27

3-4. Prepare the Tubing

● Material: Use seamless phosphorous deoxidized copper

tube for refrigeration. Wall thickness shall comply with the

applicable legislation. The minimal wall thickness must be

in accordance with the table below. For tubes of ø22.22 or

larger, use the material of temper 1/2H or H (Hard copper

tube). Do not bend the hard copper tube.

● Tubing size

Use the tubing size indicated in the table below.

● When cutting the tubing, use a tube cutter, and be sure to

remove any burrs.

The same applies to distribution tubing (optional).

● When bending the tubes, bend each tube using a radius

that is at least 4 times the outer diameter of the tube. When

bending, use sufficient care to avoid crushing or damaging

the tube.

● For flaring, use a flare tool, and be sure that flaring is

performed correctly.

CAUTION

Use sufficient caution during preparation of the tubing.

Seal the tube ends by means of caps or taping to prevent

dust, moisture, or other foreign substances from entering

the tubes.

Refrigerant tubing

Tubing size (mm)

Material Temper - O

(Soft copper tube)

Material Temper - 1/2 H, H

(Hard copper tube)

Outer dia. Thickness Outer dia. Thickness

ø6.35 t0.8 ø22.22 t1.0

ø9.52 t0.8 ø25.4 t1.0

ø12.7 t0.8 ø28.58 t1.0

ø15.88 t1.0 ø31.75 t1.1

ø19.05 t1.2 ø38.1 over t1.35

ø41.28 over t1.45

3-5. Connect the Tubing

● When operating the refrigerant tube installation in the

field, do not apply the flame of welding to the surrounding

sheet-metal parts. If necessary, use a wet rag to prevent

overheating of the heat exchanger.

● Use the supplied connector tubing.

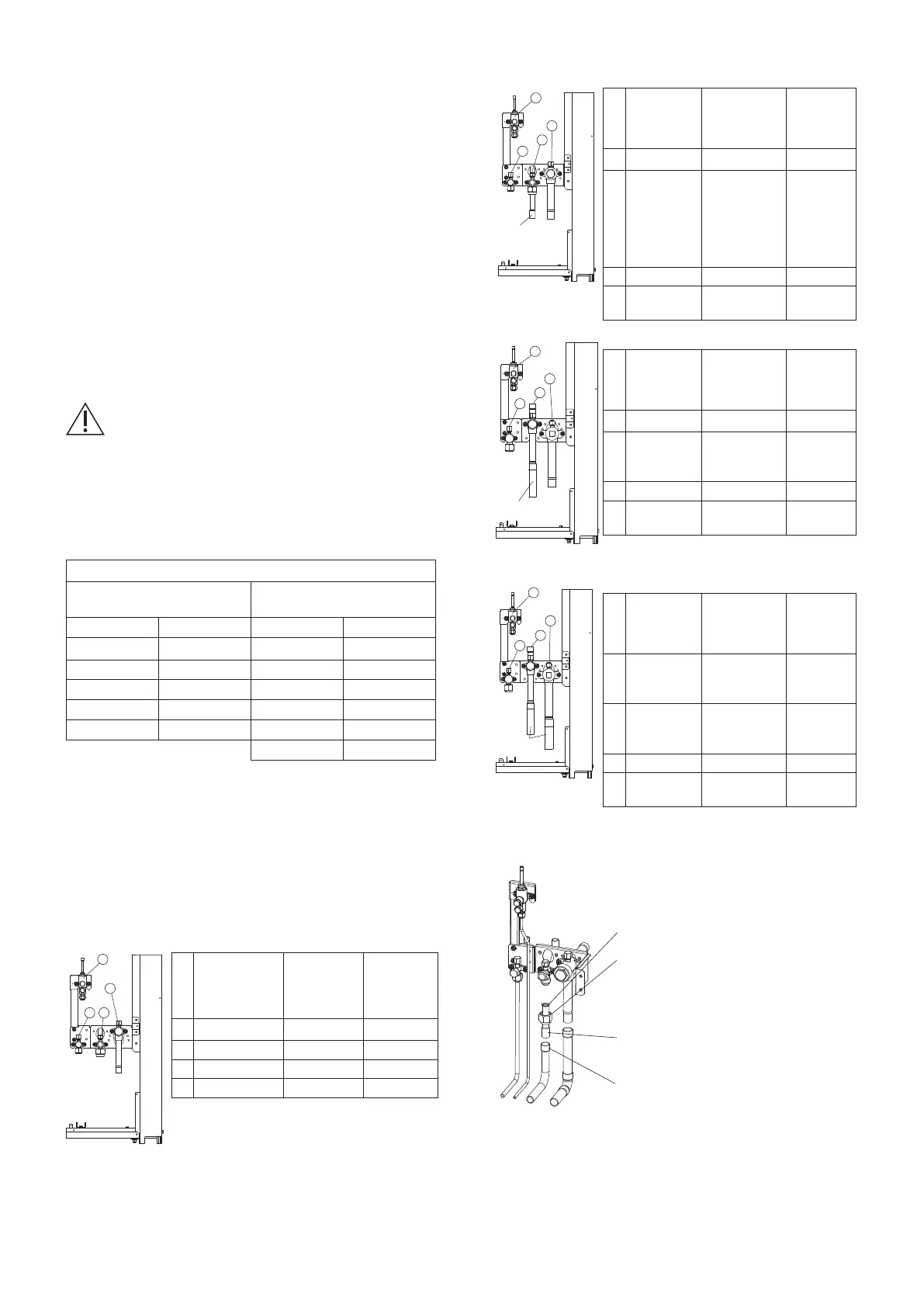

1

2

3

4

10/12 HP

Supplied

tube

1

2

3

4

14 HP

16 HP

Supplied

tube

1

2

3

4

Supplied tube

1

2

3

4

Refrigerant

tubing

Connection

method

Use

Supplied

connector

tube?

1

Suction tube Brazing No

2

Discharge tube Flare No

3

Liquid tube Flare No

4

Balance tube Flare No

Refrigerant

tubing

Connection

method

Use

Supplied

connector

tube?

1

Suction tube Brazing No

2

Discharge

tube

Service valve

mounted on the

unit side: Flare

connection

Tubing side:

Brazing

Yes

ø15.88

Flare

↓

ø19.05

Brazing

3

Liquid tube Flare No

4

Balance

tube

Flare No

Refrigerant

tubing

Connection

method

Use

Supplied

connector

tube?

1

Suction tube Brazing No

2

Discharge

tube

Brazing

Yes

ø19.05

→ø22.22

3

Liquid tube Flare No

4

Balance

tube

Flare No

Refrigerant

tubing

Connection

method

Use

Supplied

connector

tube?

1

Suction tube Brazing

Yes

ø25.4

→ø28.58

2

Discharge

tube

Brazing

Yes

ø19.05

→ø22.22

3

Liquid tube Flare No

4

Balance

tube

Flare No

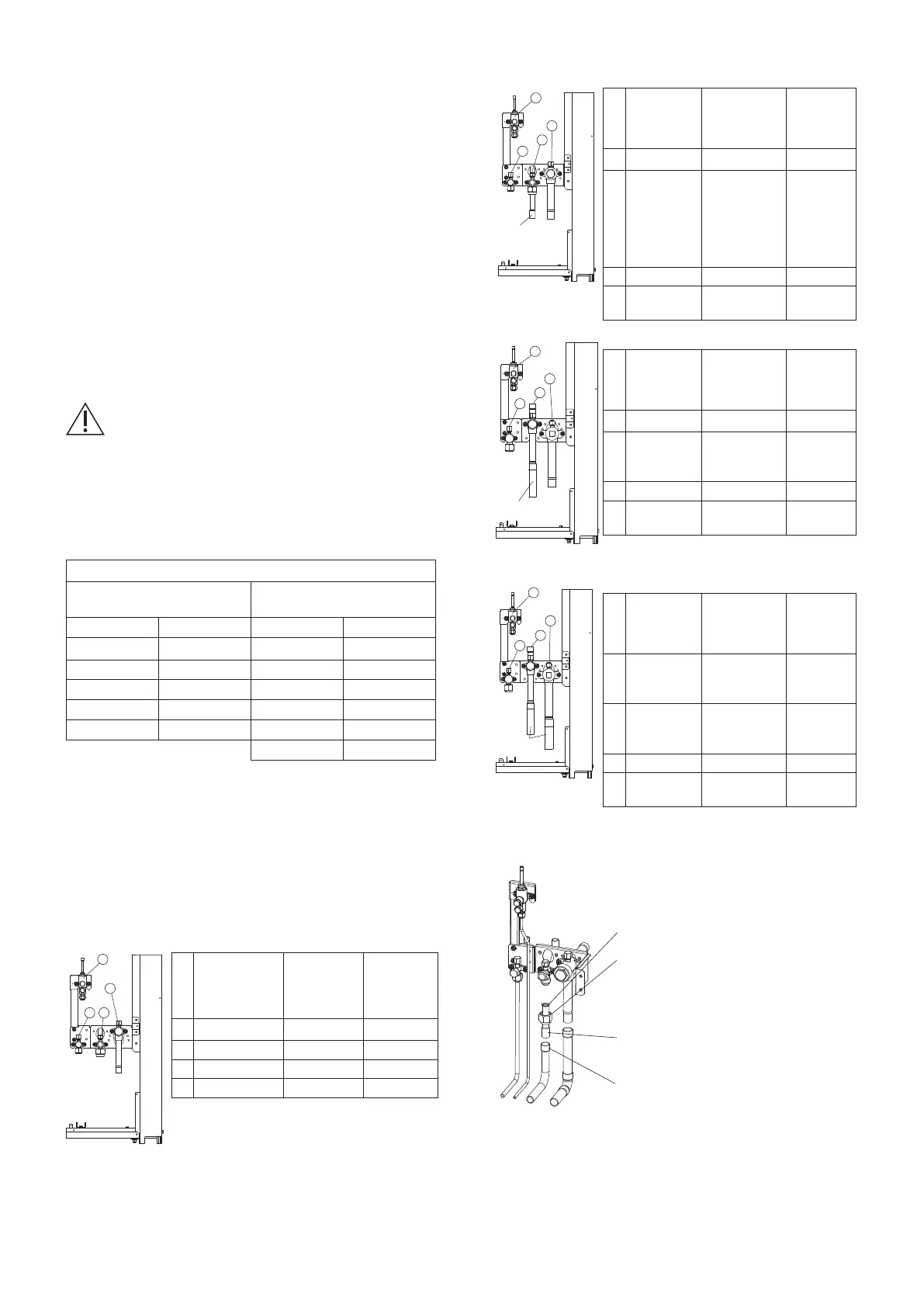

8 HP

Unit: mm

Unit: mm

Unit: mm

10/12 HP

Supplied

tube

1

2

3

4

14 HP

16 HP

Supplied

tube

In case of 10/12 HP

Flaring process to the tip of the

supplied tubes

Use the wide area of the outer tubing

surface of the supplied tubes.

•

Supplied tubing outer diameter ø19.05

•

Local tubing inner diameter ø19.05

Remove flare nuts attached to the service

valve and reuse them.

Note: Make sure the service valve is

completely closed.

If not, the gas leak will be occurred.

00_341136_2WAY_Eng.indb 27 2022/9/19 9:27:25

Loading...

Loading...