How to fix Paslode F250S-PP when fasteners will not drive completely into wood?

- MMary BarnesJul 28, 2025

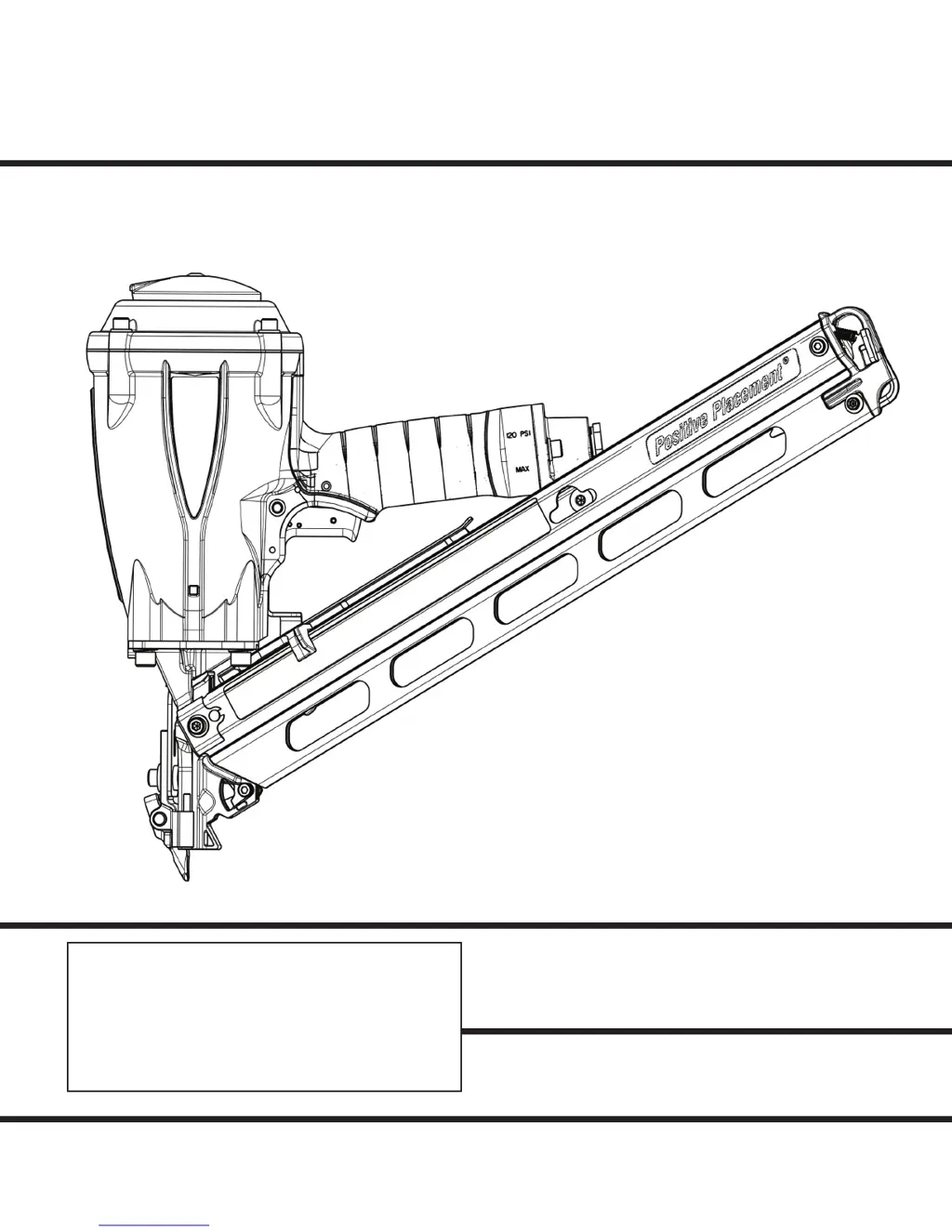

To fix fasteners that won't drive completely into the wood when using Paslode Tools, adjust the work contacting element by retracting its length and increase the air pressure, but do not exceed 120 psi.