8

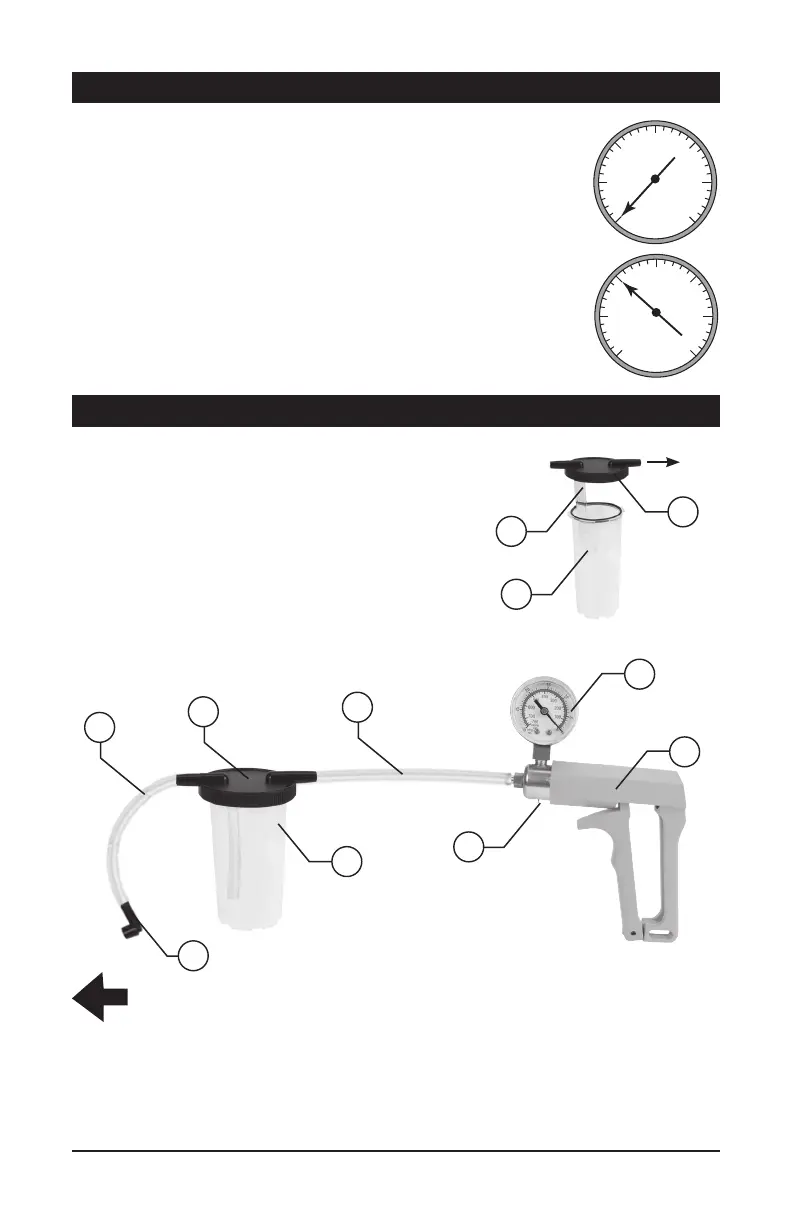

Figure A

TO WHEEL CALIPER

BLEEDER SCREW

1. Attach a 3 in. Vacuum Hose (8) to the bottom of the

Jar Lid (4). (See Figure A.)

2. Attach a 24 in. Vacuum Hose (7) to the top of the Jar

Lid (4) marked “TO PUMP”. Then, attach the other

end of the 24 in. Vacuum Hose (7) to the Vacuum

Pump (1). (See Figure B.)

3. Press one of the small rubber jar gaskets from the kit

into the inner lip of the 4.5 ounce Reservoir Jar (6).

Add a touch of light oil to the gasket to insure the

gasket won’t get pinched and for a good seal. Twist

the Jar Lid (4) onto the Reservoir Jar (6), it’s about

1/8 turn, do not over tighten.

4

To Pump

8

4. Connect the other 24 in. Vacuum Hose (7) to the remaining port on the Jar Lid (4) and

then connect the other end to the Brake Bleeder Screw Adapter (12).

5. With your finger over the adapter opening squeeze the handle of the Vacuum Pump (1)

a few times to create a vacuum in its Reservoir Jar (6). Press the the Vacuum Release

Valve (3) to release the pressure.

6

Figure B

7

4

7

2

1

3

6

12

1. Attach the vacuum pump to the bottom port and apply vacuum,

approx. 10 in. of Hg.

• The needle should hold steady and not bleed off.

If it does not hold, unit is bad and should be replaced.

2.

Repeat the procedure after the engine has warmed to normal temp.

• As vacuum is applied it should bleed off to zero. If it

holds steady, unit is bad and should be replaced.

NOTE: These thermal switch are needed to provide good drive ability.

It limiting the entrance of exhaust gases until the engine is warmed

up. Depending on the vehicles make your thermal switch may have

more than two ports. You may have three or four ports, the end

function is the same. They control vacuum going to different

applications until the engine has warmed to normal operating temp.

Consult your service manual for the type used on your vehicle.

TESTING PROCEDURES CONT.

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

BLEEDER PUMP ASSEMBLY

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Nornal

Leaking Intake Valve Timing

Ignition Timing

Misre

Clogged Exhaust

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Broken Valve Spring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Blown Head Gasket

Worn Valve Guides

Leaking Valve

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Fuel mixture

Leaking Piston Ring

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Vacuum Solenoid

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

0

5

10

15

20

25

30

Hg Hg

Vacuum

Gauge

Loading...

Loading...