4 START UP & ROUTINE

CHECKS

4.1 START UP

Before starting the pump for the first time or after

servicing or maintenance work, check the

following - failure to do so could damage

equipment or cause injury to personnel.

• Pump and pipes are clear of welding flash

or other debris.

• All pump head and mounting bolts are

tight.

• All pipe connections are secure

• All guards, safety and protection devices,

are in place and effective.

• Check the motor is wired for the correct

direction of rotation (Figure 16 and Table

3 - Direction of flow)

• Flushing fluid, if required, is flowing.

(See 3.11 SEALS AND FLUSHING )

ATTENTION

Do not use HP or LH pumps to flush the system

the first time. Flush the whole system with

suitable cleaning agents before starting the pump,

using another more suitable pump if necessary.

Be aware that heavy or metal debris tends to

collect at the lowest point in the system.

• All valves are open - NEVER run the

pump against a closed valve.

• Pipes and pump head, if heated, are to

normal operating temperature.

• Pump is correctly lubricated.

(See 3.14 LUBRICATION)

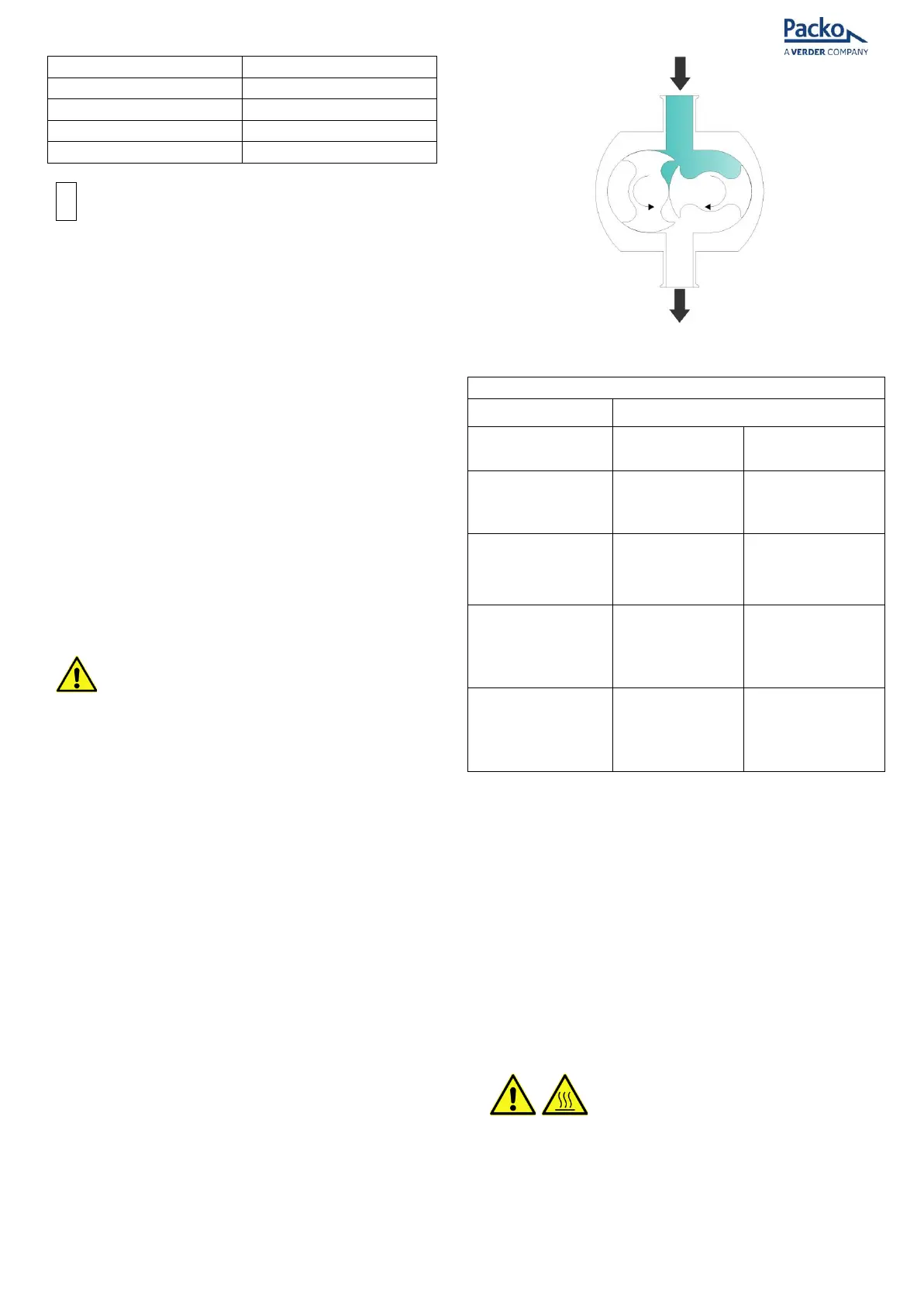

Figure 16 - Direction of rotation - viewed from pump

head (Principle applies to all mounting orientations)

Table 3 - Direction of flow

When possible, start the pump slowly and

increase speed gradually.

• Listen for unexpected noises.

• Check for leaks.

• Check that the pump gives the desired

flow rate, using the pumped media at

normal operating speed.

• Do not continue to run the pump if the

fluid is not flowing; dry running can

damage seals.

(See 3.11 SEALS AND FLUSHING)

ATTENTION

• Observe the pump during the first few

hours of operation - check for noises and

excessive heating of pump, e.g. if above

80°C (176°F), unless pumping hot liquids

Loading...

Loading...