Low-voltage wiring

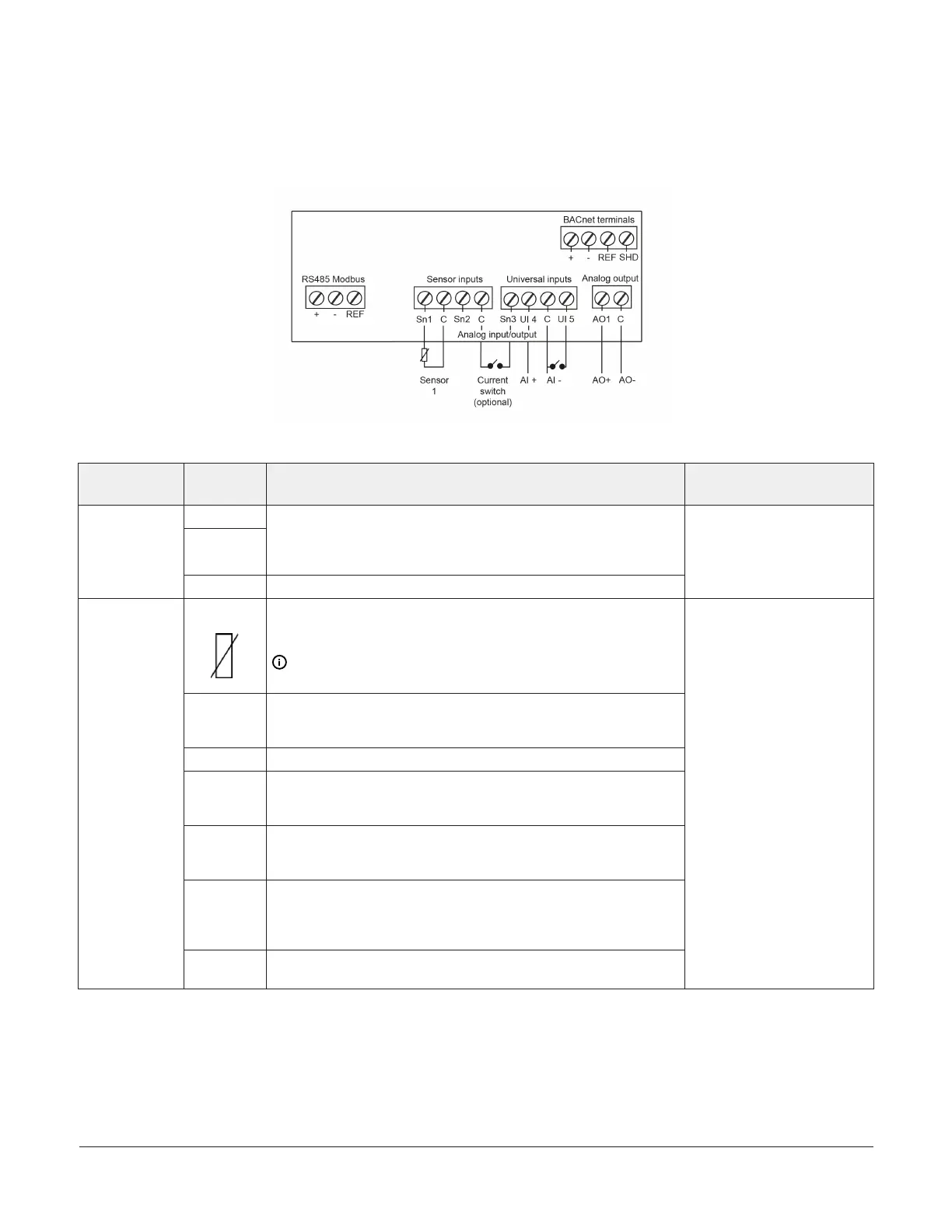

The following figure and table provide information about the low-voltage wiring terminal blocks, wiring terminal labels,

and required wire sizes.

Figure 4: A525 Controller low-voltage terminal block connections (internal to control)

Table 2: A525 Controller low-voltage terminal block, terminals, and wire sizes

Terminal

block label

Terminal

label

Description, function, and requirements Required wire sizes

+

-

The RS485 Modbus communications terminal block is

restricted to an optional variable-frequency drive (VFD) that

is used to control pump-over operations. Do not connect

another Modbus device to these terminals.

RS485

Modbus

REF The RS485 Modbus signal common or reference

• 0.20 mm

2

– 0.30 mm

2

• (26 AWG–22 AWG)

• Stranded wires and

twisted-leads cable

Sn1

Sensor 1 (Sn1) is the main tank temperature sensor. Connect

either lead from the sensor to Sn1. Connect the other lead to

a common (C) terminal.

Note: Sensor wires for the A525 Controller are not

polarity sensitive.

C

The A525 Fermentation Controller includes four low-voltage

common terminals. All of the low-voltage C terminals are

connected together on the PC board.

Sn2 Sensor 2 (Sn2) is unused.

Sn3

You can use Sensor 3 (Sn3) with a current switch. The current

switch monitors the status of the pump motor. This is an

optional feature.

UI 4

You can use Universal Input 4 (UI 4) to monitor the speed of

a pump motor if the VFD provides this output signal to the

control. This is an optional feature.

UI 5

You can use Universal Input 5 (UI 5) to connect a remote

pump start or stop button. This input is intended for a

momentary push-button and can start or stop a pump-over.

This is an optional feature.

Analog input/

output

AO 1

AO 1 sets the speed of the VFD (0 V-10 V). This is an optional

feature.

• 0.30 mm

2

–1.50 mm

2

• (22 AWG–16 AWG)

• Stranded wires and

twisted-leads cable

A525 Fermentation Tank Controller Installation Guide4

Loading...

Loading...