A. GENERAL

1. The disposal of all condensate into public sewage

systems is to be in accordance with local codes and

regulations. In the absence of such codes, follow these

instructions.

2. Proper piping and removal of condensation from

combustion is critical to the operation of a condensing

appliance. Follow these instructions carefully to assure

that your P

UREFIRE boiler operates correctly.

3. Depending on several factors, the condensate from

gas fired condensing appliances may have a pH value

as low as 2.5 (similar to cola soft drinks). Some local

codes require the use of neutralization equipment to

treat acidic condensate.

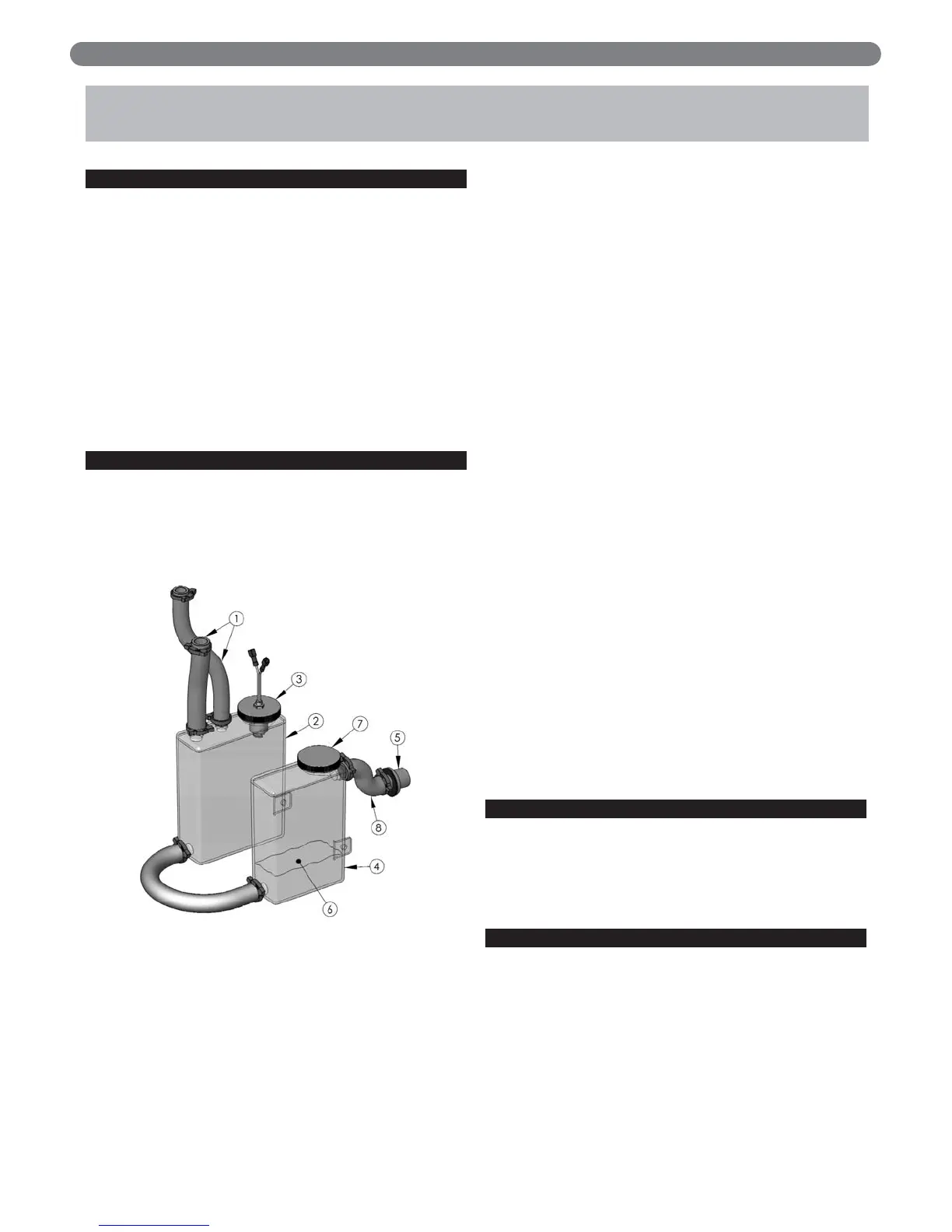

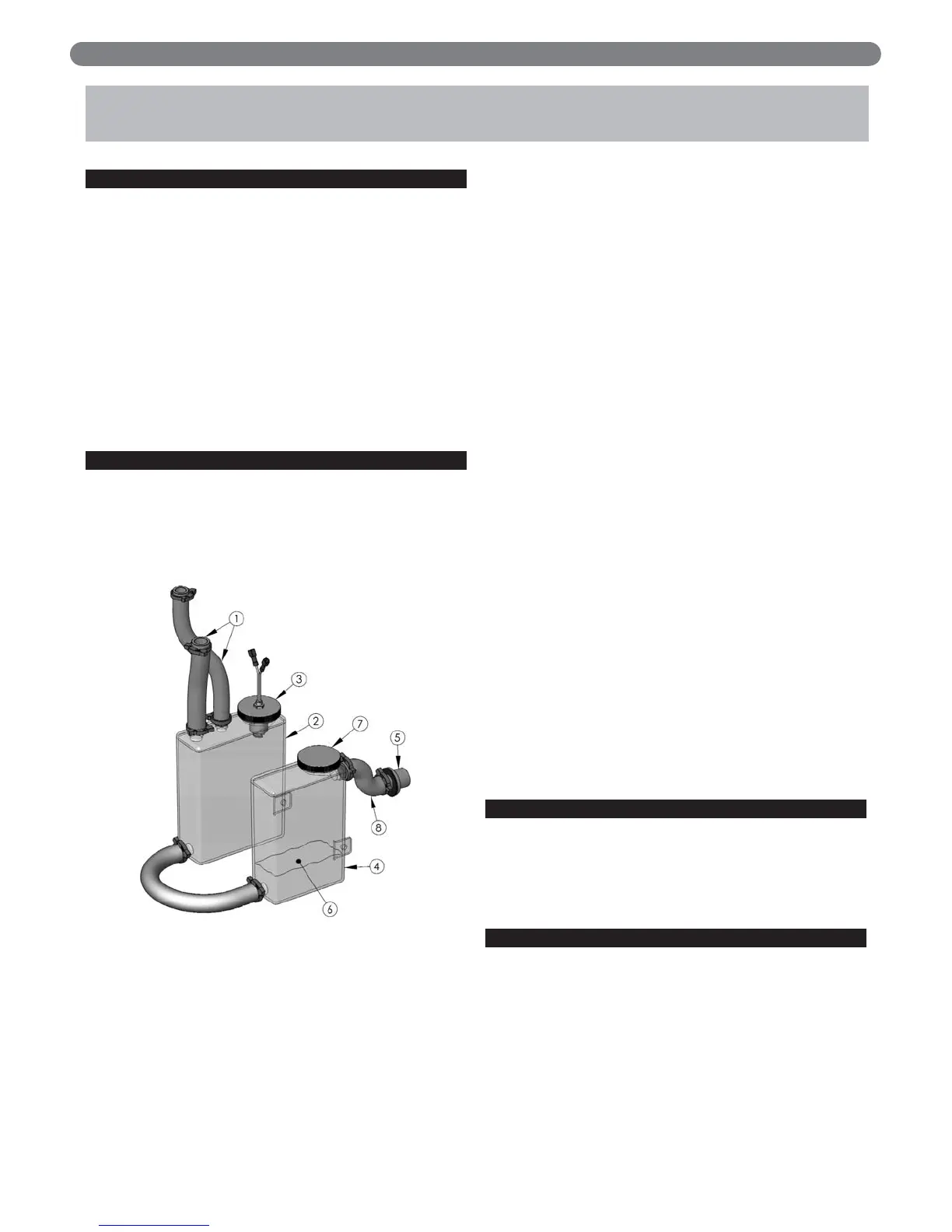

B. CONDENSATE SYSTEM

The PUREFIRE condensate system is designed to prevent

condensate from backing up into the heat exchanger, trap

the condensate to prevent combustion gases from

escaping and neutralize acidic condensate. Refer to Figure

6.1 for an illustration of the system components.

1. Condensate Drain Hoses: There are two condensate

drain hoses attached to the heat exchanger. The first

drains condensate from the combustion chamber of

the boiler. The second drains condensate from the

vent system. This prevents dirt and debris from the

venting system from entering the heat exchanger and

fouling the heating surface.

2. Condensate Collector Container: The condensate

collector container is a transparent container in the

base of the boiler near the back. This container

collects the condensate and acts as a part of a trap to

prevent combustion gases from escaping. The

container is fitted with a level switch that will prevent

the boiler from operating if the condensate line is

clogged.

3. Condensate Float Switch: This switch will prevent the

boiler from operating if the condensate outlet is

clogged before the level of condensate reaches the

heat exchanger.

4. Condensate Neutralizer Container: The condensate

neutralizer container is an additional transparent

container near the front of the boiler. Fill this

container with the condensate neutralizer provided.

The neutralizer will be consumed during normal

operation and should be checked occasionally to

determine if additional neutralizer is necessary.

Neutralizer is available in 1 lb bags (#54159) from

your PB Heat Distributor.

5. Bulkhead fitting: The bulkhead fitting allows the

condensate tubing to pass through the jacket without

providing a path for leakage from the jacket. A PVC

TEE is to be attached to the outlet of this fitting to

prevent siphoning of the trap.

6. Neutralizer: Condensate neutralizer is provided in a

package with the boiler to fill the condensate

neutralizer container (Item 4).

7. Neutralizer Cap: This cap provides access for adding

and inspecting the condensate neutralizer.

8. Condensate Drain Tube: This pre-formed tube

connects the condensate system to the bulkhead

fitting for attachment to an external drain.

C. CONDENSATE DRAIN PIPE MATERIAL

The condensate drain is to be piped using PVC,

polypropylene, or other material resistant to acidic

condensate. Do not use steel, brass or galvanized pipe for

this purpose. The acidic condensate will attack most

metals and corrode.

D. CONDENSATE DRAIN PIPE SIZING

The bulkhead fitting for condensate connection is for 3/4"

schedule 40 PVC Pipe. Be sure to use 3/4" or larger

tubing from the boiler to the drain.

24

CONDENSATE DRAIN PIPING

6. CONDENSATE DRAIN PIPING

Figure 6.1

Loading...

Loading...