62

Make sure you have

received the right type before dismounng start.

The distributed load to the bearings will not be even, and therefore the wear is not

evenly distributed on the bearing. Clean the bearing carefully to get the right impression of the

rate of wear, before inspecon.

A quick control of the degree of wear (clearance) might be

done with a bar and a dial gauge. If no excessive wear is

found, there’s no need to further dismantling of the bear-

ings.

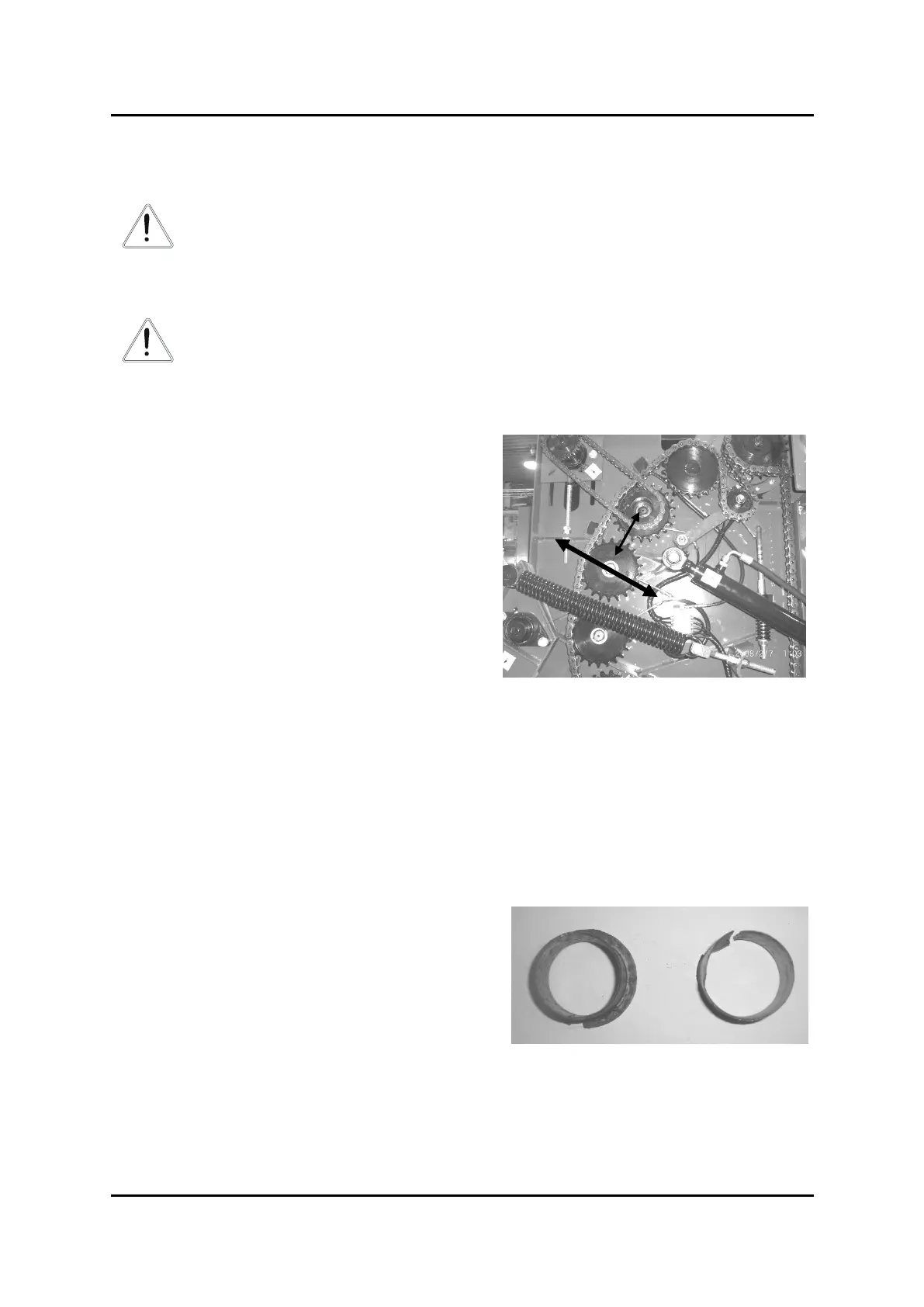

The load of force onto the bearings is illustrated with

in picture to the right.

New bearing: 40 mm inside diameter, 44mm outside diameter

Defect bearing: ≥ 42,2 mm inside diameter. Measure the diameter several places to get the correct impres-

sion of the bearing ovality.

New bearing: 50 mm inside diameter, 55 mm outside diameter

Defect bearing: ≥ 52,7 mm inside diameter. Measure the diameter several places to get the correct impres-

sion of the bearing ovality.

The material thickness in bearings should under no circum-

stances be

This to avoid serious damage harmed to the rollers axle’s,

and subsequent mechanical break-down.

Good pracce is to change the bearings before reach-

ing the maximum degree of wear and tear.

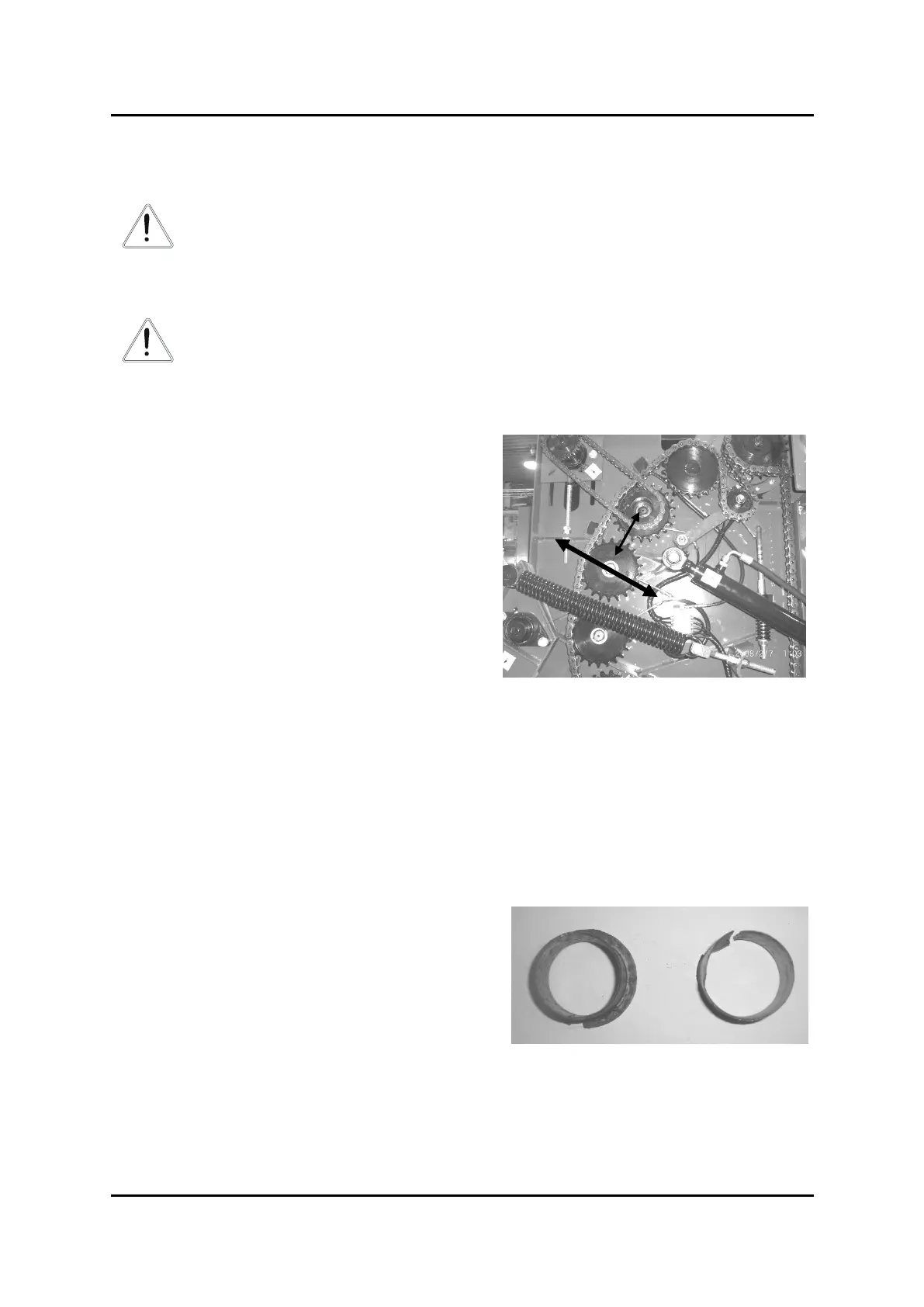

Example in picture 1. New bearing (le) and worn out defect bearing

Picture 1, Slide bearing

Load of force - slide bearings.

Loading...

Loading...