6. For best results, use only hydraulic

uidwitharatingofSAE20forrells.

Checkuidlevelwithpumpinfullydown

position.

7. Change the hydraulic oil at least once

every three years:

a. SetPump(1)atonalevelsurface.

b. Remove the Fill Screw (A). The O-

ring (B) should come off with it.

c. Tip the pump to allow the old hy-

draulic oil to drain out of the housing

completely, and dispose of the old

hydraulic oil in accordance with local

regulations.

d. With the Pump upright, completely

llthehousingwithahighquality

hydraulic oil (not included) until the

oil just begins to run out of the oil

llhole.BeVERYCAREFULnotto

allow dirt or foreign matter into the

system.

CARE & MAINTENANCE

A

B

C

D

Fig. 5

e. Make sure the O-ring (B) is still in

place around the Fill Screw (A) and

thread the Fill Screw into the Pump

securely. Do not use thread seal

tape.

f. Firmly close the Release Valve (C) by

turning it clockwise.

g. Clean with a clean cloth using a

detergent or mild solvent.

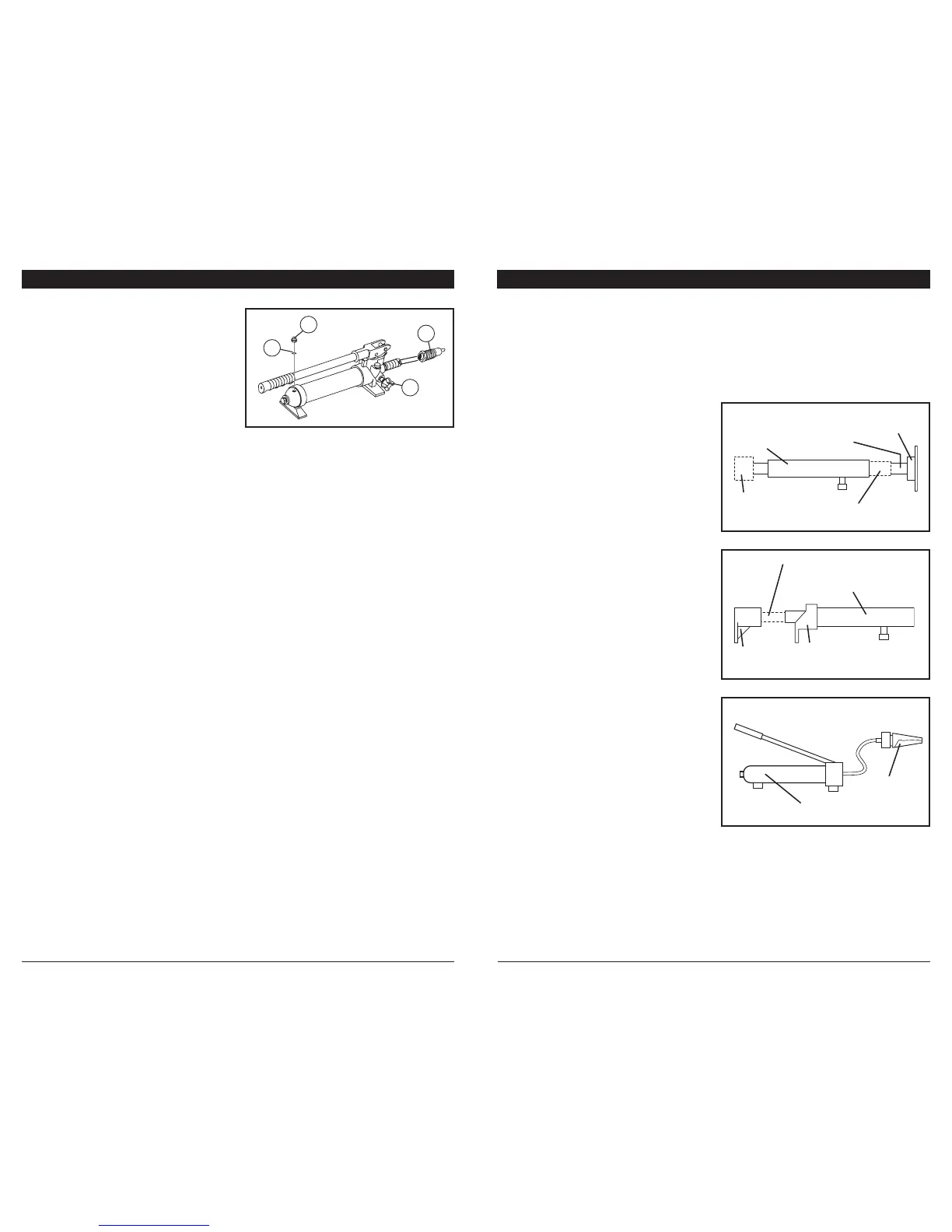

Ram Setup:

Note: When positioning the Ram (3) use a

smaller attachment on the side that

is to be bent instead of the stationary

side. If the stationary side is in dan-

ger of being bent or damaged, place

a block of wood or other material

behind the Flat Base (9) to distribute

pressure over a greater area.

1. Clean the end of the Hose and the inlet

on the Ram (3). Unscrew and save the

End Plugs located on the end of the hose

and Ram (3).

2. Attach the Hose to the Ram.

3. Assemble attachments as shown in

gure1and2.

Note: If using the Plunger Toe and Ram

Toe, thread the Ram Toe onto the

Ram completely and align the

Plunger Toe to it.

Spreader Wedge Setup:

The Spreader Wedge (2) is used when the

Ram(3)istoolongtotbetweenthestation-

ary side and the damaged area.

1. Clean the end of the hose and the inlet on

the Spreader Wedge (2).

2. Unscrew and save the End Plugs located

on the end of the hose and Spreader

Wedge (2).

3. Attach the Hose to the Spreader Wedge

(2),asshowningure3.

SETUP INSTRUCTIONS

Note: The Flange Base and Flange Head must only be used together to prevent an off

center load.

Note: When positioning the Ram (3) use a smaller attachment on the side that is to be

bent instead of the stationary side. If the stationary side is in danger of being bent

or damaged, place a block of wood or other material behind the Flat Base (9) to

distribute pressure over a greater area.

Fig. 1

Fig. 2

Fig. 3

Ram (3)

Ram (3)

Spreader

Wedge (2)

Male

Connector (14)

Extension Bars (5-8)

as needed

Extension Bars (5-8)

as needed

Pump (1)

V-base (13) or

Flat Base (9)

Cap Head (15)

Rubber Head (16)

or Wedge Head (12)

Plunger

Toe (11)

Ram

Toe (10)

Loading...

Loading...