68

The slide bearings on chamber rollers is under huge stress and force during operaon. It’s of great

importance that the lubricaon system is in good working order.

Make sure the level of lubricants is always between max and minimum in the reservoirs. (Oil and Grease)

Check the level on a daily regular base, before start –up.

The grease lubricaon system is sensive to the inuence of external contaminaon, such as dust and dirt.

Keep the cap on and rell through the male sleeve nipple (nr.11 gure 1) when relling grease.

We recommend to purchase grease in larger containers. Pails of 20 litres/16kg’s in combinaon with

air or electrical operated tools for relling. Standard grease gun with 0,5 litres cartridges might also be used.

A grease gun for cartridges, with special nipple might be ordered as a opon. Part number: 58086

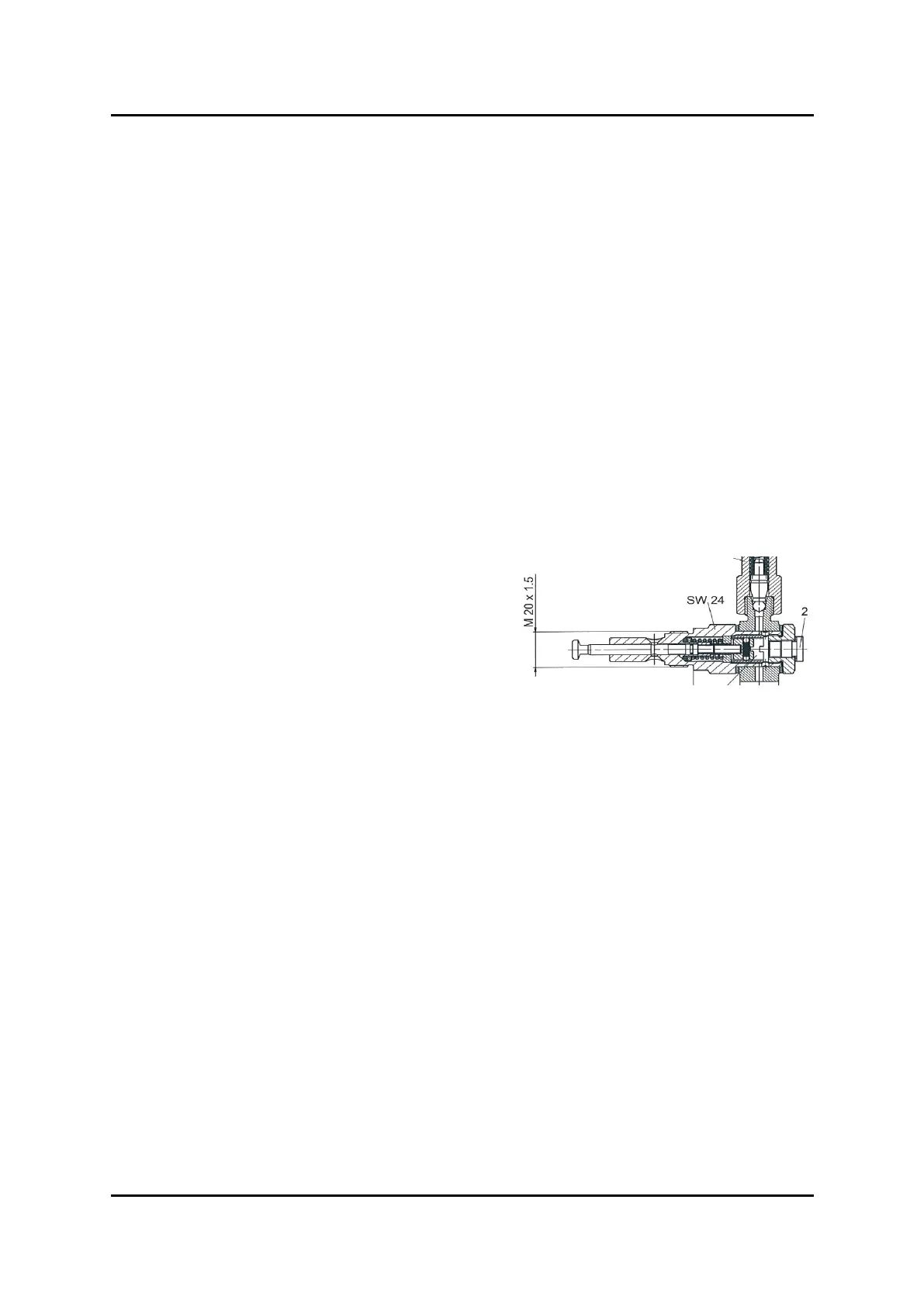

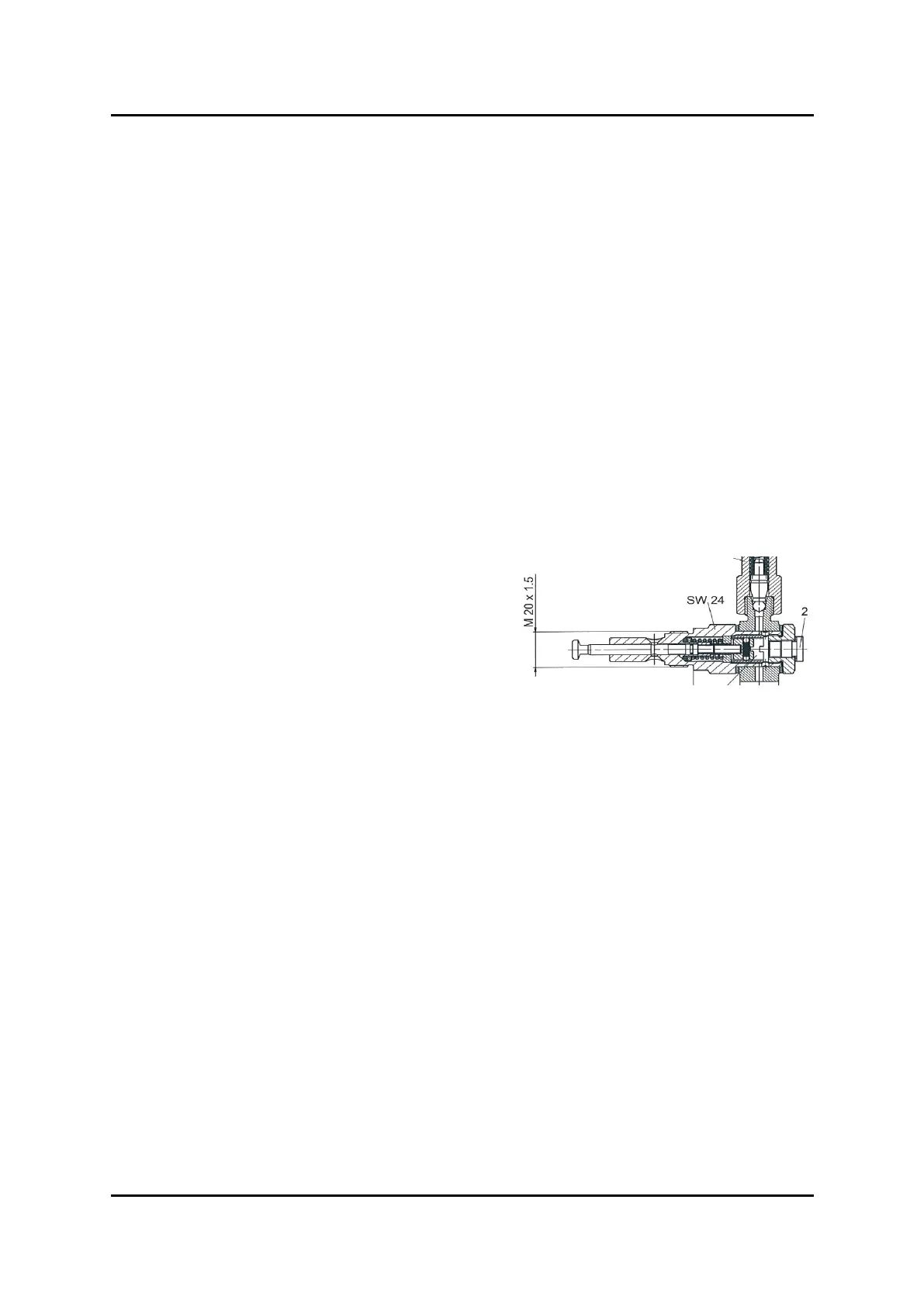

The grease lubricaon system is set to a maximum delivery of

29cm³. However one of the pumps is adjustable. (PE120V)

Remove plug (2) to get access to adjusting screw (3). By turn-

ing the screw clockwise, the amount is reduced. 1/2 turn on the

adjusting screw reduces the grease added by 0,013cm³. Please

conference Orkel Compaction if this is relevant.

If the level in reservoir is too low, it might be needed to bleed the system aer relling.

1. Disconnect the plasc pipeline, mounted under the pressure relief valve on the pump.

2. Acvate the funcon in the control box, unl a constant smooth ow from the outlet.

3. Reconnect the plasc pipeline in it’s original posion.

4. Acvate the funcon greaser in control box once more. (The pump will run as long as the buon in

control box is pressed)

All the parts of the BEKA - max system is maintenance-free. We although recommend a external cleaning of

the pump and lines from me to me with a high pressure washer. Don’t wash directly on to electrical con-

tacts.

The compactor has a number of greasing points, that need to be lubricated manually. These points has to be

greased minimum every . See overview in chapter 5.4.4

PE 120 V

3

Loading...

Loading...