67

-

The compactor is equipped with a fully automac lubricaon system. It lubricates the sleeve bearings

(grease) and the chains (oil).

A single piston pump driven by the hydraulic pressure, supply oil to the chains through brushes which is

mounted on strategic locaons. Each me the chamber tailgate opens, the piston is acvated and supply a

x amount of oil to chains.

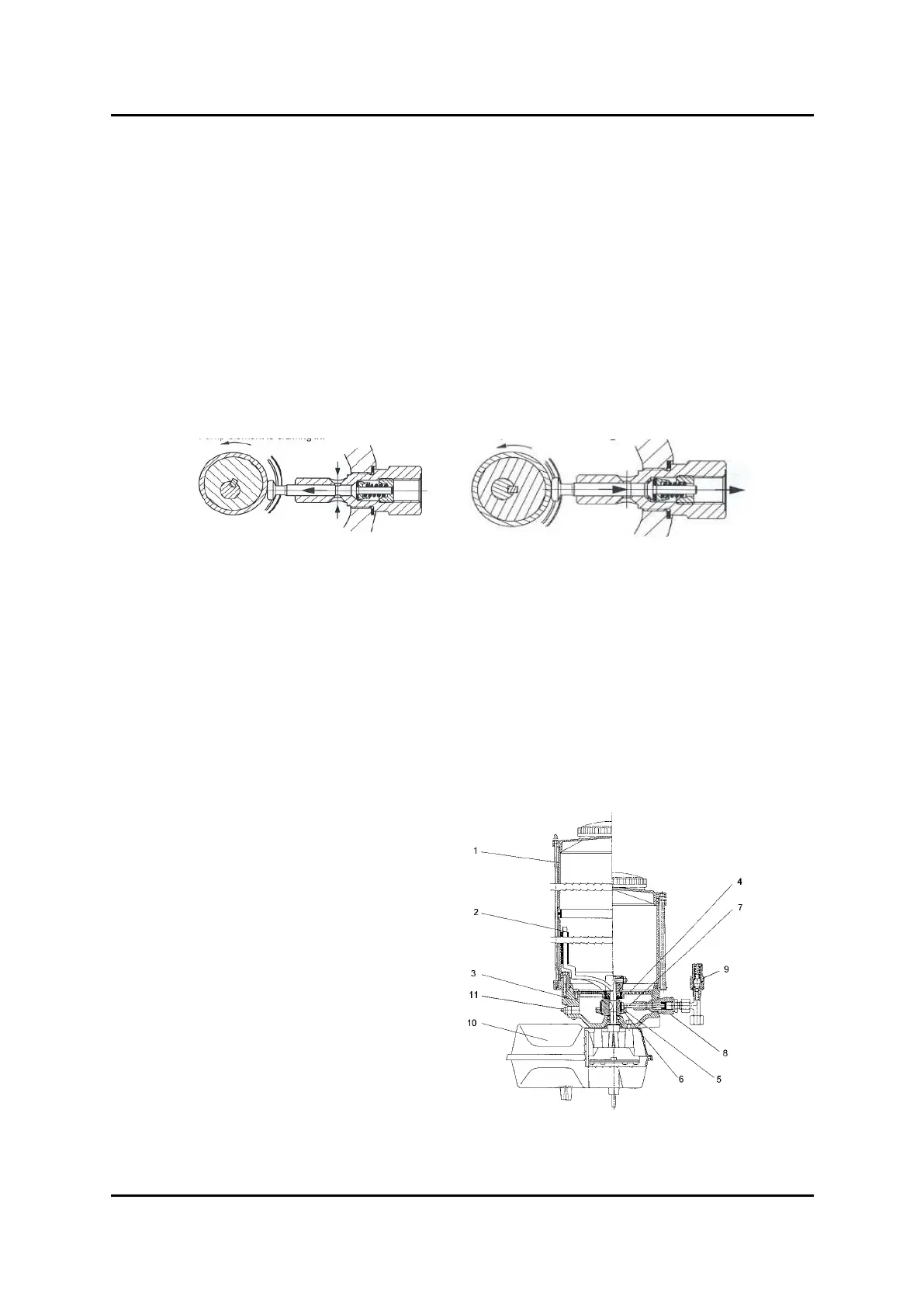

An electrical motor (connuous drive) runs an eccentric. The eccentric drive two single working pistons

which press a x amount of grease through a pressure relief valve, and further on to a main distributor. The

main distributor supply then grease to sub-distributors, which deliver the correct amount of grease to each

bearing. Not the same amount of grease to all bearings!

The grease lubricaon system is a progressive system. It operate all types of grease of NLGI kl. 2 type. See

recommended lubricants in chapter 5.2.6. A progressive lubricaon system, means that all the bearings is

lubricated one by one. This progressive system make the lubricaon system easily monitored trough a high

pressure relief valve. (nr.9, gure 1) If a lubricaon line to a bearing is clogged, the pressure will increase

(280 bar) and visible grease appears on the relief valve. Please check the pressure relief valve on a regular

base. If visual grease is present, a line or a distributor is clogged. An another malfuncon could be that a line

is broken, but then there’s no visual grease on the relief valve.

1. Reservoir, transparent

2. Srrer scrape

3. Sucon area, pump

4. Screen

5. Eccentric cam

6. Pressure ring

7. Delivery piston

8. Non return valve

9. Pressure relief valve

10. Motor (12V DC)

11. Rell nipple, male sleeve

Figure 1

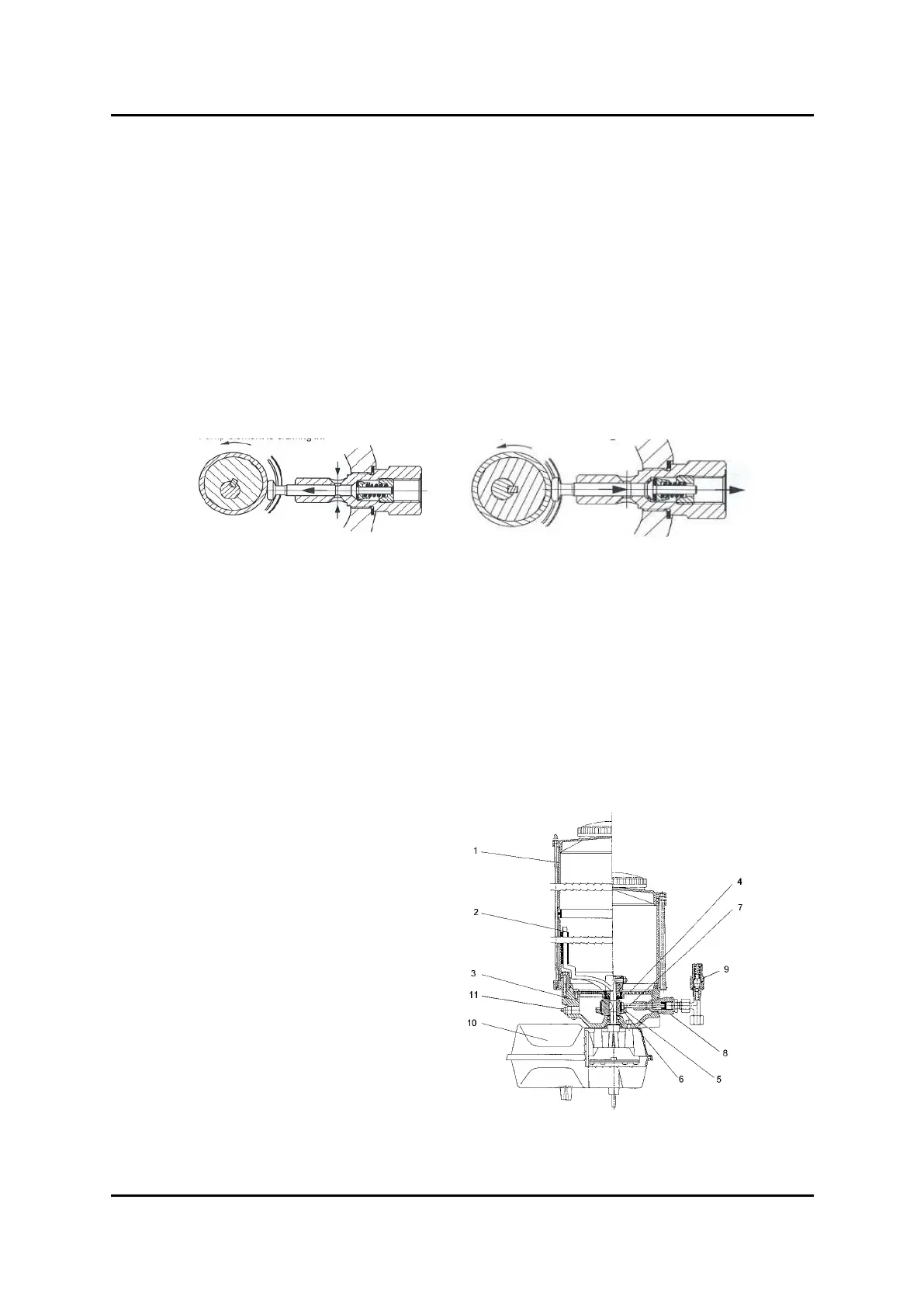

Pump element, sucon phase

Pump element, pressure phase

Loading...

Loading...