P/N 178556 6 Rev. D 6-26-09

F. CLEANING THE HIGH FLOW™ MANUAL AIR RELIEF

VALVE

1. Turn the pump off and shut off any automatic controls to ensure

that the system is not inadvertently started during servicing.

2. OPEN THE HIGH FLOW™ MANUAL AIR RELIEF

VALVE UNTIL IT SNAPS INTO THE FULL OPEN

POSITION, THEN WAIT UNTIL ALL PRESSURE IS

RELIEVED.

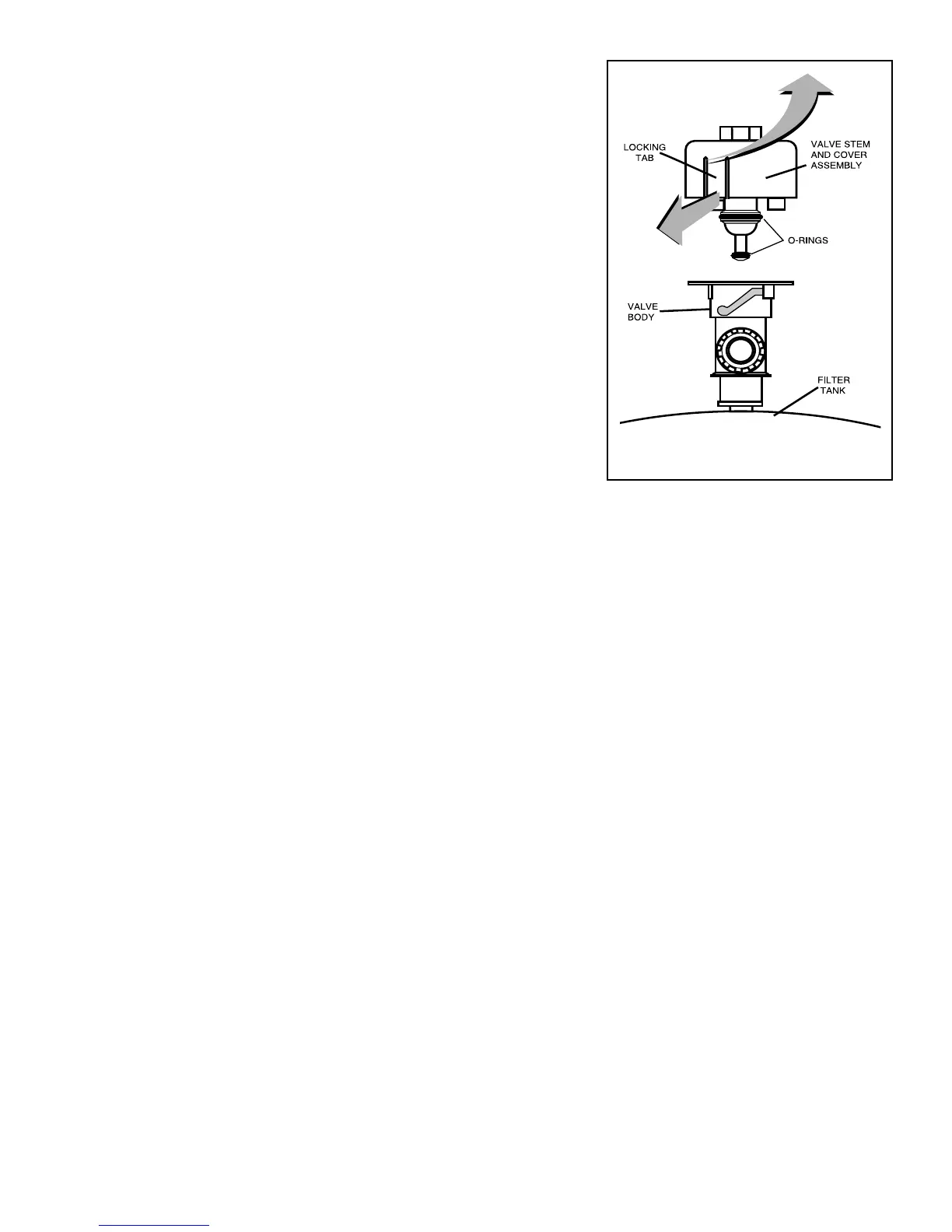

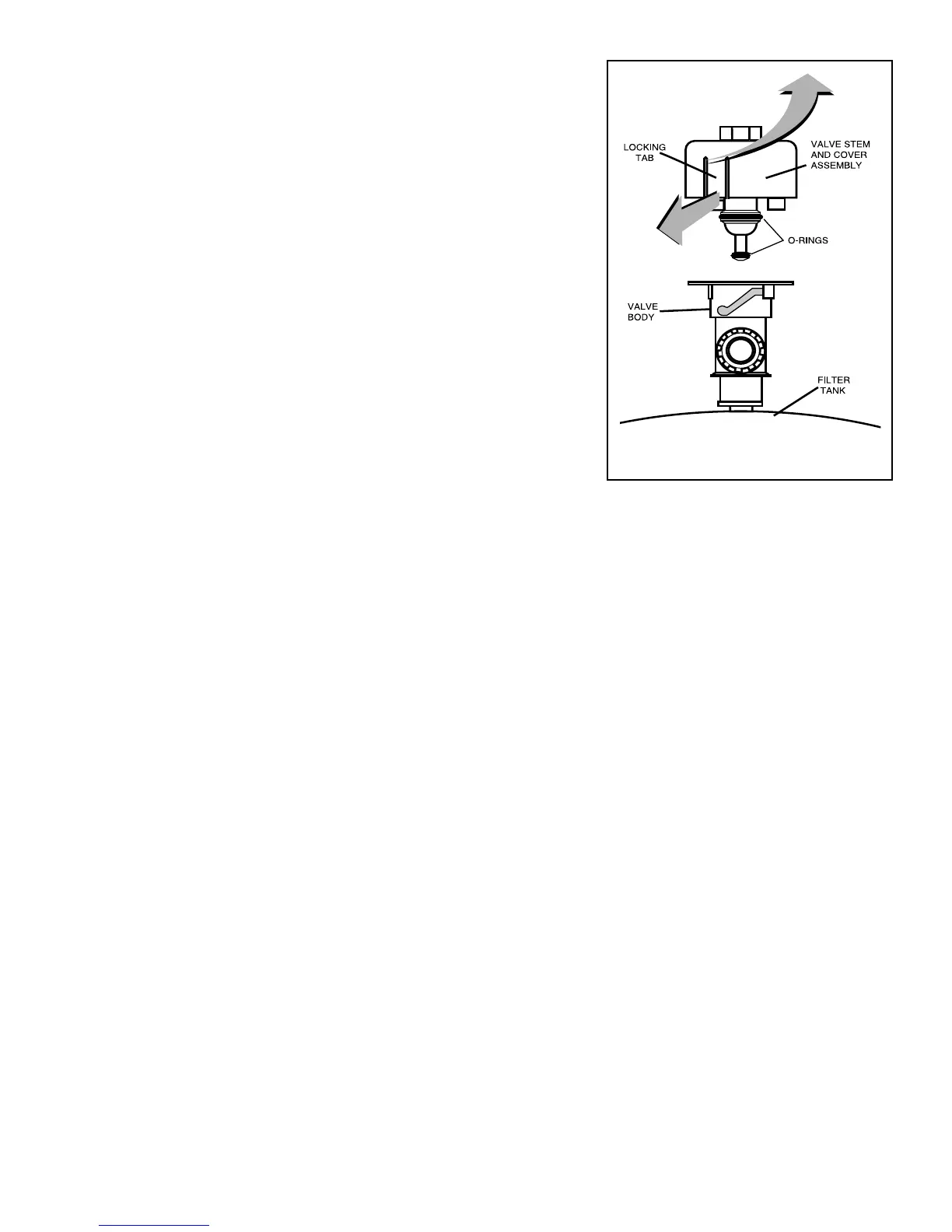

3. With the relief valve attached to the filter tank, pull out the

locking tabs and remove the valve stem and cover assembly with

a counterclockwise and lifting motion, see Figure 3.

4. Clean debris from the valve stem and body. Verify that the filter

tank's air passage is open by inserting a 5/16 in. drill bit through

the valve body. Verify that the O-ring are in good condition,

properly positioned, and lubricated with a silicone base lubricant.

5. Reinstall the valve stem and cover assembly with a downward

and clockwise motion until it snaps into position.

SECTION III. TROUBLESHOOTING

A. Air entering your filter is dangerous and can cause the lid to blow off. Correct any conditions in your

filtration system that allow air to enter the system.

1. Some common ways to identify air entering the system:

a. Low water level in pool or spa - skimmer is starving for water with pump running. Add water to

pool or spa.

b. Air bubbles or low water level in pump hair and lint pot are caused by; low water level, clogged

skimmer basket, split suction cleaner hose, leak in pump hair and lint pot lid, or leak in pump

suction line.

c. Air bubbles coming out of water return lines into pool or spa with pump running, see items 1.a

and 1.b of this section.

d. Air is discharged from the air relief valve on top of the filter when the valve is opened with the

pump running, see items 1.a and 1.b of this section, above.

B. Until the water initially put into the pool has been completely filtered, short filter cycles in between

cleanings are normal. In most cases pool owners are dismayed by the undesirable color and appearance

of water in a newly filled pool. Plaster dust can be responsible for short filter cycles, requiring frequent

cleaning.

C. If pressure drops on gauge, check skimmer basket and pump basket first for debris. If the baskets are

clean, shut off power to pump and turn off any automatic controls. Then turn motor shaft with your

fingers. If it turns freely then the pump must be disassembled and the impeller checked to see if it is

clogged. If it is not frozen or clogged then there is an obstruction in the line between the pool and the

pump.

D. The pressure gauge is an important part of the filter system. It is your primary indicator of how the

system is operating. Maintain your pressure gauge in good working order. Check the operation of your

pressure gauge in the following manner:

1. The pressure gauge should go to zero (0) when the system is turned off and pressure is relieved.

2. The pressure gauge should indicate pressure when the system is operating.

3. The pressure gauge should be readable and not damaged in any way.

4. Replace the pressure gauge if it is not meeting the requirements of items D.1 through D.2 of this section,

above.

Figure 3.

Loading...

Loading...