retained

until

sufficient

thread

has

been

wound

on

the

bobbin.

The

thread

wound on the bobbin pushes the com up

and

thereby stops the bobbin winder.

The

amount

of

thread

to be wound on the

bobbin

can be

regulated

by loosen

ing screw b and setting cam a higher or lower, as may be required. Set the

cam higher for more

thread,

or lower, for less

thread.

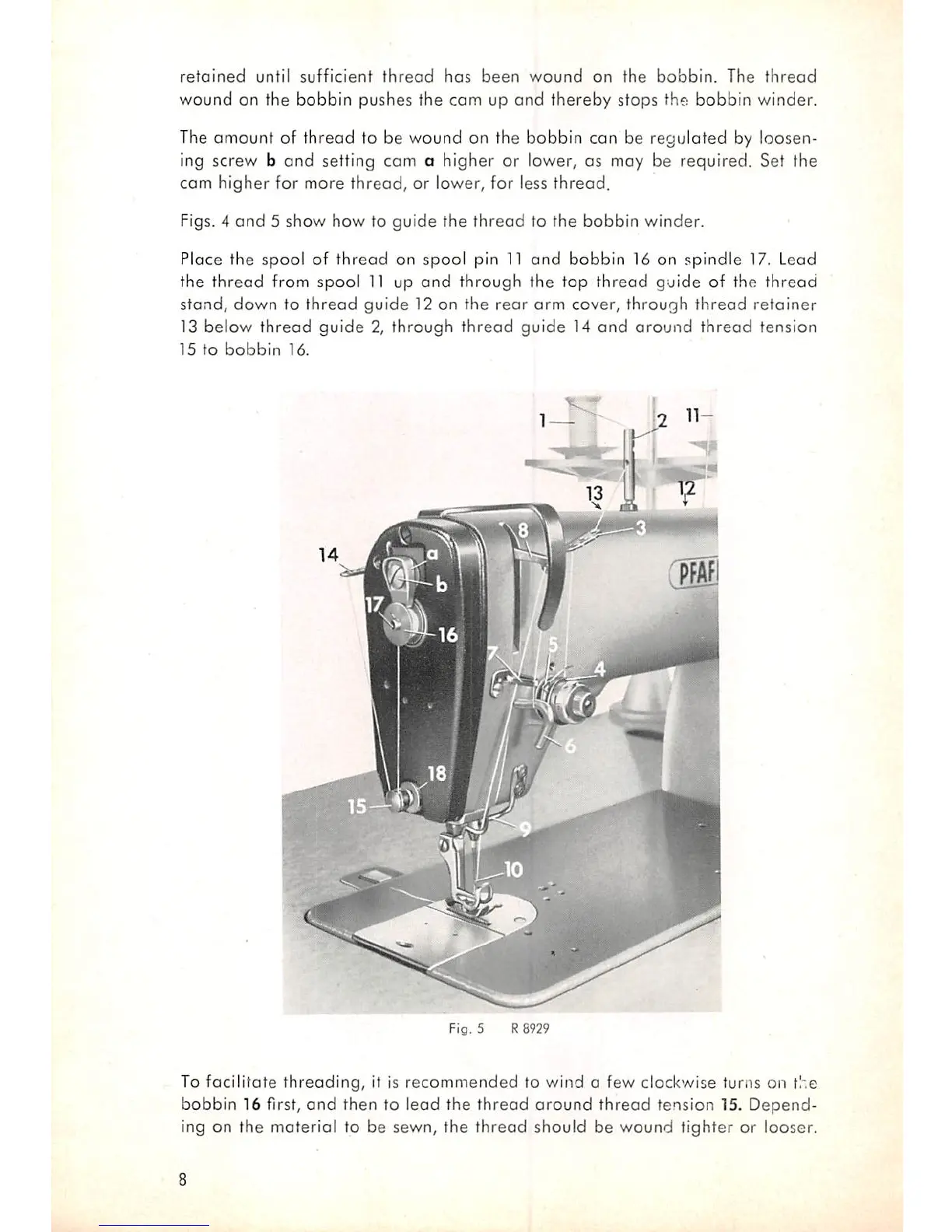

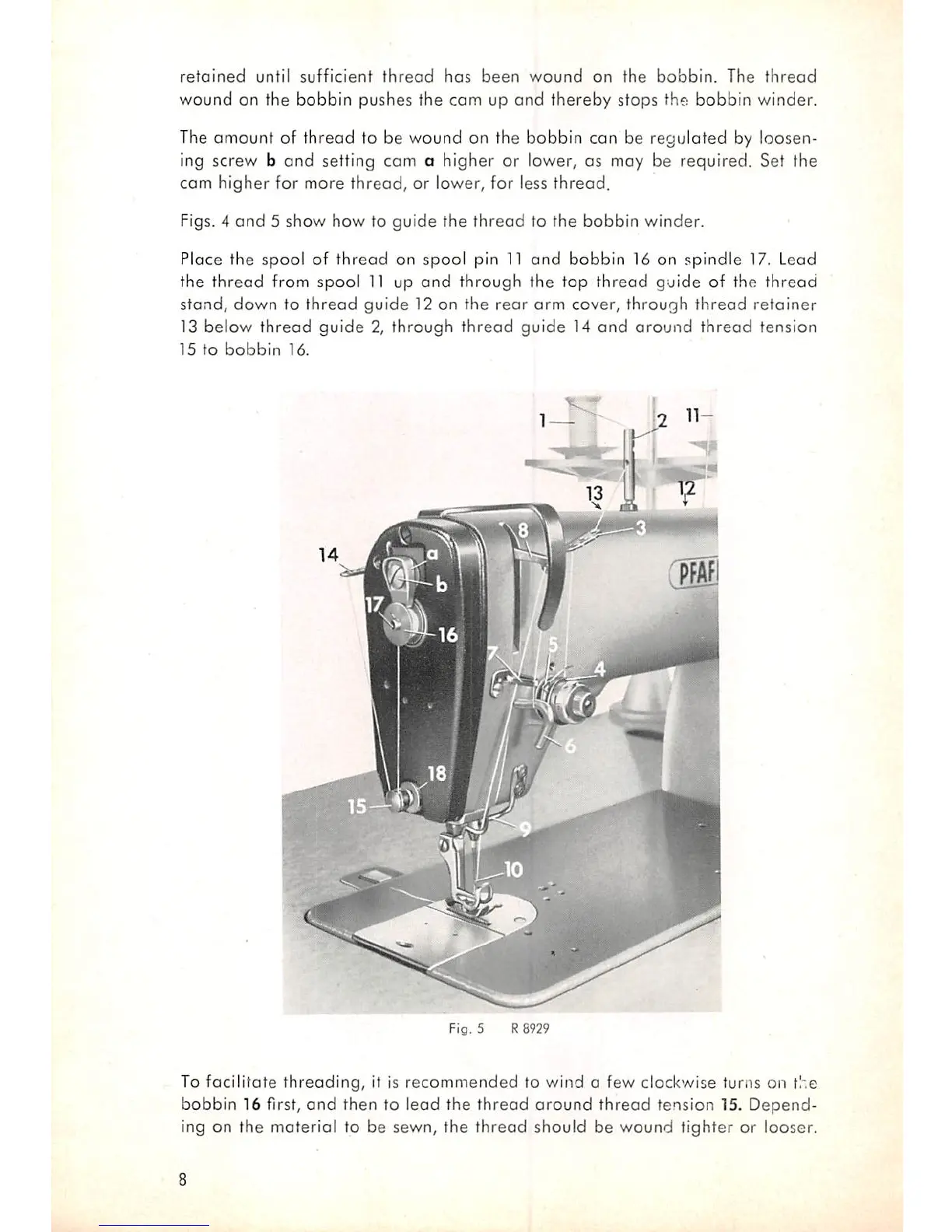

Figs. 4

and

5 show how to

guide

the

thread

to the

bobbin

winder.

Place the spool of

thread

on spool pin 11

and

bobbin 16 on spindle 17. Lead

the

thread

from spool

11

up

and

through the top

thread

guide

of the threod

stand,

down

to

thread

guide

12 on

the

rear

arm

cover,

through

thread

retainer

13 below thread guide 2, through thread guide 14 and around thread tension

15

to

bobbin

16.

T"

PFAFI

Fig. 5 R

8929

To facilitate

threading,

if is

recommended

to wind a few clockwise turns on the

bobbin 16 first,

and

then to lead the

thread

around

thread

tension 15. Depend

ing on the material to be sewn, the

thread

should be wound tighter or looser.

Loading...

Loading...