19.

Adjusting

the

Lengthwise

Clamp

Travel

the

feed lengthwise

motion

is derived

from

the control slot on the back of feed cam

W {Fig. 17). Motion is

transmitted

from

the

roller

on

stud

P2 to

feed

regulator

V.

hinge

block

J (Fig. 14),

feed

regulator

post

K,

feed

plate

carrier

b

and

the

work

clamp.

To

adjust

the

lengthwise

clamp

travel,

move

hinge

block

J

downward

as

far

as

It will

go.

Turn

the

driving

pulley

by

hand

and

check

whether

the

needle

hole

remains

within

the

clamp

feet

slot

when

these

feet

reach

the

extreme

positons

of

their

lengthwise

travel.

If

the

machine

makes

a

bar-type

seam,

also

check

whether

the

plain

stitches

In

the

de

sign

are

correctly

centered

over

the

long

stitches.

To

check

this,

place

a

piece

of stiff

paper

under

the

clamp

and

examine

the

stitch

pattern.

For

a

precise

adjustment

of

the

feed

lengthwise

motion

loosen

the

nut

on

stud

P2

(Fig.

17)

and

move

the

stud

in

the

elongated

hole

of

feed

regulator

V,

as

required.

Then

tighten

the

nut

securely.

-01

•••Vx

• .

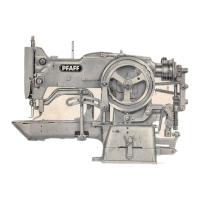

Fig.

17

20.

Timing

the

Feed

Cam

The

feed cam is located on the right hand

side

of the machine arm (as

seen

from the

operator). It controls both the feed lengthwise and

the

feed

across

motions. The feeding

motion

begins

after the

needle

has

risen

clear

of the fabric and

ends

before the

needle

penetrates

the material again. If the feeding begins too early or

ends

too late, the feed

ing motion is retimed by turning the cam on its shaft.

To

do

this,

loosen

nut

Y (Fig. 18)

and

stud

X

and

turn

the

feed

cam

on

the

transverse

shaft

(the

cam

can

be

turned

within

the

limits

set

by

stud

X riding in

the

elongated

hole

in

cam

positioning block 2). After

the

adjustment,

tighten

stud

X

and

nut Y

securely.

R

5793

r

W'

fell

Yt®fX

Fig.

18

Loading...

Loading...