3

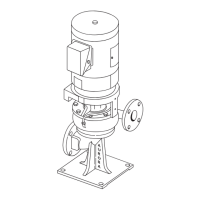

MODELS 411 & 481, 412, 413 & 483

However, when the pump is exposed to dirt contamination, high

temperatures (200F. or above) or a wet location, the oil may

have to be changed every 2 or 3 months.

The motor that drives your Aurora pump may or may not

require lubrication. Consult the manufacturer’s recommenda-

tions for proper maintenance instructions.

REPAIRS

The pump may be disassembled using the illustrations and text

provided. Although complete disassembly is covered, it will

seldom be necessary to completely disassemble your Aurora

Pump.

The illustrations accompanying the disassembly instructions

show the pump at various stages of disassembly. The illustra-

tions are intended to aid in the correct identification of the parts

mentioned in the text.

Inspect removed parts at disassembly to determine their

reusability

. Cracked castings should never be reused. All pack-

ing and gaskets should be replaced with new ones at reassembly

simply as a matter of economy; they are much less expensive to

replace routinely than to replace as the need accrues. In general

it is economical to return to the manufacturer for repair only the

motor and motor controller.

DISSASSEMBLY OF THE PUMP

- Disassemble only what is

needed to make repairs or accomplish inspection. Proceed to

disassemble the pump as follows: (see figure 4 for Model 411

& 481, Figure 5 for Model 412 and Figure 6 for Model 413 &

483.

1. Break the electrical connections to motor or take other

steps needed to prevent drive unit from being unintentionally

energized during disassembly.

2. Close such valves or flow-control devices necessary to

make certain flow of liquid will no take place during disas

s

embly.

NOTE

Discharge and suction piping need not be disturbed unless

complete pump assembly is to be removed.

3. Drain liquid from pump by removing plugs (1 and 2).

Disconnect any flushing, cooling, by-pass lines that are con

nected to parts that will be removed.

4. Loosen and remove capscrews (6) securing casing half (8)

to remainder of pump assembly.

NOTE

If pump being disassembled is size 4x5x11 or larger, remove

capscrews (7) also before attempting to separate casing ha

lves

If possible drain and/or flush pump to remove any corrosive

or toxic liquid before attempting further disassembly. Many

units will not have drain taps.

5. Make certain all securing capscrews are removed, then

carefully remove casing half (8) using hoist or crane with a

sling attached around cast hooks on the casing and under the

casing.

Use extreme care when casing comes loose that it does not

drop out of sling, as this would cause extensive damage to

other components of p

ump.

6. Remove gasket (9) and scrape mating surface of casing

halves to remove pieces of gasket which have adhered in sep-

aration. Take care not to scratch or mar mating surface.

7. On Model 411, 481 and 413, 483 loosen flexible coupling

and slide the halves apart. On Model 412 pumps remove

flexible shafting.

B. Casing half removed.

C. Rotating element removed from casing half.

CAUTION

D. Outboard rotating element components removed

illustrating disassembly order.

E. Sleeve and thrust washer removed.

Loading...

Loading...