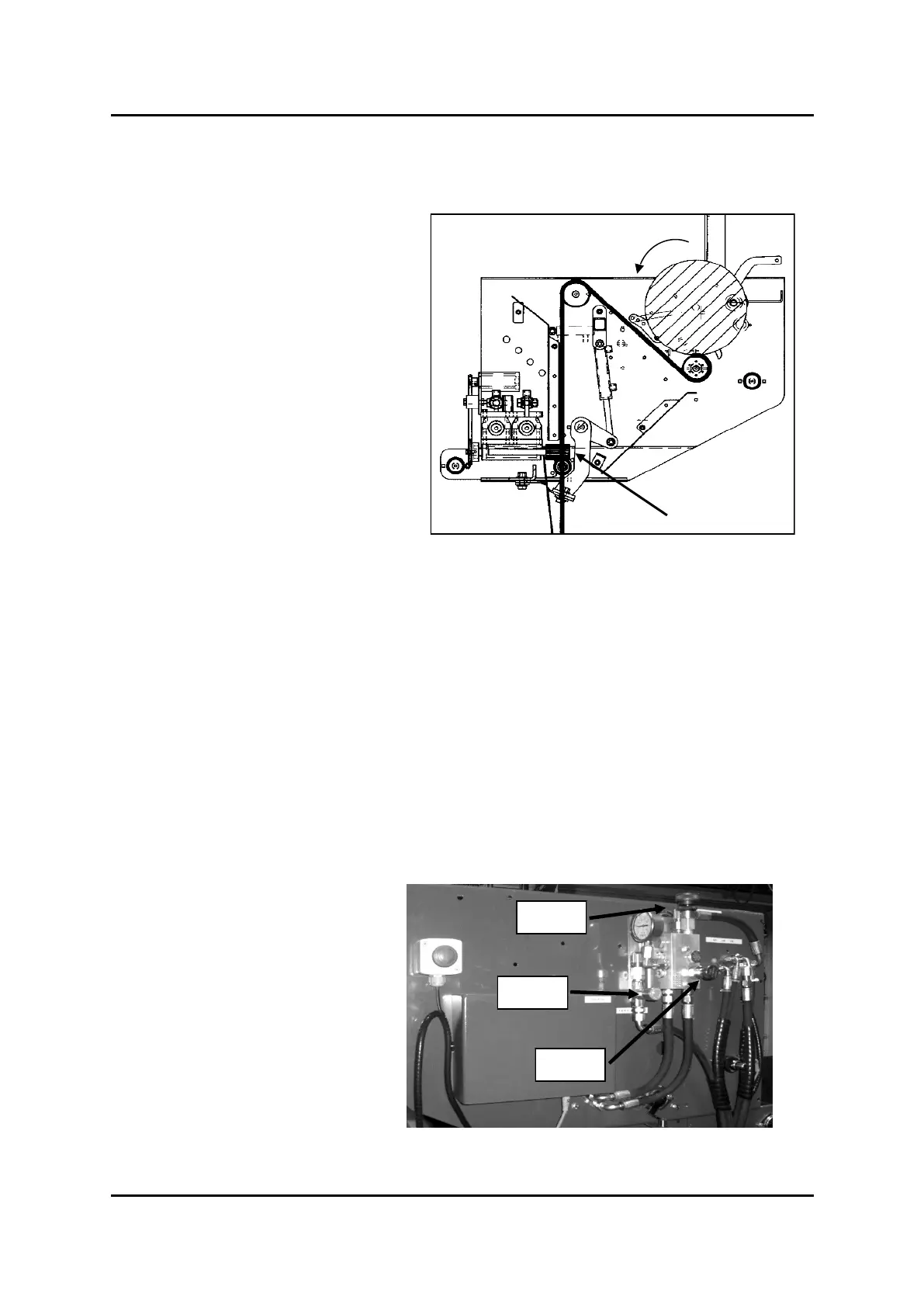

When installing a new roller, guide the lm as

shown in gure 1. ( emphasized line )

Aer lling up the chamber, and a pre set chamber pressure value have been reached. The feeder motor in

HiT unit starts and lm/net is being fed into the chamber. When the rope end is long enough, the bale create

a drag on the lm/net and start pulling it out. At the same me, the feeder motor stops and feeder arms is

moving outwards. A freewheel in feeder motor allow the lm/net to enter the chamber without any prob-

lem.

The net-brake is then being acvated making a pre-tension applied to the lm/net. This ensures a ght and

even binding of the bale in chamber. Aer added a pre set number of lm/net layers to the bale, the cham-

ber tailgate is opened and the bale is unloaded. The bale is then transferred to the wrapper table by a

transport chain. When entering the wrapper table, the tailgate is closing and a new bale is in progress.

-

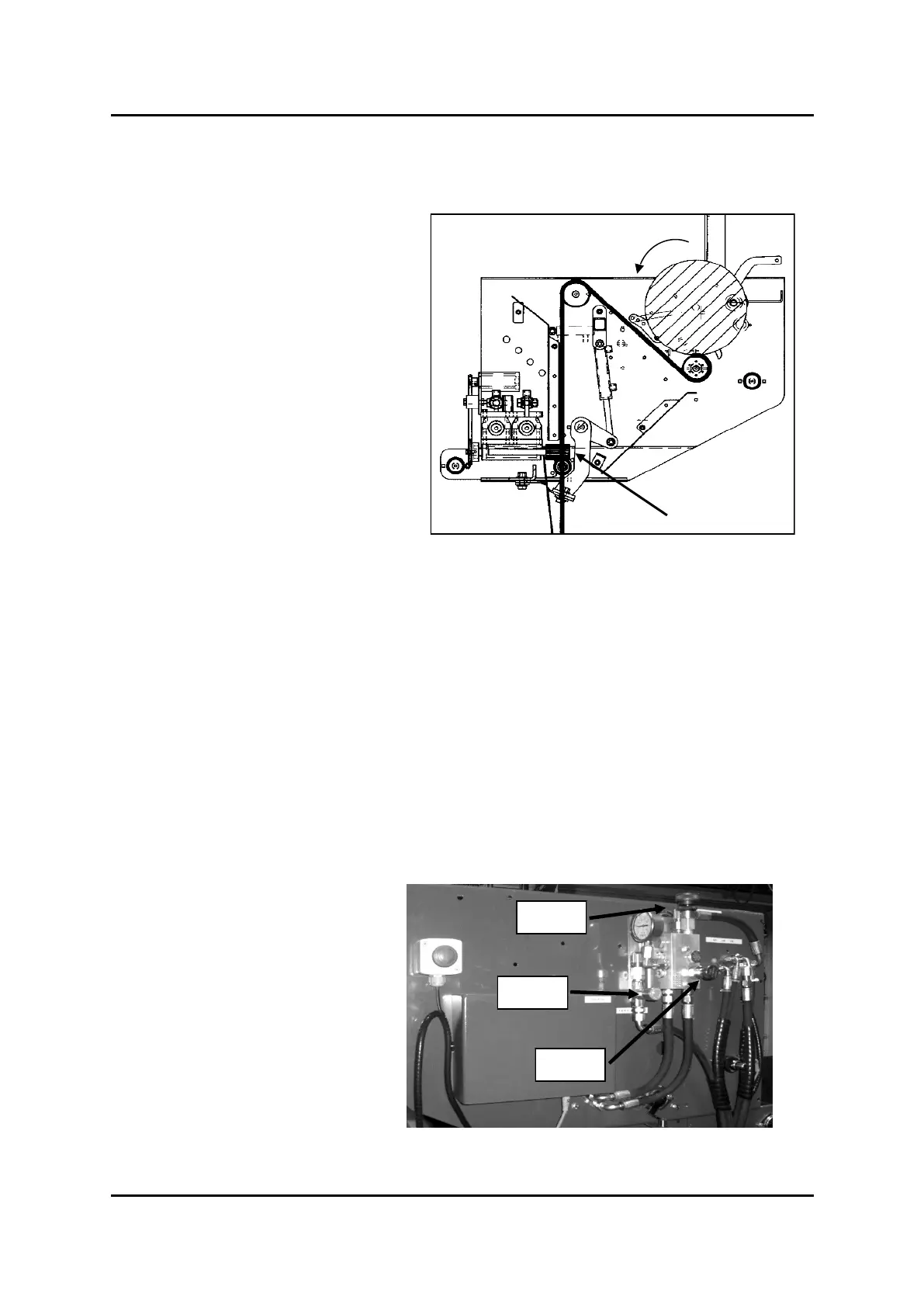

61 Plasc lm, brake

62 Plasc lm, speed

63 Net/lm brake, disengage

Valve:63

Valve:62

Valve:61

Figure 1.

Feeder rolls

Loading...

Loading...