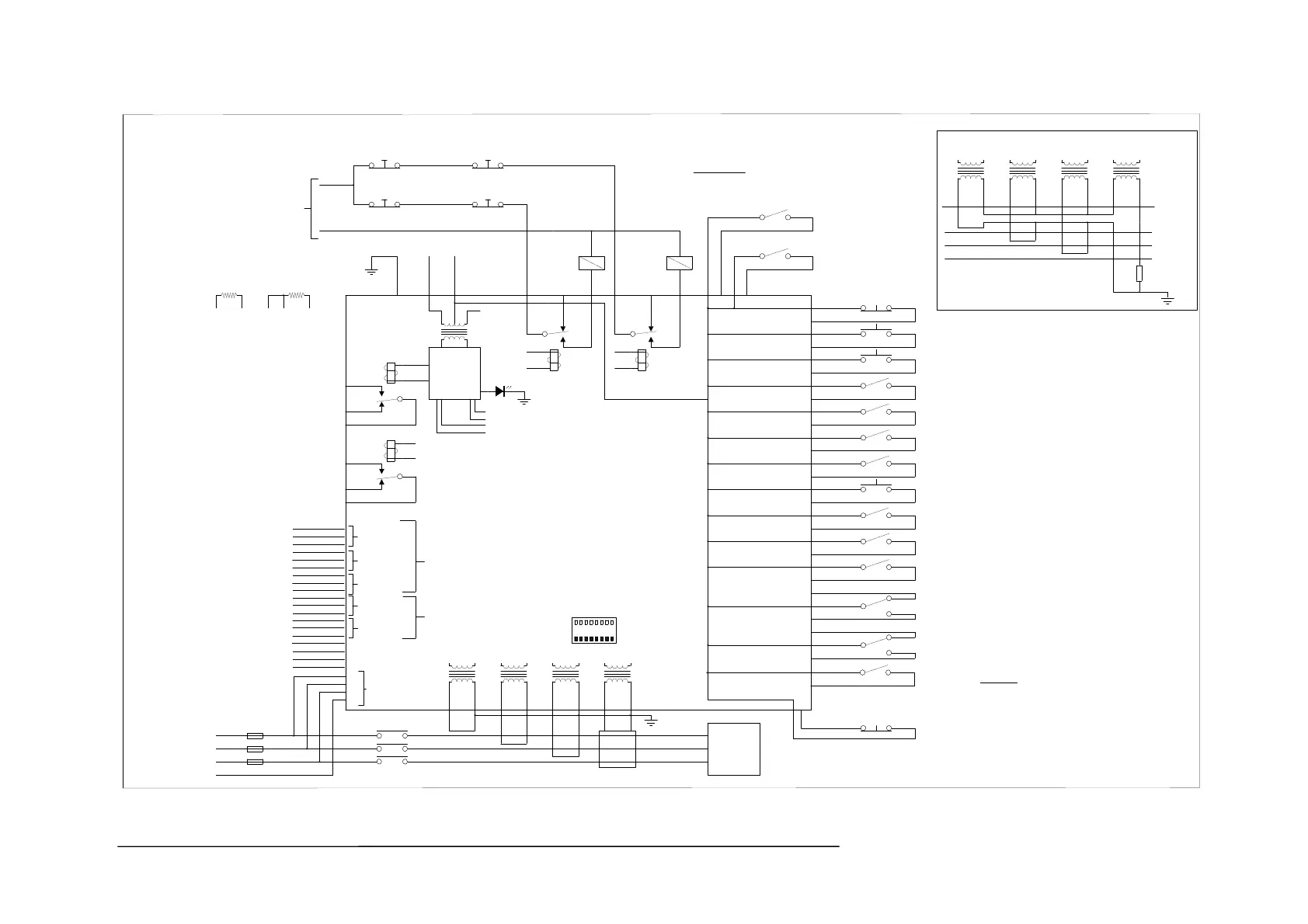

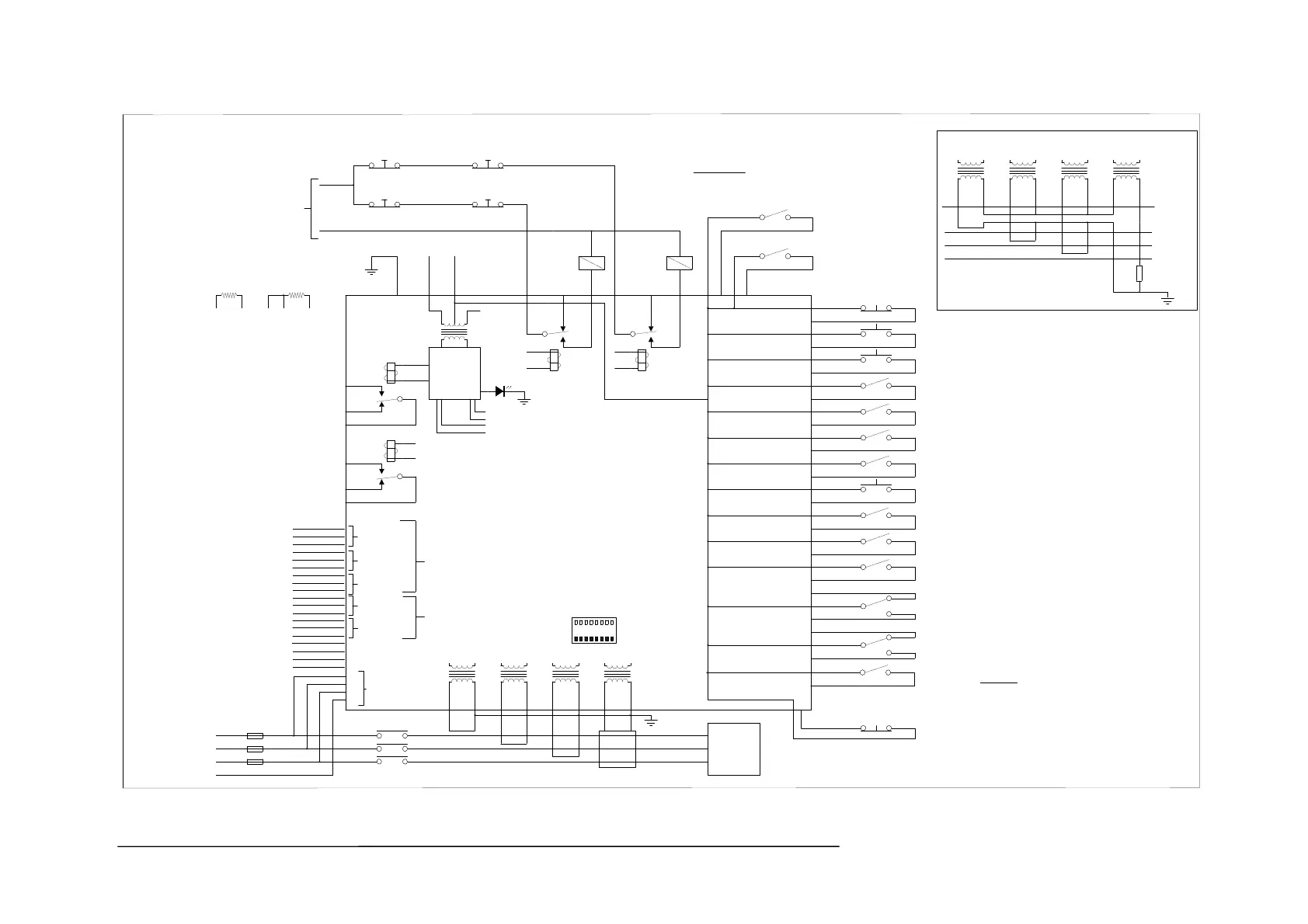

MPC2000D Issue 2 22/4/98 Page 7

N

5 7 9 6 8 10

64

63

66

65

68

67

58

57

74

73

72

71

29

30

70

69

60

59

62

61

3

4

83

82 84

81

79

78 80

77

75

76

32

L1

L2

L3

N

(Not always available)

13

15

14

16 N

L3

L2

L1

37

35

33

38

36

34

MPC2000D WIRING DIAGRAM

MPC2000D

39

42

45

40

43

46

41

44

47

39

42

45

40

43

46

12CASE

31

CT4CT3CT2CT1

21 22 23 24 25 26 27 28

17 18 2019

NOTE:

RELAY SUPPLIED AS 1 AMP OR

5 AMP AS REQUIRED

SWAMPING

RESISTOR

STOP [NC]

START CONTACTOR A [NO]

START CONTACTOR B [NO]

PLANT INTERLOCK [OPEN=LOCKED OUT]

LOCAL/REMOTE [OPEN=LOCAL]

PLC/SERIAL PORT [OPEN=PLC]

AUTHORISED KEY [CLOSED=AUTHORISED]

PLC RESET [NO]

PLC CONTROL A [OPEN=STOP]

PLC CONTROL B [OPEN=STOP]

SPEED SWITCH [OPEN=HIGH]

CONTACTOR A STATUS

CONTACTOR B STATUS

ISOLATOR

EXTERNAL EMERGENCY STOP [NC]

ALTERNATIVE RESIDUAL FAULT CONNECTION

EXTERNAL FAULT 3

EXTERNAL FAULT 2

OR SYSTEM TEST

[SET BY DIP SWITCH 1]

DIP SWITCH 1

ON = TEST FACILITY AVAILABLE

OFF = EXTERNAL FAULT 3

CONTACTOR BCONTACTOR A

STOP B

STOP A

AUX. SUPPLY

INTERNAL

POWER

SUPPLY

ON

LOGIC SUPPLY

ALT. AUX POWER SUPPLY

CT1

CT2

CT3

CT4

MOTOR

MEASURMENT

VOLTAGES

AUX 2 RELAY [TRIP]

AUX 1 RELAY [ALARM]

GND

THERMISTOR

[0.1K-30K]

PT100

[100-2400]

MAIN CONTACTOR

CONTROL

VOLTAGE

STOP B

STOP A

CONTACT SHOWN IN

DE-ENERGISED STATE

21 22 23 24 25 26 27 28

39

40

41

42

43

44

45

46

47

48

49

50

55

56

54

(-)

(+)

3 RTD OR 3 THERMISTORS

DIP SWITCH SETTINGS

ON [THERMISTOR]

OFF [RTD]

RS485 SERIAL PORT

SHIELD

CHANNEL 1

CHANNEL 3

CHANNEL 2

51

52

53

CHANNEL 5

CHANNEL 4

SCREEN

11,12

OPTIONAL 2 RTD INPUTS

FOR CHANNELS 1,2&3

NOTE TERMINALS 11,12

& 54 ARE INTERNALLY

CONNECTED.

FOR SEPERATE INSTRUMENT

EARTHING TERMINAL 11

MUST BE CONNECTED TO

A SEPERATE EARTH FROM

THE CASE.

OTHERWISE CONNECT TO

THE CASE. (SEE SECTION 4.0)

Loading...

Loading...