The thread tension is regulated by turning thumb nut 18 back of the tension

discs. Turn

the

nut

counter-clockwise

for a

tighter

tension,

or clockwise for a

looser

tension.

If the threod should pile up

at

one

end

of the bobbin, adjust the position of the

tension stud. The set screw securing this stud in position can be reached from

below.

5. Threading the

Needle

Because of the high speed of the seamer the smooth possoge of the thread to

the needle is especially importont.

Lead the thread from spool pin 1 up to the top thread guide of the thread

stand and down to thread guide 2. It is recommended to lead the thread first

through the vertical hole from top to bottom and then through the transverse

hole of the guide, as shown in Fig. 4 and 5, in

order

to prevent it from snarl

ing up on the guide and breaking,

Now lead the thread through two or three holes of thread retainer 3, as may

be required,

clockwise

around and between tension discs 4, through thread

check spring 5, under stock threod regulator 6, through thread guide 7, from

right to left through the hole in take-up lever 8, through thread guides 7 and 9

and from left to right through needle eye 10.

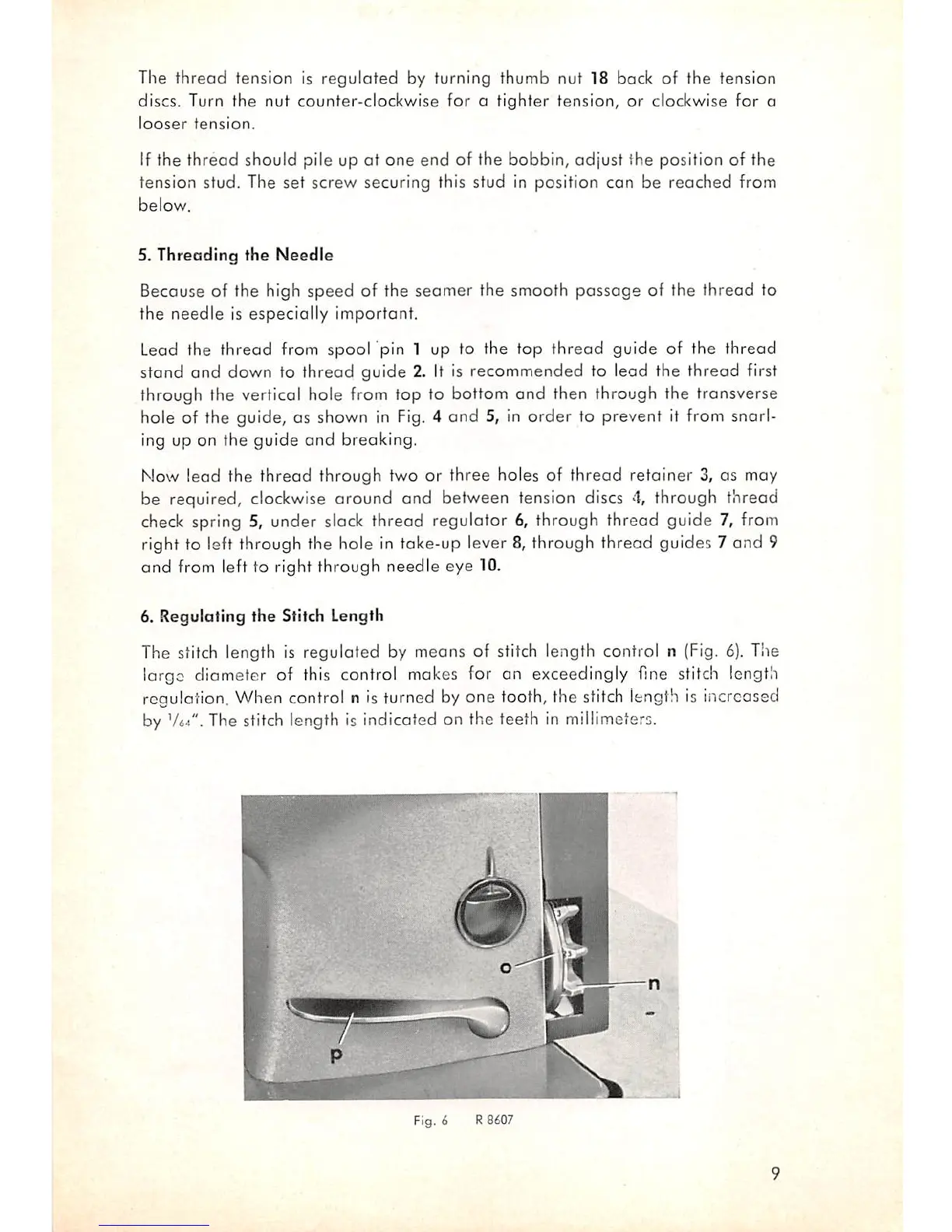

6. Regulating the Stitch Length

The stitch length is regulated by means of stitch length control n

(Fig.

6). The

large diameter of this control

mokes

for an exceedingly fine

stitch

length

regulation. When control n is turned by one tooth, the

stitch

length is increased

by

Vfii".

The stitch length is indicated on the teeth in millimeters.

Fig. 6 R8607

Loading...

Loading...