P78 Series Controls for Dual Pressure Applications Installation Instructions

7

Table 3: Adjusting P78 Dual Pressure Controls

Manual Reset Operation

Pressure controls with the Manual Reset option, lock out when they reach Cut-out pressure and must be manually

reset by the user to restart the controlled equipment. The manual reset mechanism is trip-free and cannot be

overridden by holding the Reset Button down.

When a control requires a manual reset, first determine what caused the control to cut out, and allow the sensed

pressure to fall at least 44 psi (3 bar) below the Cut-out pressure. Then press and release the Reset Button on the

front of the control to restore normal operation of the controlled equipment (see Item 5, Figure 4).

Technical Specifications

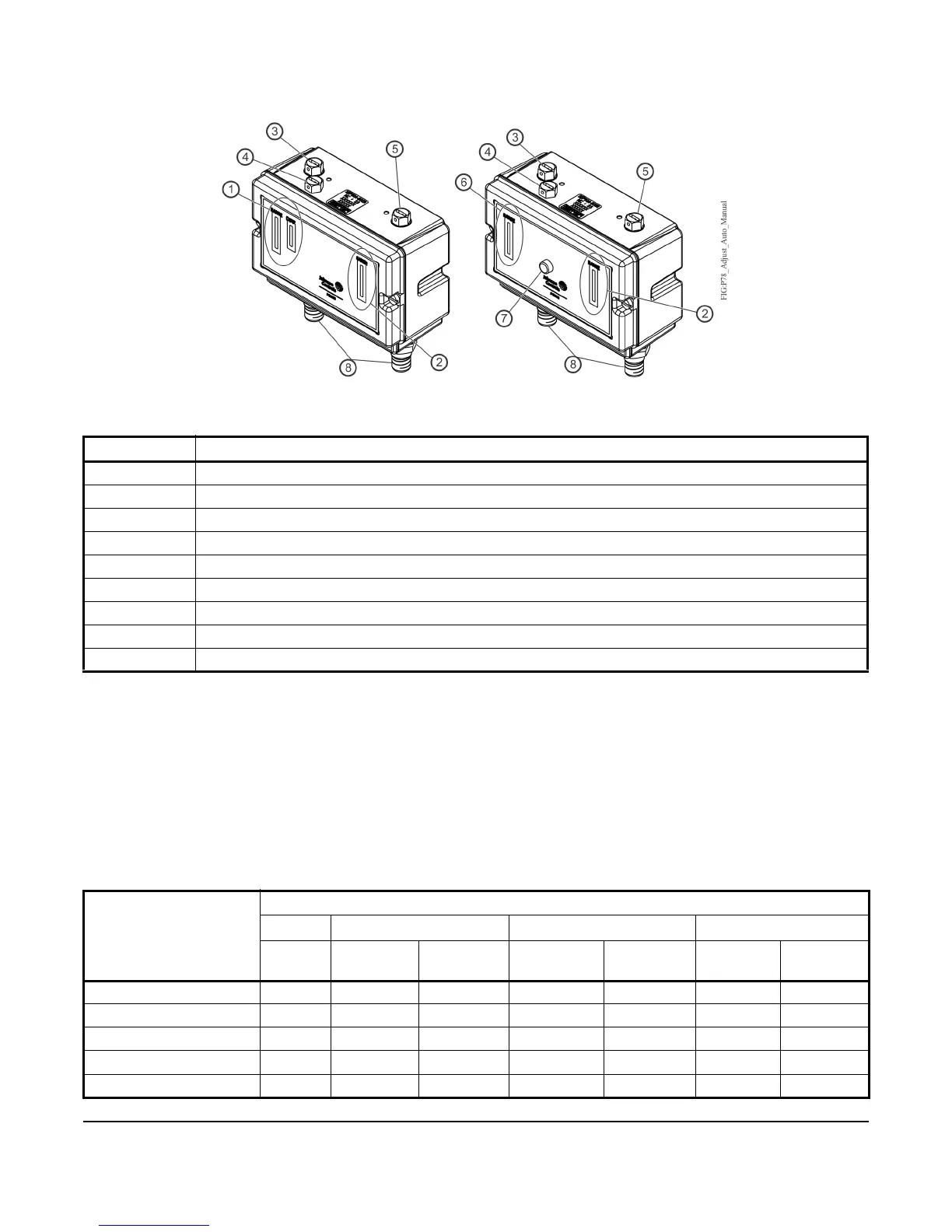

Callout Description

1 Low Side Range and Differential Scales

2 High Side Range Scale

3 Low Side Range Screw

4 Low Side Differential Screw

5 High Side Range Screw

6 Low Side Range Scale (only)

7 Reset Button

8 Pressure Connection

9 Adjustment Lock Plate (if applied)

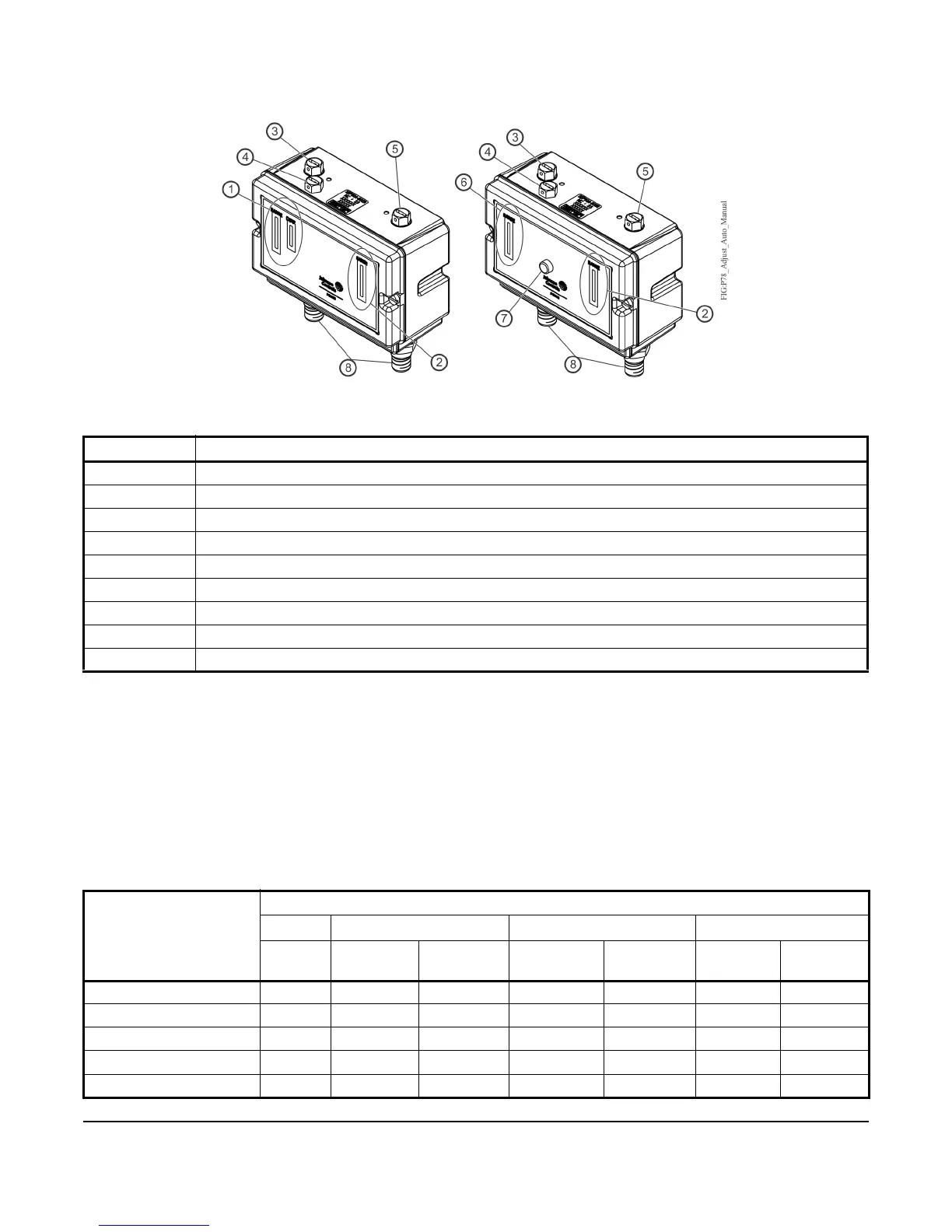

Table 4: P78 Series Electrical Ratings

Volts AC 50/60 Hz

UL60730

24 120 208 240

– Primary

Contact

Secondary

Contact

Primary

Contact

Secondary

Contact

Primary

Contact

Secondary

Contact

Horsepower – 1 .33 1 0.75 1 1

Full Load Amperes – 16 7.2 9.2 7.6 8 8

Locked Rotor Amperes – 96 43.2 55.2 45.6 48 48

Resistive Amperes 16/8 16 8 10 8 10 8

Pilot Duty VA 125/125 720 720 720 720 720 720

Note: The Primary Contact is A–C; the Secondary Contacts are A–B and A–D.

Figure 4: Adjusting the P78 Dual Pressure Controls

Manual Reset Lockout

Automatic Reset

Loading...

Loading...