7.

Threading

the

Needle

Lead

the

thread

from

the

spool

up

through

the

thread

guide

at

the

top

of

the

thread

stand,

then

down

to

spool

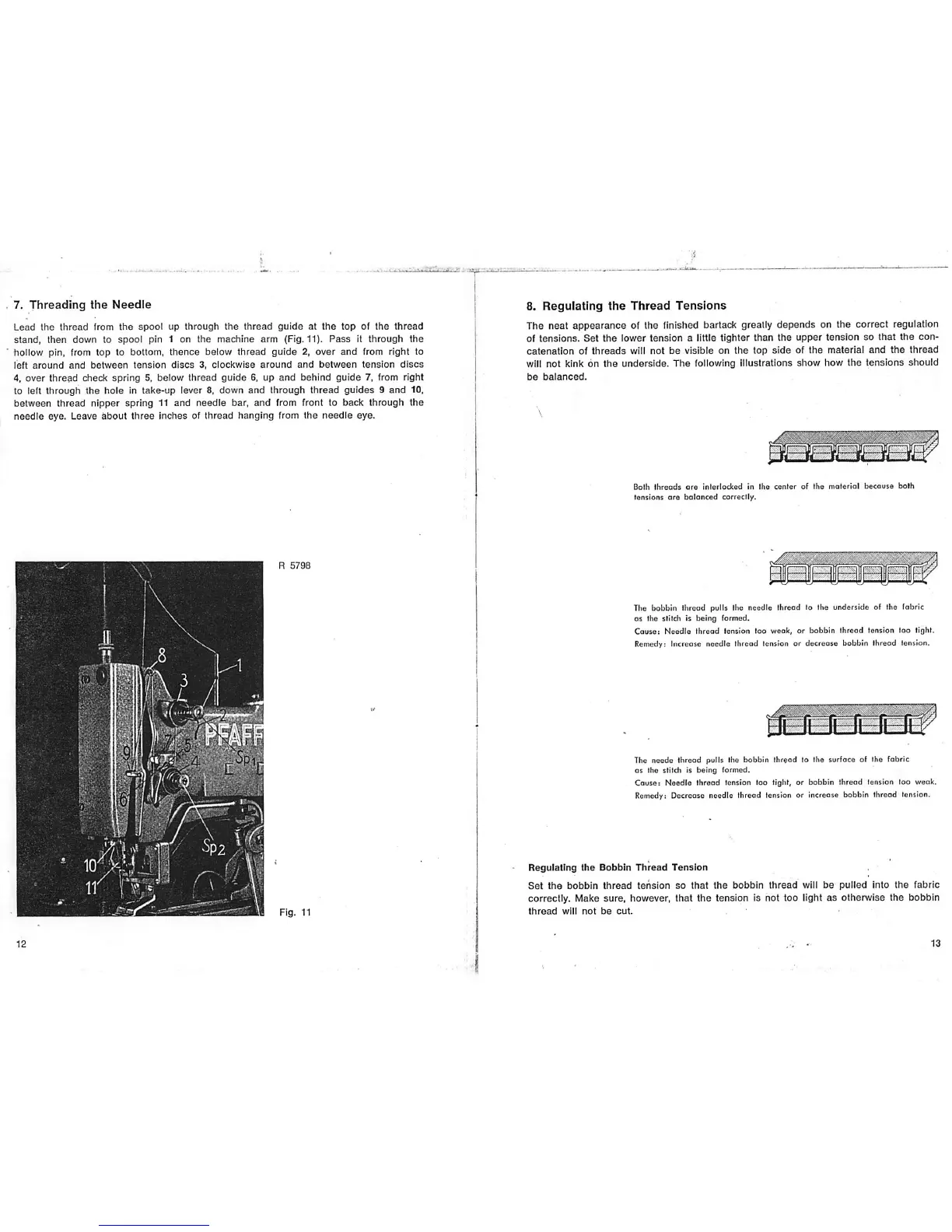

pin 1 on

the

machine

arm

(Fig. 11).

Pass

It

through

the

hollow pin, from top to bottom,

thence

below

thread

guide

2,

over

and

from right to

left

around

and

between

tension

discs

3,

clockwise

around

and

between

tension

discs

4,

over

thread

check

spring

5,

below

thread

guide

6, up

and

behind

guide

7, from

right

to left through

the

hole in

take-up

lever 8. down

and

through

thread

guides

9

and

10,

between

thread

nipper

spring

11

and

needle

bar,

and

from front to

back

through

the

needle eye. Leave

about

three

inches of thread hanging from the

needle

eye.

8.

Regulating

the

Thread

Tensions

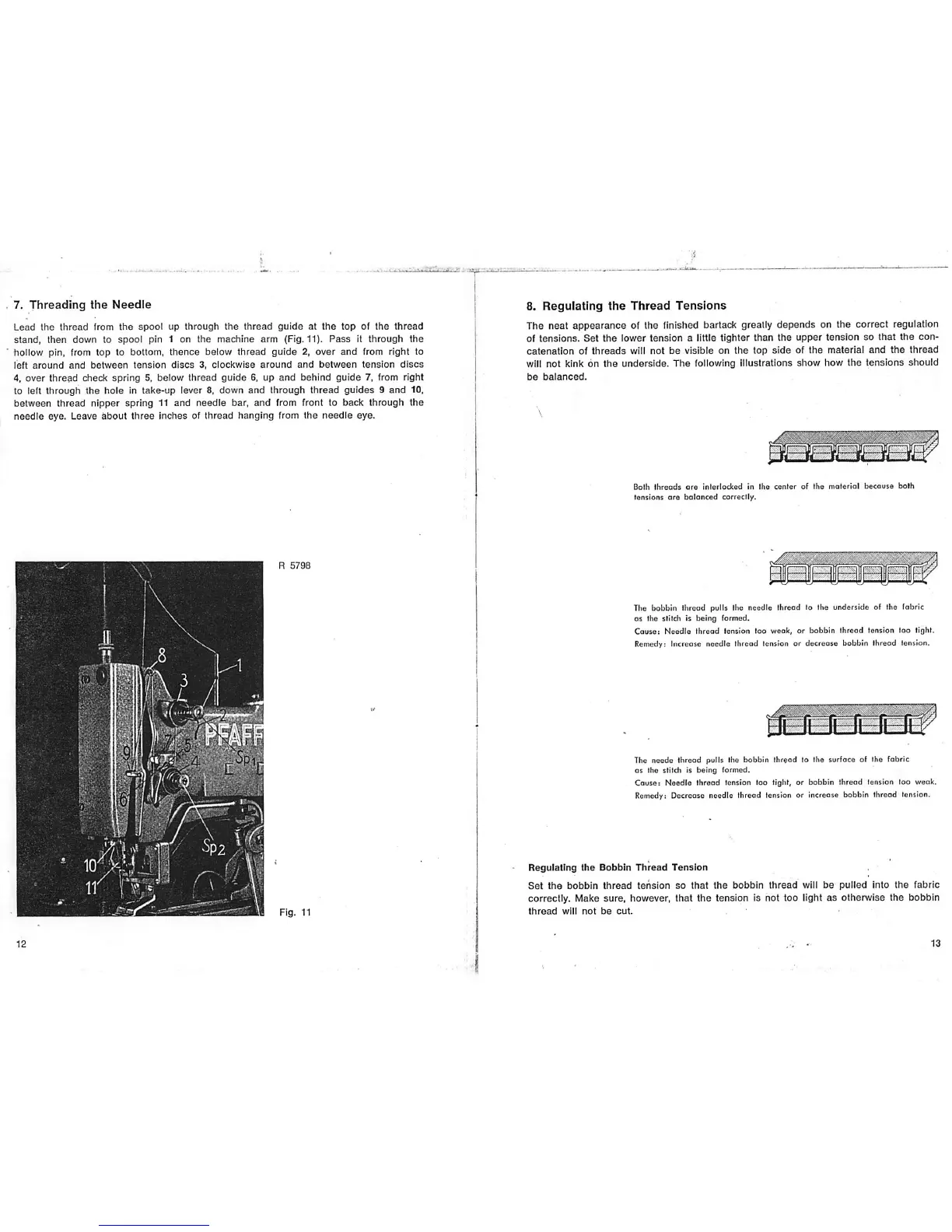

The neat appearance of the finished bartack greatly depends on the correct regulation

of

tensions.

Set

the

lower

tension

a little

tighter

than

the

upper

tension

so

that

the

con

catenation

of

threads

will not be visible on the top

side

of the material and

the

thread

will not kink on

the

underside.

The

following illustrations

show

hov/

the

tensions

should

be

balanced.

Both

threads

are

Interlocked

In the

center

oF the

material

because

both

tensions

are

baloneed

correctly.

The bobbin threod pulls the needle thread to the underside of the fabric

OS

the stitch Is being formed.

Causei Needle thread tension too weolc, or bobbin thread tension too tight.

Remedy: Increase needle threod tension or decreose bobbin thread tension.

The neede thread pulls the bobbin thread to the surface of the fabric

as the stitch is

being

formed.

Cause:

Needle

thread

tension too tight, or

bobbin

threod

tension too

weak.

Remedy: Decrease needle thread tension or increase bobbin thread tension.

Regulating

the

Bobbin

Thread

Tension

Set

the bobbin

thread

teiislon so

that

the bobbin thread will be pulled into the fabric

correctly. Make sure, however,

that

the

tension is not too light as otherwise the bobbin

thread

will

not

be

cut.

Loading...

Loading...