12.

Regulating

the

Thread

Tensions

Regulating

the

needle

thread

tension

i"urning tension nut M (Figs. 7 and 13) clockwise

increases

the tension, turning it

counter-

:iockwise

decreases

it.

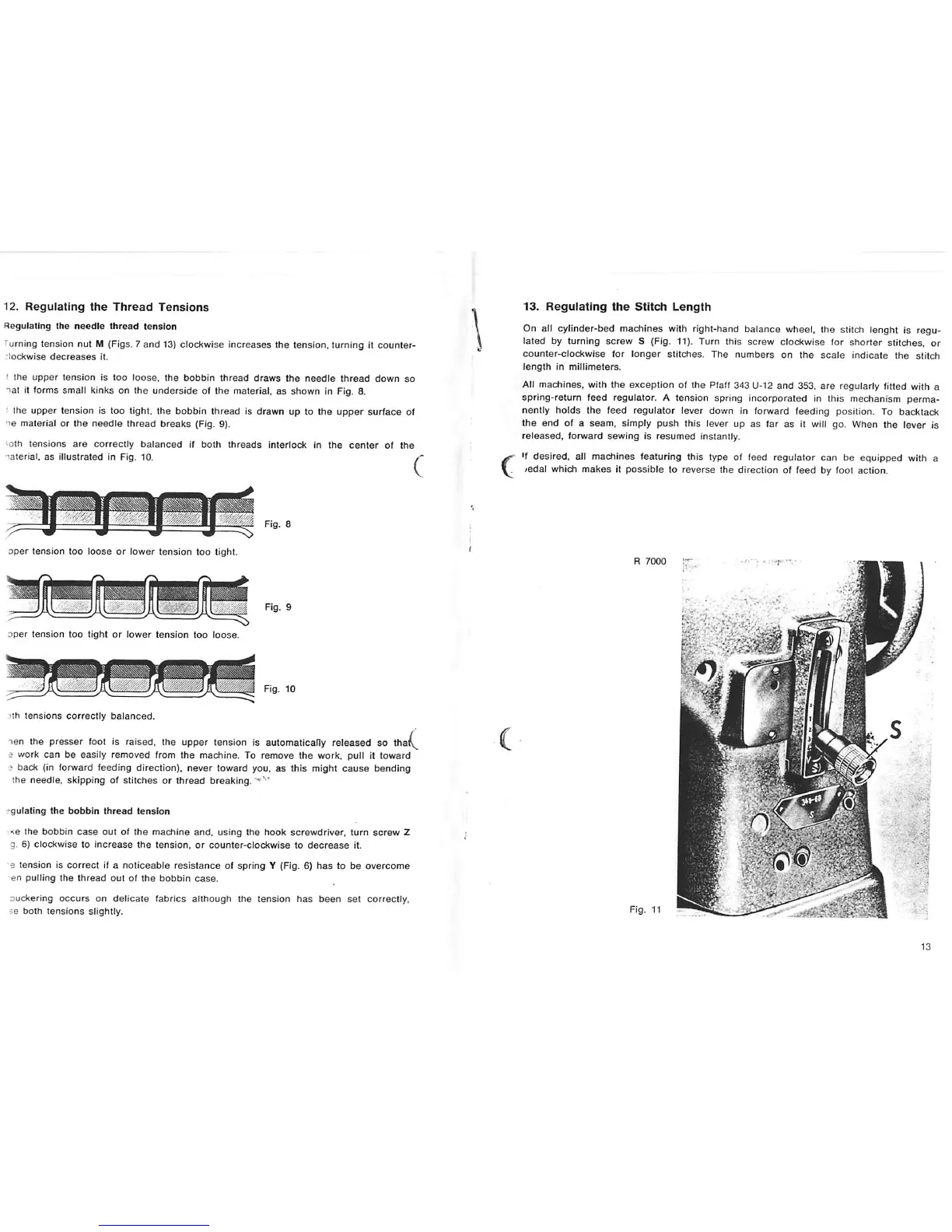

t

the

upper

tension

is

too

loose,

the

bobbin

thread

draws

the

needle

thread

down

so

lat

it forms small kinks on

the

underside

of

the

material,

as

shown

in Fig. 8.

: the

upper

tension

is too tight,

the

bobbin

thread

is

drawn

up to

the

upper

surface

of

">e

material

or

the

needle

thread

breaks

(Fig. 9).

-oth

tensions

are

correctly

balanced

if

both

threads

Interlock

in

the

center

of

the

material,

as

illustrated in Fig. 10. /

oper

tension

too

loose

or

lower

tension

too

tight.

jper

tension

too

tight

or

lower

tension

too

loose.

Fig. 10

ith

tensions

correctly

balanced.

-len

the

presser

foot

is

raised,

the

upper

tension

is

automatically

released

so

tha^

-3

work

can

be

easily

removed

from

the

machine.

To

remove

the

work, pull it

toward

?

back

(in

forward

feeding

direction),

never

toward

you.

as

this

might

cause

bending

the

needle,

skipping

of

stitches

or

thread

breaking.

egulating

tlie

bobbin

thread

tension

<e

the

bobbin

case

out

of

the

machine

and,

using

the

hook

screwdriver,

turn

screw

Z

g. 6)

clockwise

to

increase

the

tension,

or

counter-clockwise

to

decrease

It.

e tension is

correct

if a

noticeable

resistance

of

spring

Y (Fig. 6)

has

to be

overcome

en

pulling

the

thread

out

of

the

bobbin

case.

Duckering

occurs

on

delicate

fabrics

although

the

tension

has

been

set

correctly,

56

both

tensions

slightly.

13.

Regulating

the

Stitch

Length

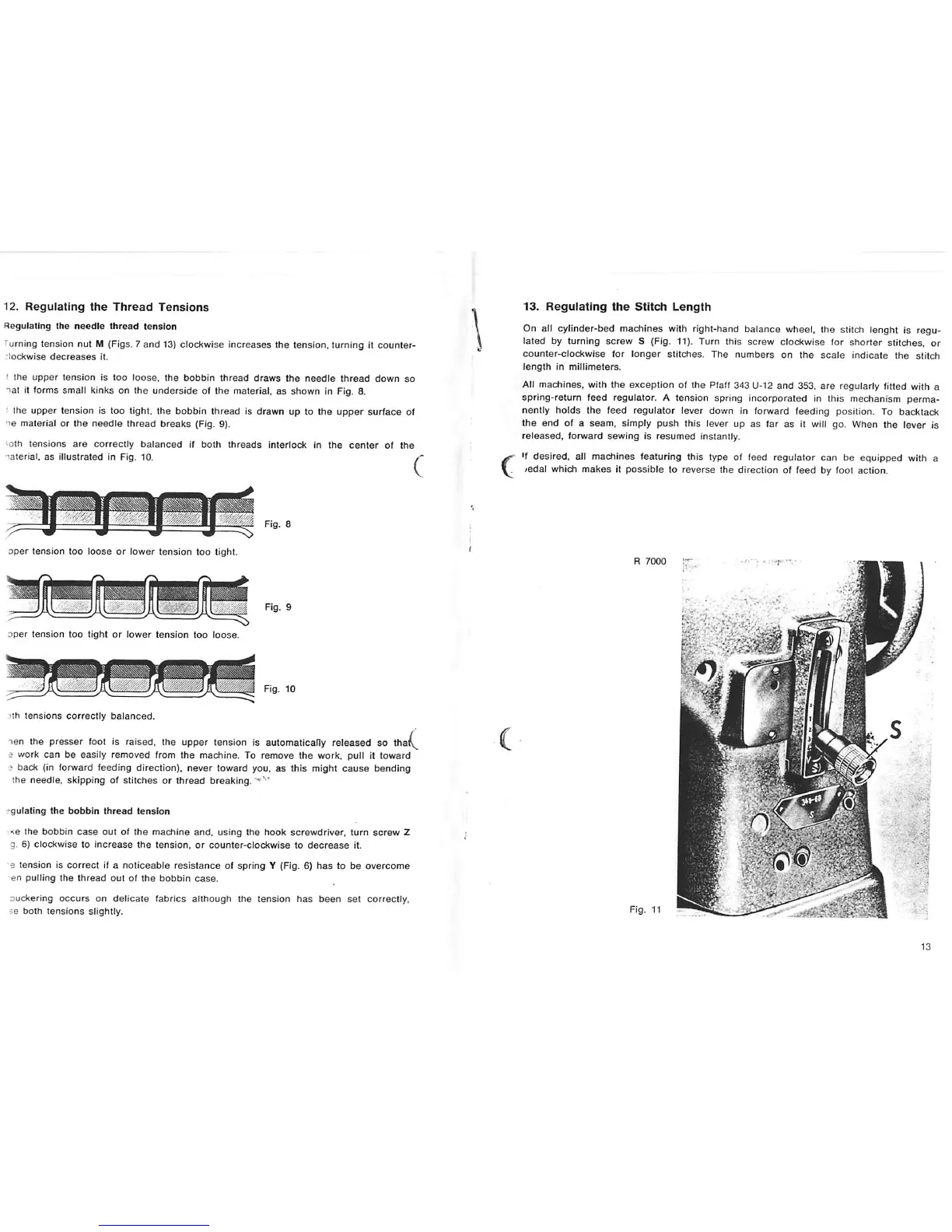

On all cylinder-bed machines with right-hand balance wheel, the stitch lenght is regu

lated by turning

screw

S (Fig. 11). Turn this

screw

clockwise for

shorter

stitches, or

counter-clockwise

for

longer

stitches.

The

numbers

on

the

scale

indicate

the

stitch

length

in

millimeters.

All machines, with the exception of the Pfaff 343

U-12

and 353,

are

regularly fitted with a

spring-return feed regulator. A tension spring incorporated in this mechanism

perma

nently holds the feed regulator lever down in forward feeding position. To backtack

the

end

of a

seam,

simply

push

this iever up as far as it will go. When the lever is

released,

forward

sewing

is

resumed

instantly.

C'f

desired,

all

machines

featuring

this

type

of

feed

regulator

can

be

equipped

with

a

;edal which makes it

possible

to reverse the direction of feed by foot action.

R

7000

:0m

Fig.

11

Loading...

Loading...