has almost reached the top of Its stroke.

Since

this spring is

subjected

to excessive

stress,

it may

become

weak

or

even

break

after

some

time by fair

wear

and

tear.

This

becomes

evident

when

the

machine

ceases

to

stop

evenly or when

the

needle

bar

and

the take-up lever do not always stop at the

same

positions. As a result, the

needle

may

stop

before

it

has

reached

the

top of Its

stroke

and

may be

broken

by

the

thread

wiper

upon lifting the work clamp. To correct this and similar conditions, exchange the buffer

spring,

as

follows:

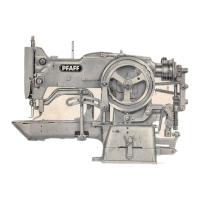

Remove tension

springs

N and 0 (Fig. 25), loosen

screw

K (Fig. 26), pull out hinge

stud

Q

and

strip

stop

motion lever p (Fig. 25)

and

brake

lever R.

Next,

take

out

the

four

screws

b,

strip

cap

ring A

and

remove

stop

cam

S

and

the

bro

ken

buffer

spring.

Insertion of a new spring Is greatly facilitated by the

use

of a special wrench (Fig. 27)

which will be

supplied

by us on

special

request.

v.'.usi

• -"-i

Fig. 26

Proceed,

as

shown

in Fig. 27, by

inserting

a

suitable

punch

into

hole

I of

the

driving

pulley. Then rotate the pulley until punch D rests

against

the bearing bracket.

Insert

the

buffer

spring

into

the

receptacle,

place

the

loose

check

block

on

the

stud

of

the

wrench,

and

push

the

wrench

over

the

end

of

the

arm shaft, with

the

loose

check

block

contacting

the

loose

end

of

the

spring.

Now, with

the

wrench

in

your

left

hand,

.

compress

the

spring

and

place

the

Novotext

segment

between

both

check

blocks. Make

sure

the

flat

sides

of

the

check

blocks

face

toward

the

segment.

Then

replace

the

stop

cam

and

the

cap

ring

and

screw

them

down. Attach

the

brake

lever

and

the

stop

motion

lever.

R'5788

Fig. 27

Loading...

Loading...