Safety and Information Symbols

S

afety and information is identified in this instruction manual with the following symbols:

Warning! Identifies a dangerous situation where there is a safety risk and personal injury may follow.

I

mportant: Identifies a potentially dangerous situation, a risk to the equipment or other important

information.

Note: Identifies user tips and other useful information.

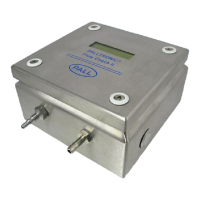

1. Safety Instructions

Warning! Please read the following instructions carefully and completely before using the

Palltronic Flow Check II unit.

Please also read the Operating Instructions for the applicable integrity test instrument which will

be used with the Palltronic Flow Check II unit to ensure safe use. The list of literature is as follows:

Table 1

Literature

Document Title Number

Palltronic Flowstar IV Integrity Test Instrument: Instructions for Use USD2594

Palltronic Flowstar XC Integrity Test Instrument: Operating Instructions USD2005

Palltronic Flowmod Filter Integrity Test Instrument: Operating Instructions USD2223

Palltronic Flowstar MUX Integrity Test System: Operating Instructions USD2292

Palltronic AquaWIT XC Automatic Integrity Test System: Operating Instructions USD2363

Please contact your local Pall office or distributor if you require a copy of the latest revision of

any of these documents.

1.1 Personal Safety

• Appropriate protective clothing should be worn by operators (e.g., gloves and safety goggles)

when working with chemicals and compressed gas supplies during filter integrity testing.

• All pneumatic tubing used for integrity testing and with the Palltronic Flow Check II unit should

be rated to withstand the gas pressure used (up to 8 bar or 116 psi).

• The operator should check the tubing and connectors for damage before each use.

1.2 Safe Use of the Palltronic Flow Check II Unit

• The Palltronic integrity test instrument uses compressed air when in use and, therefore, caution

is necessary when disconnecting pneumatic connections from the Palltronic Flow Check II unit.

It is the user’s responsibility to ensure that an oil-free regulated gas supply is used during

operation of the Palltronic integrity test instrument and Palltronic Flow Check II unit.

• The maximum operating pressure of the Palltronic Flow Check II unit is 3.0 bar (43.5 psi) at a

maximum operating temperature of 40 °C.

• Do not exceed the maximum operating pressure.

• Compressed gas exits the Palltronic Flow Check II unit at low velocity through the ‘VENT’

port. To ensure correct and safe operation, the ‘VENT’ port must be open to atmosphere.

www.pall.com/biopharm 3

Loading...

Loading...