4. Winding the Bobbin

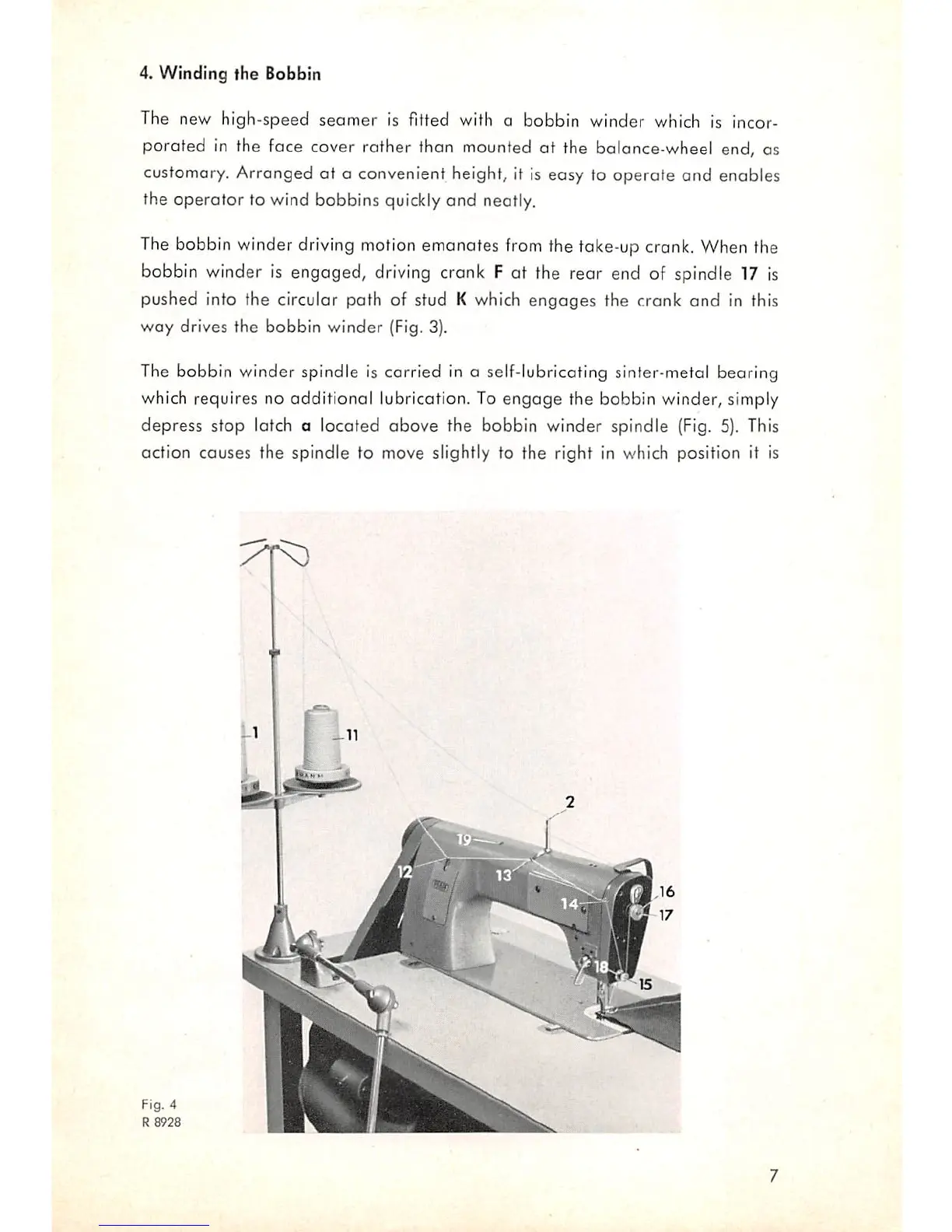

The new high-speed seamer is fitted with a bobbin winder which is incor

porated in the face cover rother than mounted at the balance-wheel end, as

customary. Arranged at a convenient height, it is easy to operate end enables

the operator to wind bobbins

quickly

and neatly.

The bobbin winder driving

motion

emanates from the take-up crank. When the

bobbin winder is engaged, driving crank F at the rear end of spindle 17 is

pushed into the circular path of stud K which engages the crank and in this

way drives the bobbin winder (Fig. 3).

The bobbin winder spindle is carried in a self-lubricating sinter-metal bearing

which requires no additional lubrication. To

engage

the bobbin winder, simply

depress stop latch a located above the bobbin winder spindle (Fig. 5). This

action causes the spindle to move slightly to the right in which position it is

Fig. 4

R

8928

Loading...

Loading...