21GB

U

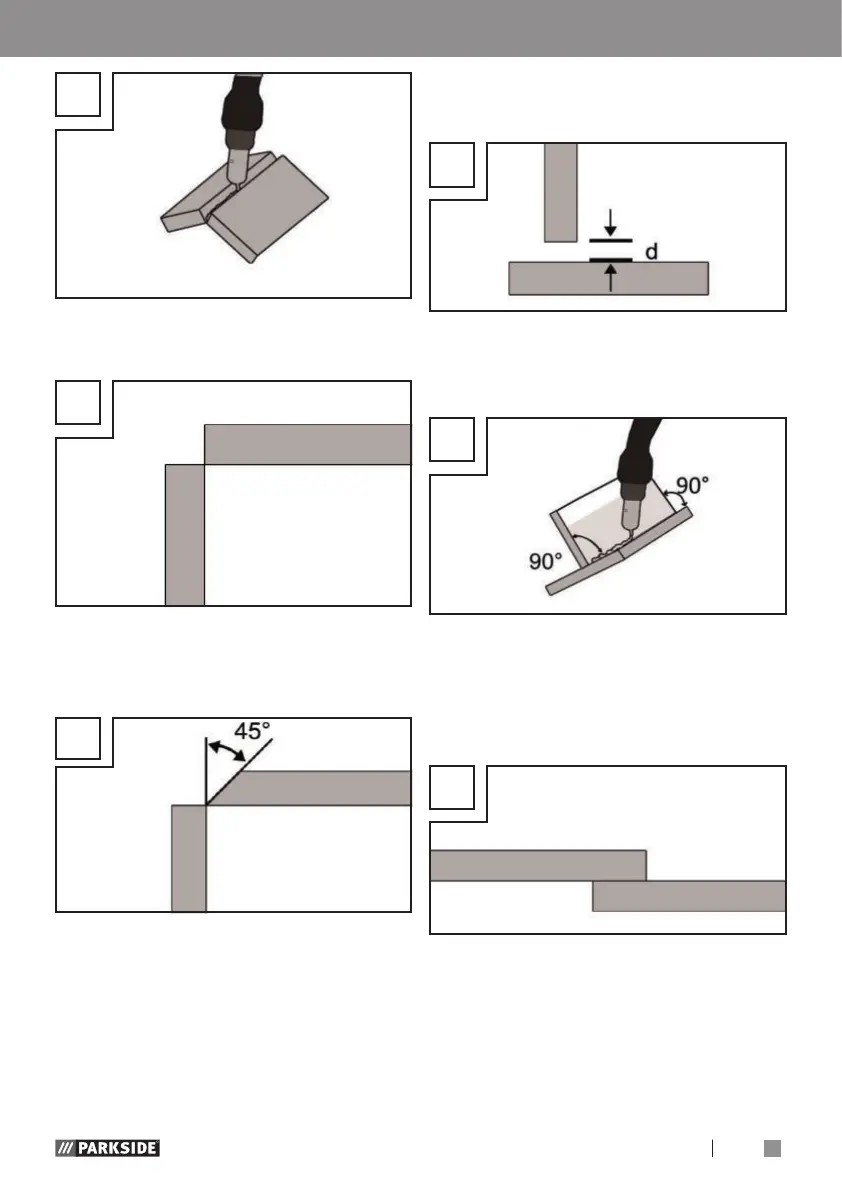

Welds on the outer edge

The preparation for this is very simple.

V

However, it is no longer expedient for thicker

materials. In this case, it is better to prepare

a joint as shown below, in which the edge of

the plate is angled.

W

Fillet weld connections

A fillet weld is created if the workpieces are

perpendicular to each other. The weld should be

shaped like a triangle with sides of equal length

and a slight fillet.

Welds on an inner corner

The preparation for this weld joint is very simply

and is carried out for thicknesses of 5 mm.

The dimension “d” needs to be reduced to a

minimum and should always be less than 2

mm.

X

However, it is no longer expedient for thicker

materials. In this case, it is better to prepare

a joint as shown in Figure W, in which the

edge of the plate is angled.

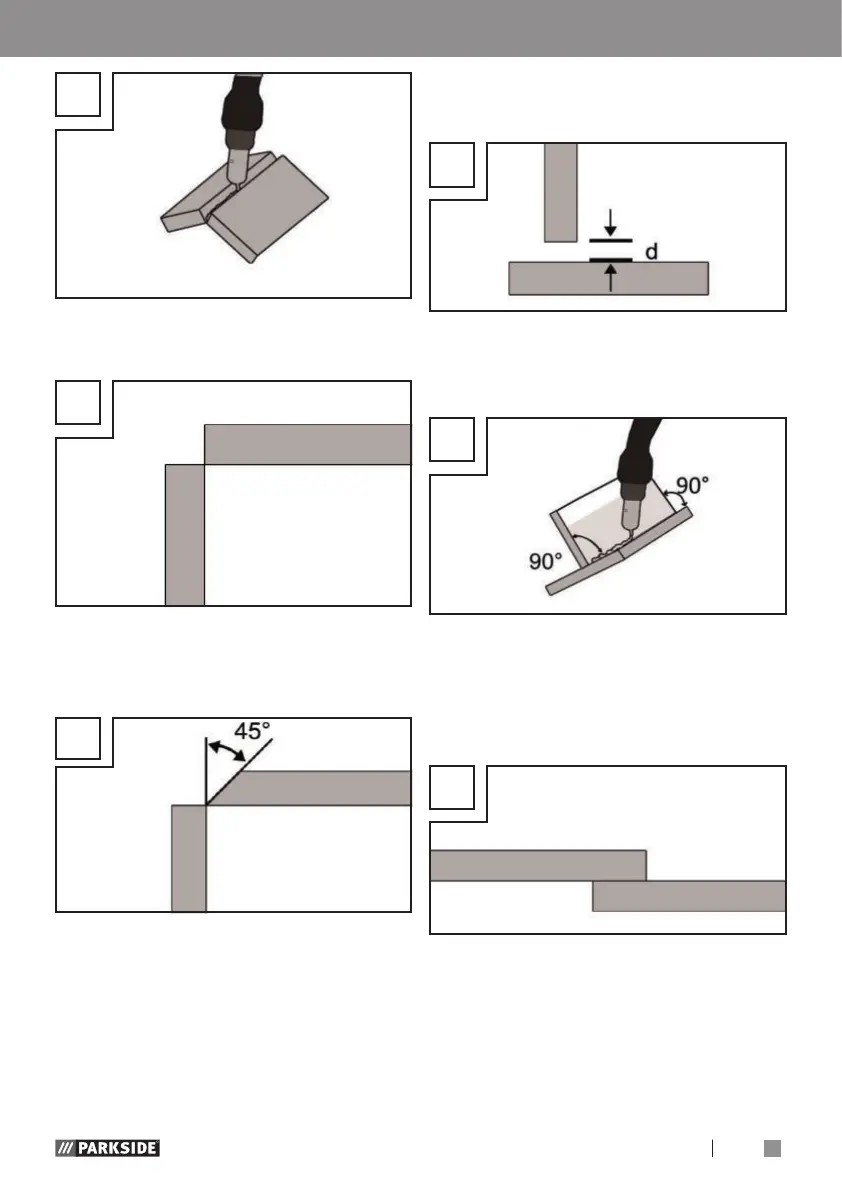

Y

Overlap welds

The most common preparation is that with

the straight weld edges. The weld can be

released using a standard angle weld. Both

workpieces must be brought as close to each

other as possible.

Z

z Maintenance and cleaning

Note: The welding device must be regularly

serviced and overhauled for proper function

and for compliance with the safety require-

ments. Improper and wrong operation may

cause failures and damage to the device.

Commissioning / Maintenance and cleaning

Loading...

Loading...