2017-12

10

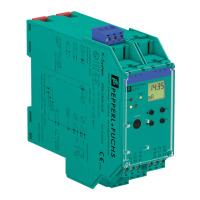

Functional Safety KF**-CRG2-(Ex)1.D

Planning

3.2 Assumptions

The following assumptions have been made during the FMEDA:

• Failure rate based on the Siemens standard SN29500.

• Failure rates are constant, wear is not considered.

• External power supply failure rates are not included.

• The collective error message output is not safety relevant.

• The indication of a dangerous failure (via fault bus) is detected within 1 hour by

the programmable logic controller (PLC).

• The safety-related device is considered to be of type B device with a hardware

fault tolerance of 0.

• The device will be used under average industrial ambient conditions, which

are comparable with the classification "stationary mounted" in

MIL-HDBK-217F. Alternatively, the following ambient conditions are assumed:

• IEC/EN 60654-1 Class C (sheltered location) with temperature limits in the

range of the manufacturer's specifications and an average temperature of

40 ºC over a long period. The humidity level is within manufacturer's rating.

For a higher average temperature of 60 ºC, the failure rates must be

multiplied by a factor of 2.5 based on experience. A similar factor must be

used if frequent temperature fluctuations are expected.

• Since the outputs of the device use common components, these outputs must

not be used in the same safety function.

• Features that extend the reaction time of the output are not considered within

the specified reaction time. It is the user's responsibility to consider this time

within the safety calculation.

• Observe the useful lifetime limitations of the output relays according to the

datasheet.

• The device must be configured for the required safety function before the

commissioning. During the operation any change of the configuration is not

allowed. See chapter 4.1.1.

• The device configuration is protected by a password against changing.

Analog Output

• The application program in the programmable logic controller (PLC) is

configured to detect underrange and overrange failures.

Loading...

Loading...