12

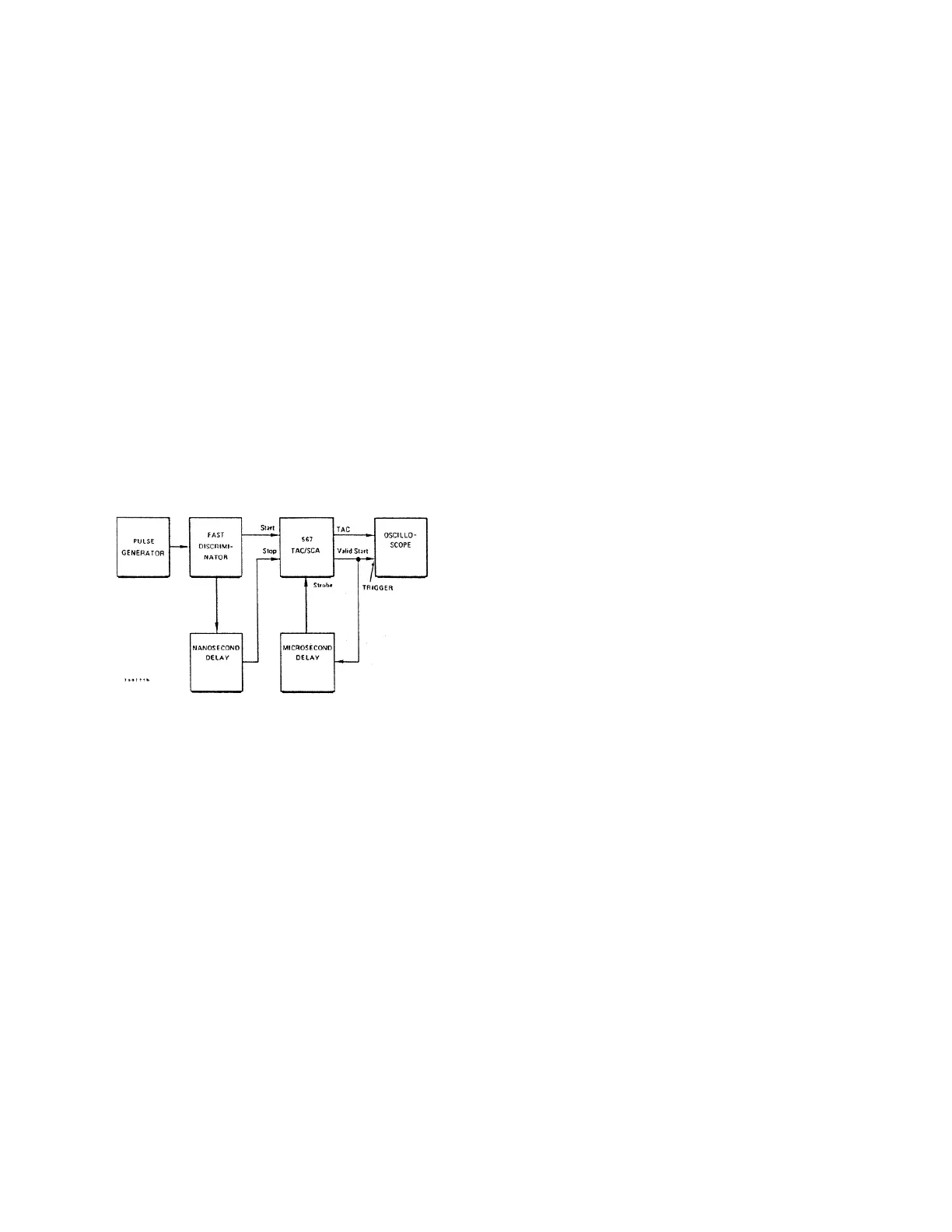

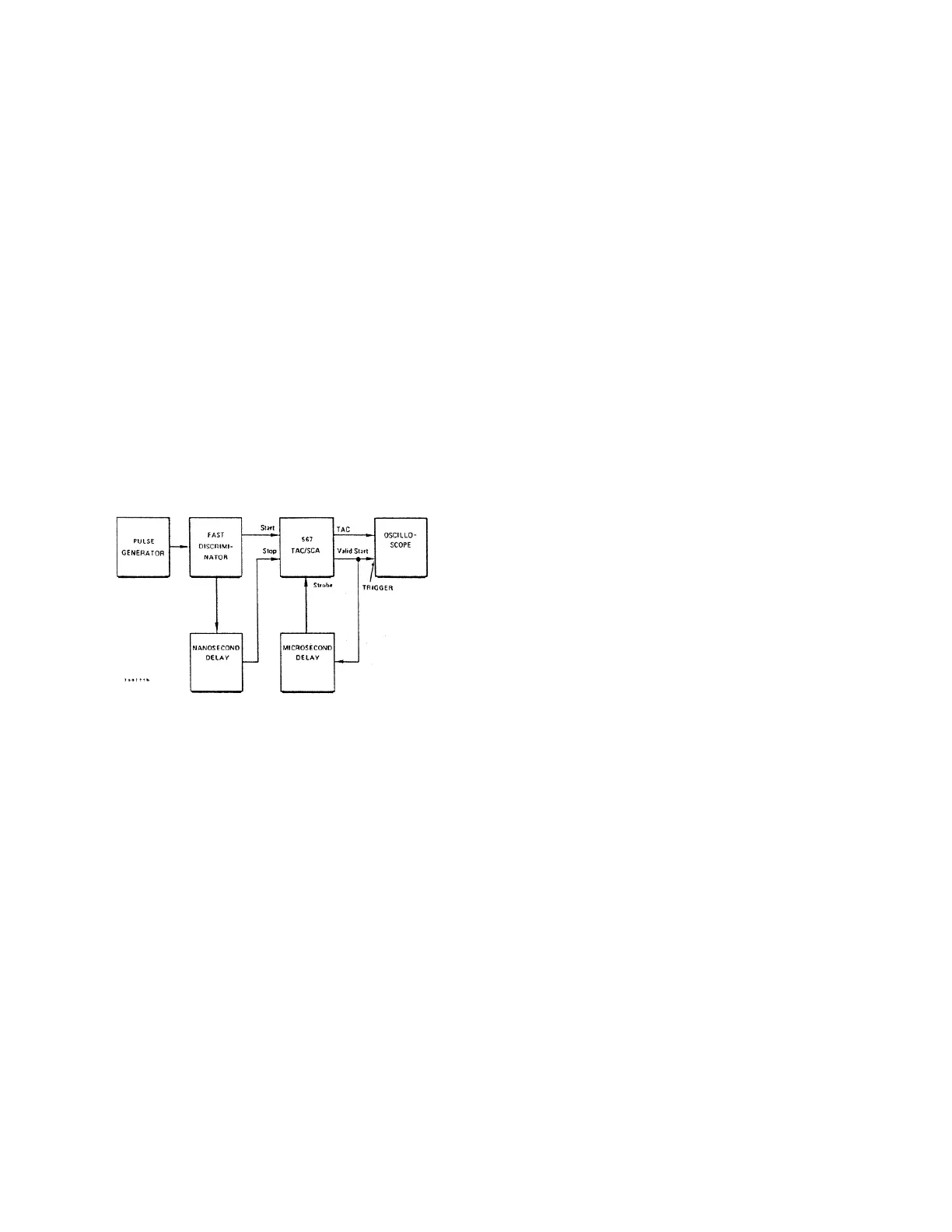

Fig. 7. Test System for Checking External Strobing Mode.

CALIBRATION

Three critical calibrations that may

need to be made are described:

Output Offset Calibration

Potentiometer R223,

located on the printed wiring board (PWB), adjusts

the dc offset voltage of the TAC output over a ±85

mV range. To calibrate the output offset, connect

power to the 567 with no input signal connections.

While monitoring the dc voltage at the TAC output,

adjust R223 to obtain 0 V dc.

Conversion Current Calibration

This calibration

affects the conversion gain of the TAC circuitry. To

calibrate the conversion gain of the 567, set up the

circuit as shown in Fig. 2, and follow the setup

procedures outlined in steps 1 through 3 of

Section 5.1, “Conversion Tests.”

1. Adjust PWB-mounted potentiometer R128 fully

counterclockwise. A TAC output pulse of ~8.5 to

9.8V should be present at the TAC output.

2. Adjust R128 clockwise until the output pulse

reaches +10V and begins to half-fire.

3. Turn R128 slightly in the counterclockwise

direction until the TAC output is solid or full-firing.

Output Width Adjustment

Leave the system

connected as described above. TAC output pulse

width may be adjusted over a range of 1 to 3 µs via

PWB-mounted potentiometer R163. Factory-

adjusted width is nominally 2 µs.

5.3. FACTORY REPAIR

This instrument can be returned to the ORTEC

factory for service and repair at a nominal cost. Our

standard procedure for repair ensures the same

quality control and checkout that are used for a new

instrument. Always contact the Customer Service

Department at ORTEC, (865) 483-2231, before

sending in an instrument for repair to obtain

shipping instructions and so that the required

Return Authorization Number can be assigned to

the unit. Write this number on the address label and

on the package to ensure prompt attention when it

reaches the ORTEC factory.

Loading...

Loading...