64

- --

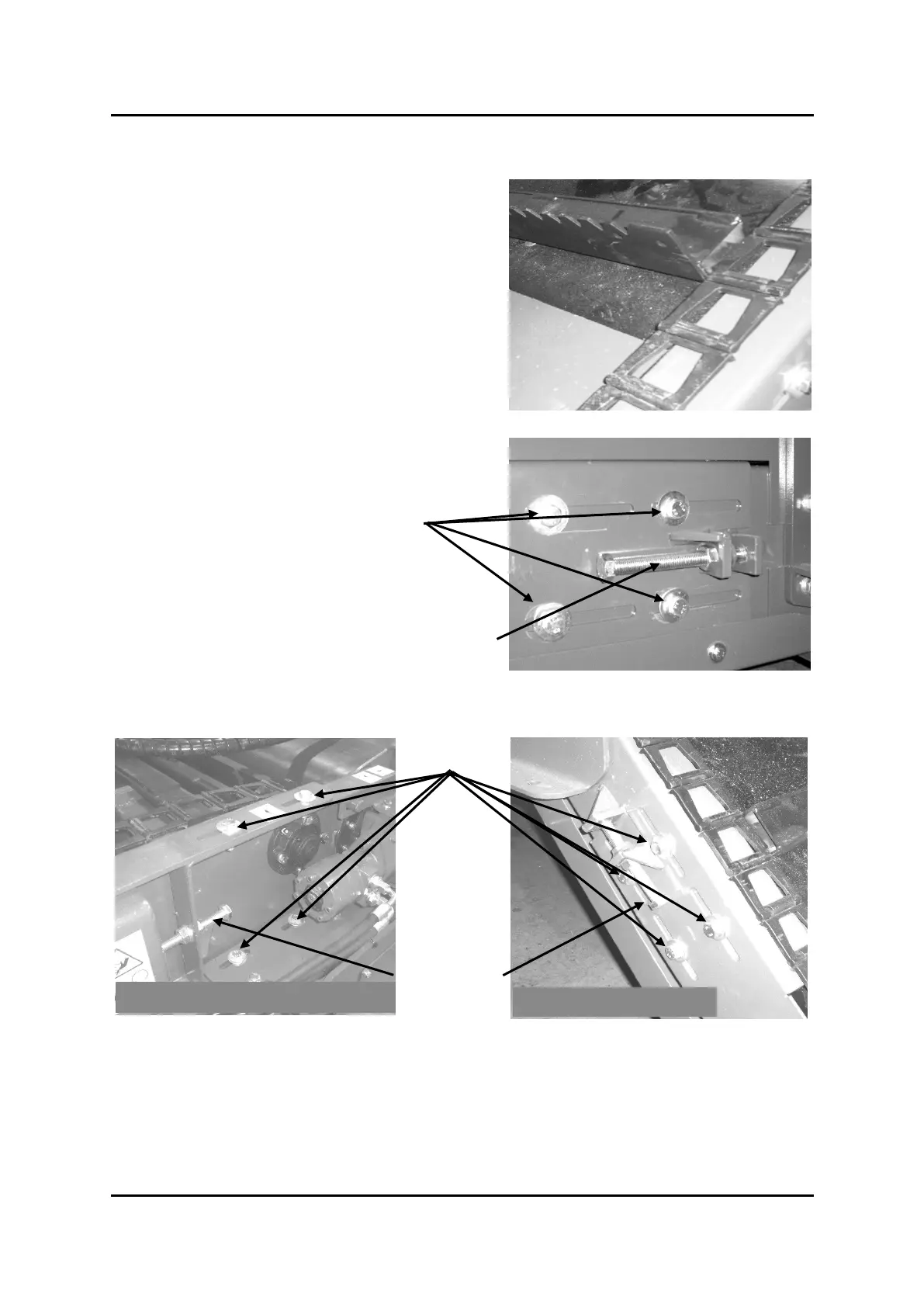

These belts is of chain type with welded dogs. Check the belt

tensioning and look for uneven wear from oblique angel on

belts.

Same procedure on all the three belts. Tighten the belt ten-

sioner, unl all clearance is gone. Tighten equally on both

sides, and check that the tracking of the belt is centred..

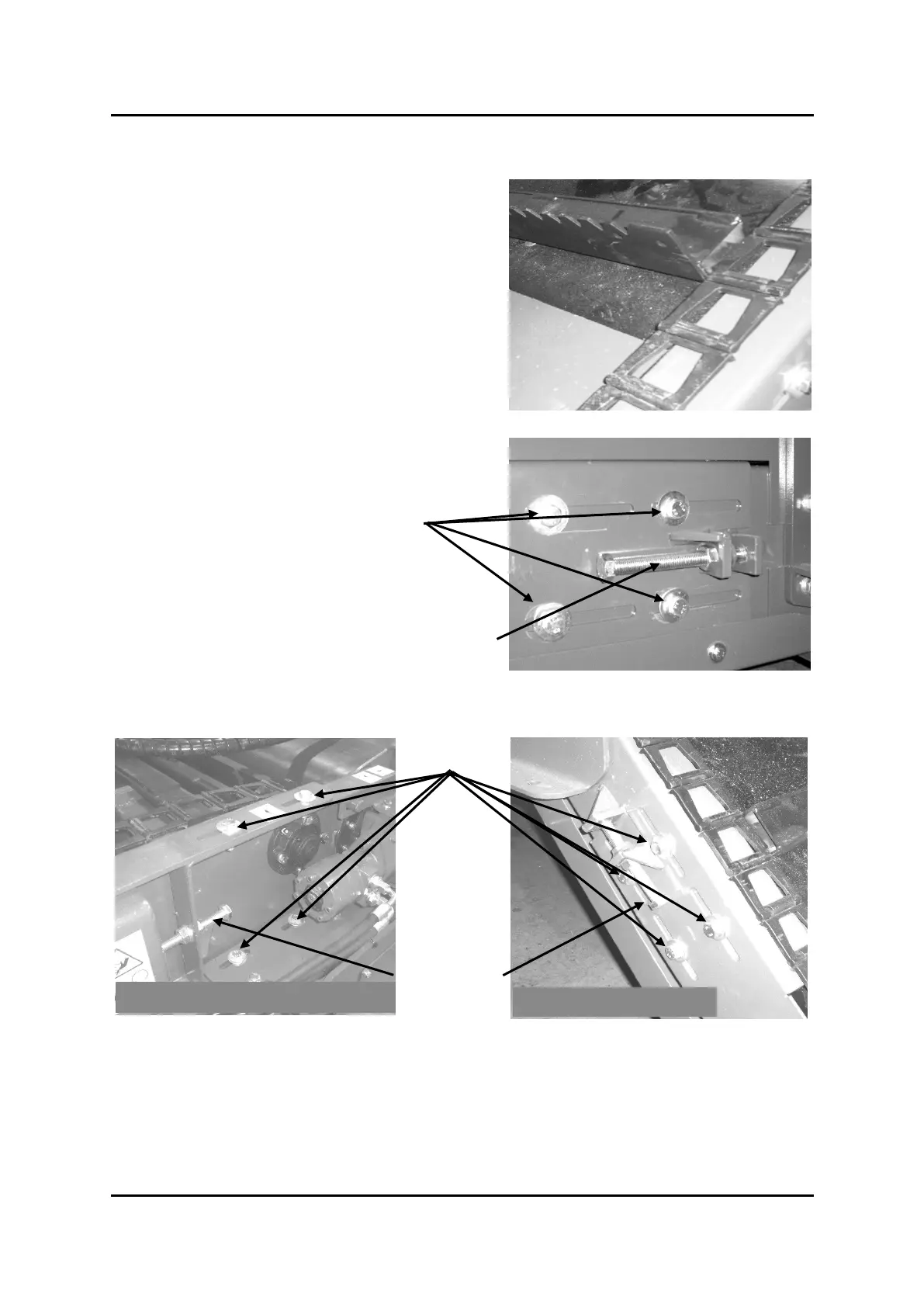

If the wear in the segments is too large to

ghten the belt properly, one segment

can be removed.

Loosen the four bolts holding the bracket.

Unghten the counter nut and ghten the

bolt on the chain tensioner unl correct

belt -tension is achieved. Adjust both

sides equal.

Tighten the counter nut and the aaching bolts on bracket.

-

The rollers in feeder table, elevator and belt under should be without deformaons and cracks. Check the

bearing clearances without belt tension. Replace worn ball -bearings and rollers.

Aaching bolt

x 4

Chain

Tensioner-bolt

Aaching bolt

x 4

Chain

Tensioner –bolt

Loading...

Loading...