6

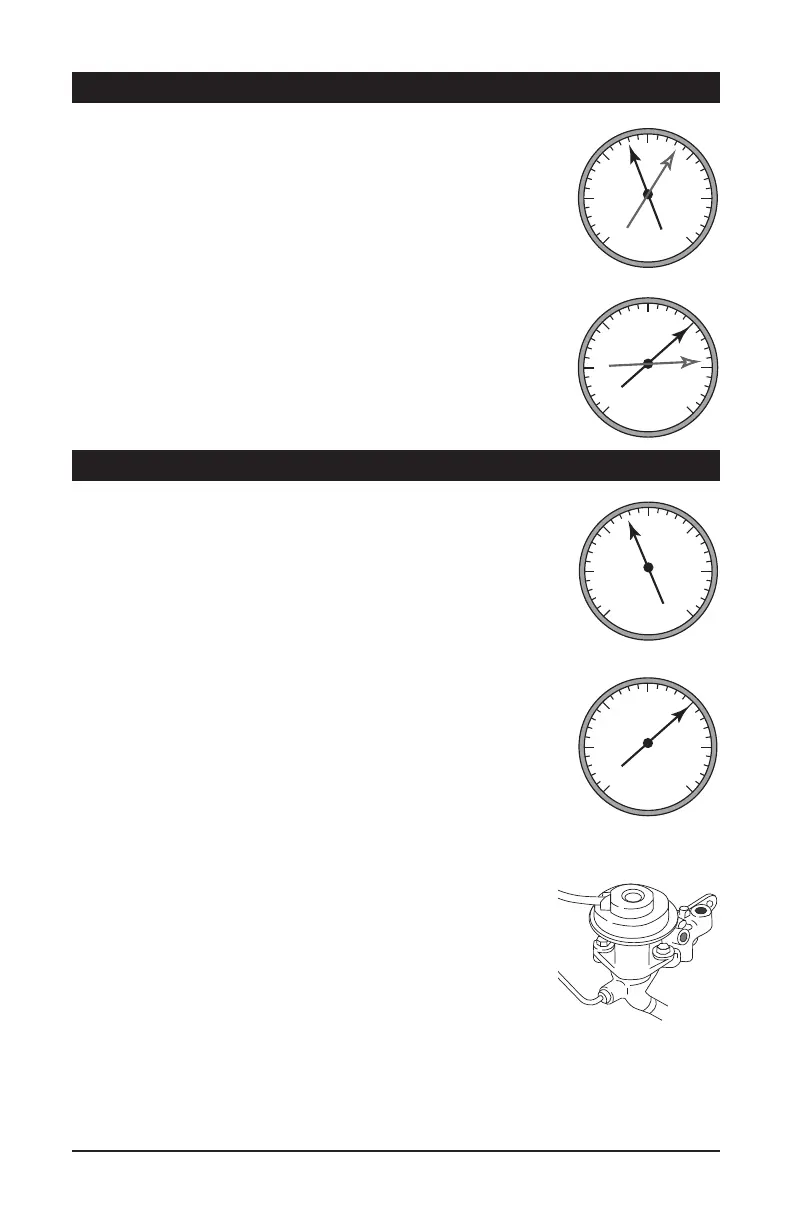

INTAKE MANIFOLD LEAK

1. With the vacuum pump connected to an intake manifold

vacuum port.

2. Start engine, bring to normal temperature and let idle.

3. Look at the needle’s movement on the gauge.

• If you have a bad gasket, or cracked hose this could

cause air to leak into the intake system. If this happens,

the needle will read about 4 to 9 in. of Hg below normal,

and will remain steady.

EXHAUST GAS RECIRCULATION (EGR)

1. With the vacuum pump connected to an intake manifold

vacuum port.

2. Start engine, bring to normal temperature and let idle.

3. Note the needle’s movement on the gauge.

• The needle should read 16-22 in. of Hg and hold steady.

and will remain steady.

4. Increase the engine speed to approx. 2000 RPM.

• As the speed increases slowly, so should the vacuum.

This indicates the EGR valve is operating properly.

• If the needle drops, moving toward zero you have a

malfunctioning EGR valve.

• To test:

1. Remove the EGR valve from the manifold.

2. Connect your vacuum tester to the diaphragm on the

EGR valve.

3. Pump the trigger of your tester building vacuum. The

needle should not move and hold steady. If the

needle starts to drop, your EGR valve has a crack/

hole in the diaphragm.

TESTING PROCEDURES

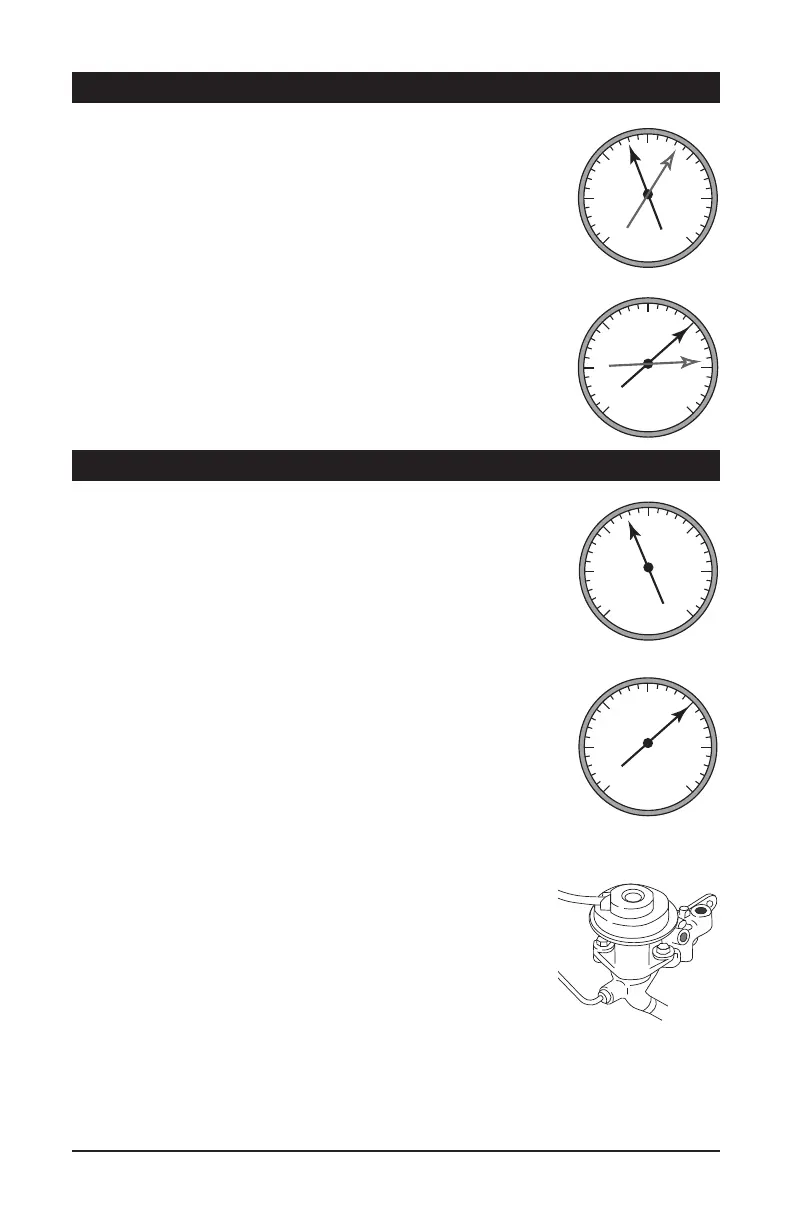

LEAKING PISTON RING

• If you experience leaking rings the vacuum at idle will be low

with the needle holding steady between 12 and 16 in. of Hg.

1. To test open the throttle.

2. Increase the engine speed to about 2000 RPM.

3. Then close the throttle quickly and watch the needle of the

gauge. It should jump 2 to 5 in. of Hg above its lowest reading.

A lesser gain may indicate faulty rings, and a complete cylinder

leakage or compression test should be done.

IDLE AIR/FUEL MIXTURE

• A sweeping change of 4 to 5 in. of Hg back and forth at idle

indicates a rich fuel mixture. With a lean mixture the needle

will drop irregularly over about the same range.

ENGINE DIAGNOSTICS CONT.

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

EXHAUST GAS RECIRCULATION (EGR)

FUEL PRESSURE REGULATOR

ELECTRICAL /VACUUM SOLENOID

Loading...

Loading...