Microstat He Manual

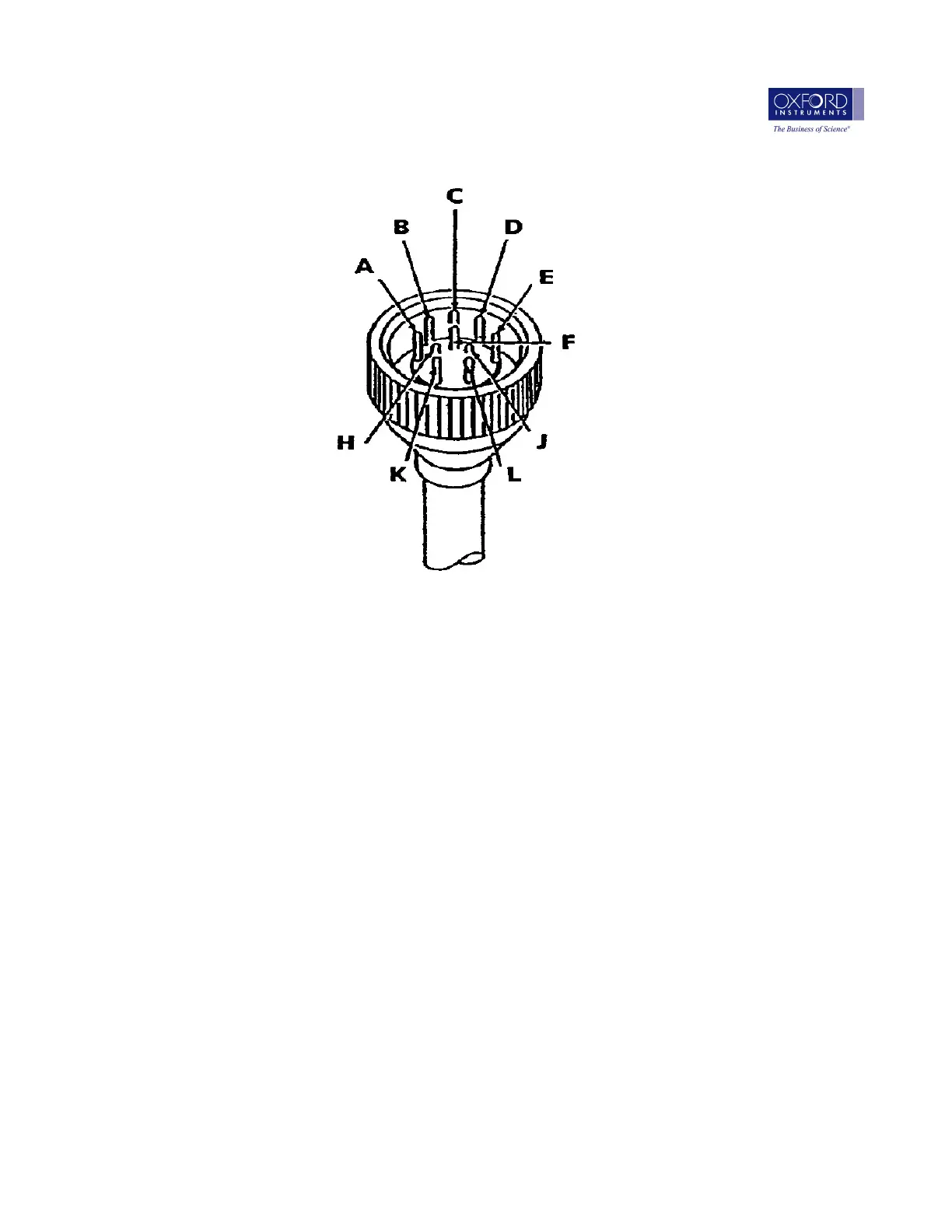

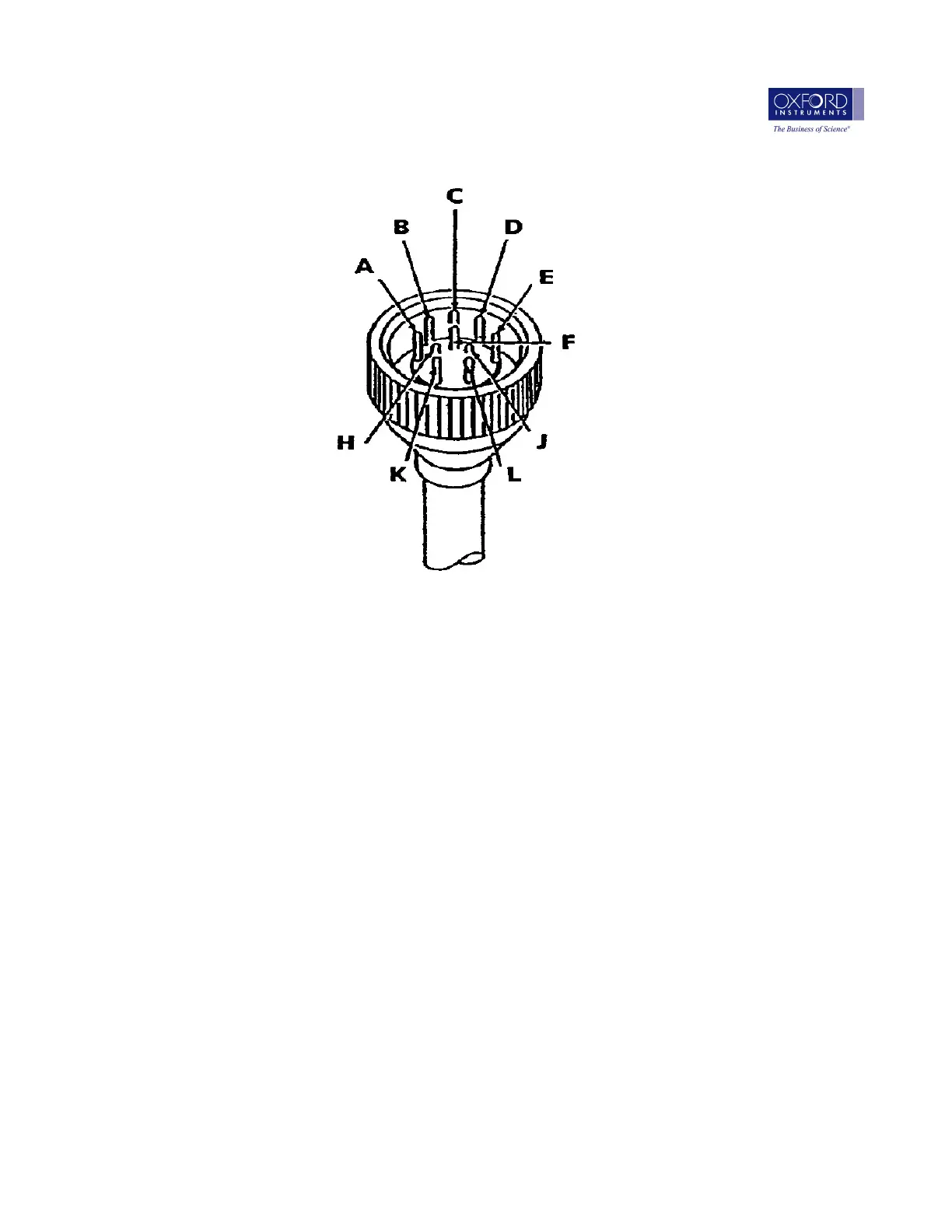

Figure 9.1: Ten-pin seal configuration

Any wiring made to the sample should be thermally anchored to the heat exchanger or sample holder in order to reduce the heat load on

the sample.

9.2 Troubleshooting

The following list summarises the most common faults on the system. You may also need to refer to the troubleshooting guide in the

transfer siphon manual.

Cryostat OVC cannot be pumped to high vacuum OR Water condenses on the cryostat body when it is cold

Check the cryostat OVC for leaks. In particular check the top plate seals and outer window seals.

If there is no leak there may be too much moisture in the OVC and it should be pumped with a rotary pump, with the gas ballast valve

open.

Cryostat will not cool down

Check whether there is any flow of gas through the system, using the gauge on the VC-U if applicable.

Poor temperature stability

Check that the PID settings on the temperature controller and the cryogen flow rate are as suggested in the manual and test results.

Cryostat cannot be warmed up from base temperature OR Heater not working

Check that the set temperature is higher than the present sample temperature, or switch the heater on manually.

© 2017 Oxford Instruments Nanoscience MAN-MHE-1.1.0 (28ff3d8) Sep 2017 34

Loading...

Loading...