GB/IE/NI/CY/MT 11

3. Compressor operation

3.1 Before first use

Remove all packing material and transport locks from the device. Check that

the package contents are complete and undamaged. If possible, keep the

packaging until the warranty period has expired.

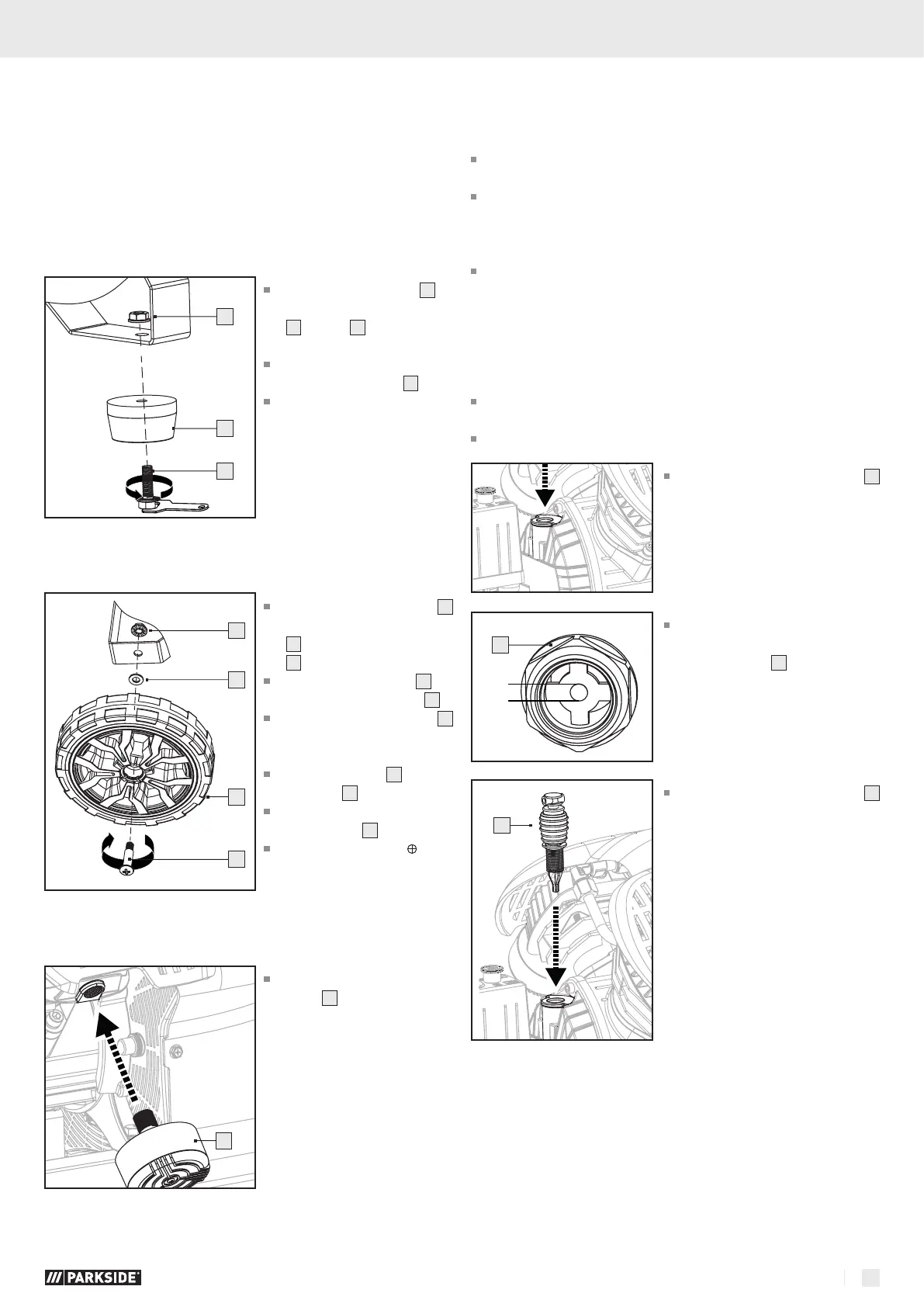

3.1.1 Mounting the support stands

20

8

19

Mount the support stand

8

us-

ing the hexagonal head screw

19

and nut

20

as shown in the

illustration.

Repeat these steps to mount the

second support stand

8

.

An open-end spanner is not in-

cluded in the scope of delivery.

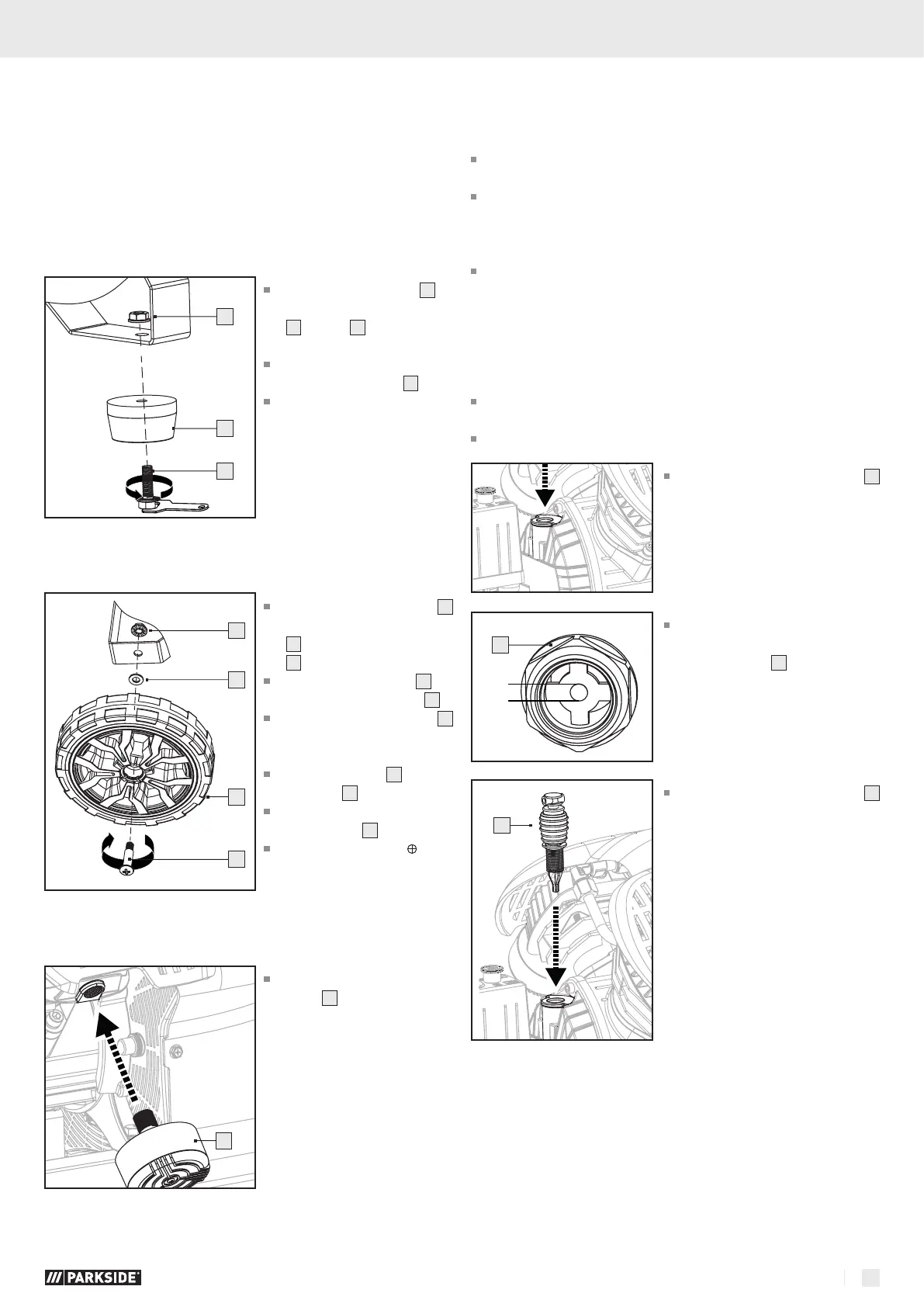

3.1.2 Mounting the wheels

18

17

6

16

Insert the Phillips screw

16

through the hole in the wheel

6

and then into the washer

17

.

Make sure that the wheel

6

can

still be turned on the screw

16

.

Pass the Phillips screw

16

through the hole on the wheel

linkage.

Fasten the wheel

6

with the

flange nut

18

.

Repeat these steps to mount the

second wheel

6

.

An open-end spanner is not

included in the scope of deliv-

ery.

3.1.3 Fitting the air filter

4

Screw

the two supplied air

filters

4

onto the unit until

hand-tight.

3.1.4 Setting up the device

For safe and correct operation of the device, the installation site must meet the

following requirements:

The floor must be firm, flat and level. Do not place the device in a hot, wet

or very humid environment or near combustible material.

The socket must be easily accessible so that the mains plug can be easily

disconnected if necessary. The use of a cable extension is not recommend-

ed. Long supply cables can cause a voltage drop and thus prevent the

motor from starting.

If you still have to use a cable extension, make sure that it is not longer than

5 m and that the cross-section is at least 1.5 mm². ALWAYS use the cable

extension rolled out!

3.1.5 Filling the compressor with oil

During initial operation, the compressor pump housing must be filled with

oil.

Remove the oil filler opening transport cover.

Fill the supplied compressor oil

21

into the compressor pump housing.

15

min.

max.

The oil level must lie between the

max. and min. marks on the oil

level indicator

15

.

3

Now insert the oil sealing plug

3

firmly into the oil filler opening.

ATTENTION!

Check the oil level before each start-up!

Loading...

Loading...