1. Check the Hydraulic Fluid Level, following

the instructions in the Bleeding the pump

section, if needed.

2. Determine which direction the frame

needs to be bent.

3. Remove any obstructions that could be

damaged or are in the way.

Note: When using the Pump (1) in a verti-

cal position, keep the Hose (3) end

of the Pump downward.

4A. Using Ram (2):

a. Connect the appropriate Base

(13,15,17) to the stationary side of

the Ram (2), and connect the ap-

propriate head to the pushing end of

the Ram.

GENERAL OPERATION

NOTICE During shipment or handling, air in the pump can become trapped in the

hydraulic system causing the pump to malfunction.

BEFORE USE

Bleeding The Pump:

1. SetPump(1)atonalevelsurface.

2. Remove the Fill Screw (A). The O-ring (B) should come off with it.

3. Theuidlevelshouldbenearthebottomoftheopening.Ifrequired,addhighgrade

hydraulicuid.

4. Make sure the O-ring (B) is still in place around the Fill Screw (A) and thread the Fill

Screw into the Pump securely. Do not use thread seal tape.

5. Firmly close the Release Valve (C) by turning it clockwise.

6. Press the tip of the Coupling (D) against a hard surface and pump the pump handle.

7. Continuepumping,untilthehydraulicuidcomingouttheendofthecouplertipisfree

of air bubbles.

8. Rechecktheuidlevelandadduidif

necessary.

9. Turn the Release Valve counterclock-

wise to release the pressure in the pump

and hose.

10.Changethehydraulicuidyearly.

Remove the Fill Screw (A) and tilt the

Pump(1)todrainouttheolduid.Rell

thehydraulicuidandbleedthesystem

several times to ensure all air is out of

the system.

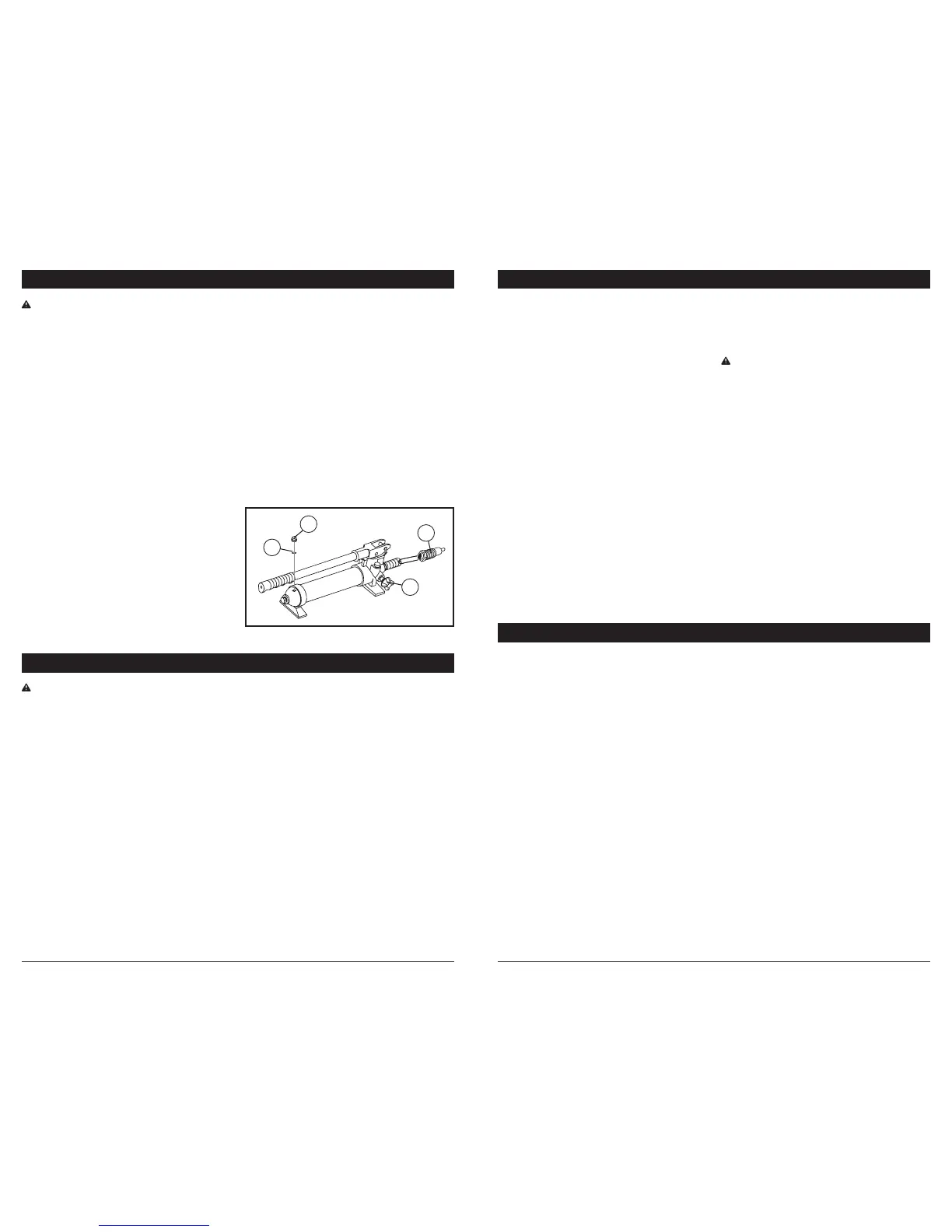

A

B

C

D

Fig. 4

WARNING: Read and understand all the previous sections before use of this product. Failure to

comply with those sections may result in serious personal injury and/or property damage!

Note: When repairing larger body panel

dents such as a dented door, fender

or quarter-panel use the Rubber

Head (11) on the pushing end.

b. If using the Flange Base (15) or

Flange Head (14): Thread the Flange

Base onto the Ram completely and

align the Flange Head to it. The

Flange Base and Flange Head must

only be used together to prevent off-

center load.

c. Position the Ram (2) so that the Base

is resting against a frame member

opposite the damaged area. It must

also be in line with the direction in

which the damaged area needs to

be pushed. The vehicle body part

1. Before each use, inspect the general

condition of the product. Check for

broken, cracked, or bent parts, loose or

missing parts, and any condition that

may affect the proper operation of the

product. Any equipment that appears

damaged in anyway must be removed

from service. Have the problem cor-

rected before further use. DO NOT use

damaged equipment.

2. Replace worn or damaged parts with

Performance Tool® replacement parts.

Besurethatonlyqualiedperson-

nel perform repairs. DO NOT attempt

to weld, rivet or otherwise repair this

device.

CARE & MAINTENANCE

Monthly maintenance is recommended. Lubrication is critical to the ram and

pump as they support heavy loads. Any restriction due to dirt, rust, etc. can cause

either slow movement or cause extremely rapid jerks, damaging the internal com-

ponents. The following steps are designed to keep the pump and ram maintained

and operational.

GENERAL OPERATION

must be stronger than the area to be

bent or it may be damaged. A block

of wood or a towel may be used to

protect the body part.

d. Aim the pushing end towards the

area that needs to be repaired,

and slowly apply pressure with

the Pump (1).

Note: To prevent damage, do not overex-

tend the Ram.

4B. Using Spreader Wedge (10):

a. Place the Spreader Wedge (10) so

that the hinged (pushing) arm is rest-

ing against the part to be moved and

the stationary arm is resting against a

non-movable base.

b. Carefully hold the Spreader Wedge

in position and apply the Pump (1)

pressure.

5. Once both ends have made contact, move

as far away as possible and continue to

slowly apply pressure to the damaged area

until the desired bend has been made.

CAUTION Keep hands away from contact

areas and tight spaces. The

tool may slip and cause injury.

6. When the damaged area has been bent to

the desired position, slowly turn the Release

Valve (10C) counterclockwise to release the

hydraulic pressure and remove the Ram (2)

or Spreader Wedge (10).

7. Clean all hydraulic ports and cover them

with clean End Plugs to prevent contamina-

tion and damage.

3. Before each use, thoroughly test the

equipment for proper operation prior to

its actual use. If the equipment appears

not to be working properly, follow bleed-

ing instructions on page 6.

4. When the product is not in use, ram and

pump piston should be in fully down

position to keep their machined surfaces

free from corrosion.

5. Keep the surface of this equipment and

itsaccessoriesfreeofhydraulicuid

and grease. Use only a mild detergent

and damp cloth when cleaning. Do not

useaammableorcombustiblesolvent

to clean this tool or its accessories.

Loading...

Loading...