17

1063_0_Product_Manual - October 27, 2010 2:54 PM

Disabling the PhidgetStepperBipolar

When the stepper motor has rotated the requested number of steps, and is stopped, the coils will remain energized

to hold it in position. This is necessary to allow the motor to support a load on its shaft without rotating to an

unknown position.

The amount of current required to hold a motor shaft in place is called the holding current, and is based mainly on

the resistance of the motor coils and the load being supported by the motor. The current required to produce the

holding torque can often be large enough to cause the motor to generate heat from the power dissipated in the

coils.Ifthemotorisnotsupportingaloadorisnotrequiredtomaintainaspecicangle,itisrecommendedto

set the Enable property to false. This will allow the motor shaft to rotate freely, but the present angle may be lost

iforces on the motor-shaft are greater than can be resisted by the detent torque of the unpowered motor.

It is also possible to reduce the CurrentLimit in software, to retain some holding torque while consuming less power.

Starting the motor

Whenthesteppersarerstengagedfromsoftware,thesteppermotorlikelywillnotbeatthesamestateasthe

default output state of the controller. This will cause the stepper to ‘snap’ to the position asserted by the controller -

potentially moving by 2 full steps.

High Precision Applications

Stepper motor precision is limited by the manufacturing process used to build them. Errors in the rotor and coils will

cause some degree of inaccuracy. In our experience, inexpensive stepper motors will often have positioning errors

approaching a half-step.

Synchronization of multiple motors

Many applications call for several steppers motors operating in unison - for example, operating a CNC table, or a

robot arm. Highly precise synchronization of steppers using the PhidgetStepper is not possible, as the sequencing

will be affected by the real-time performance of your operating system. Each stepper is controlled as a independent

unit, so there is no way of arranging for a particular action to happen to all motors at the same time. Typical jitter

can be 10-30mS.

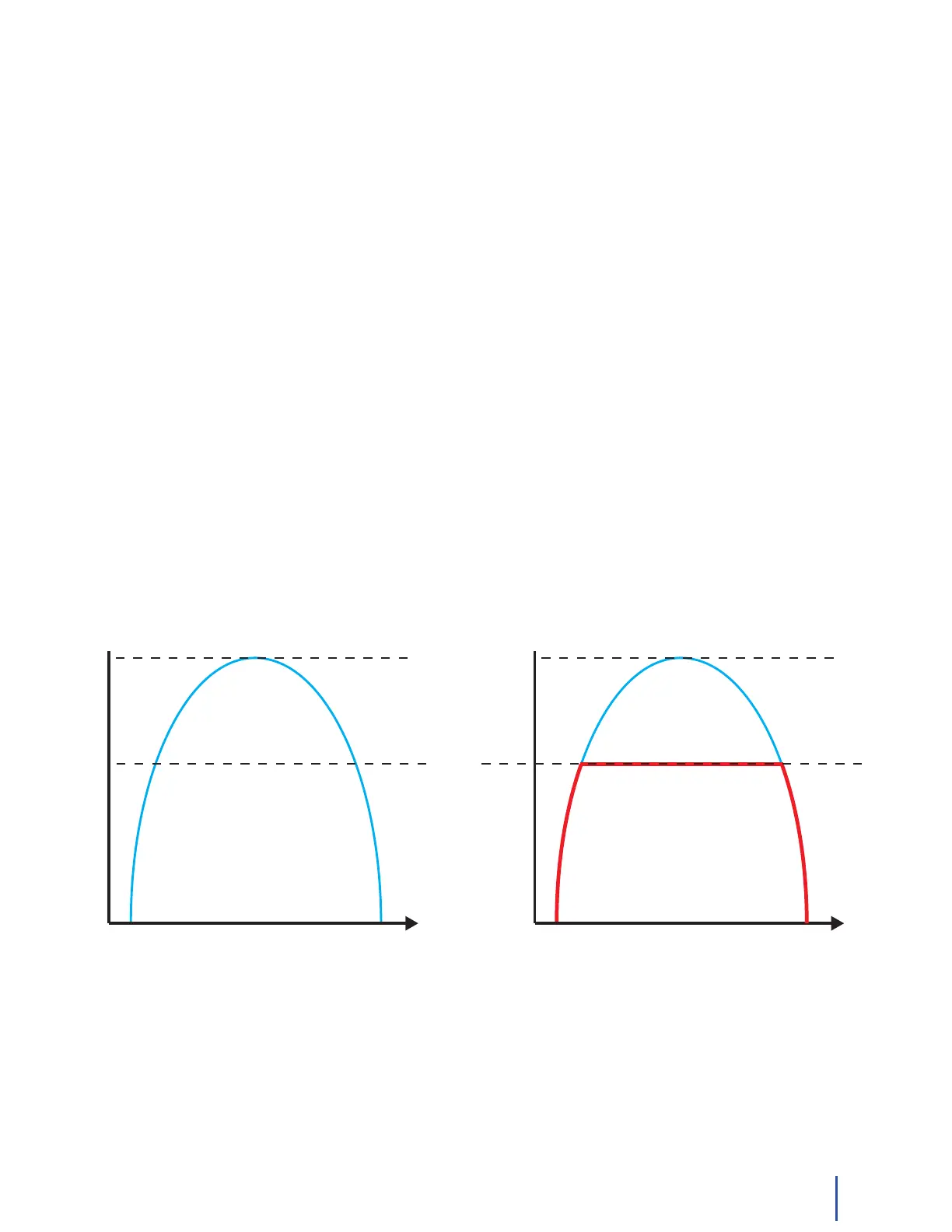

time

100%

DC current (Amps)

2.5A

0A

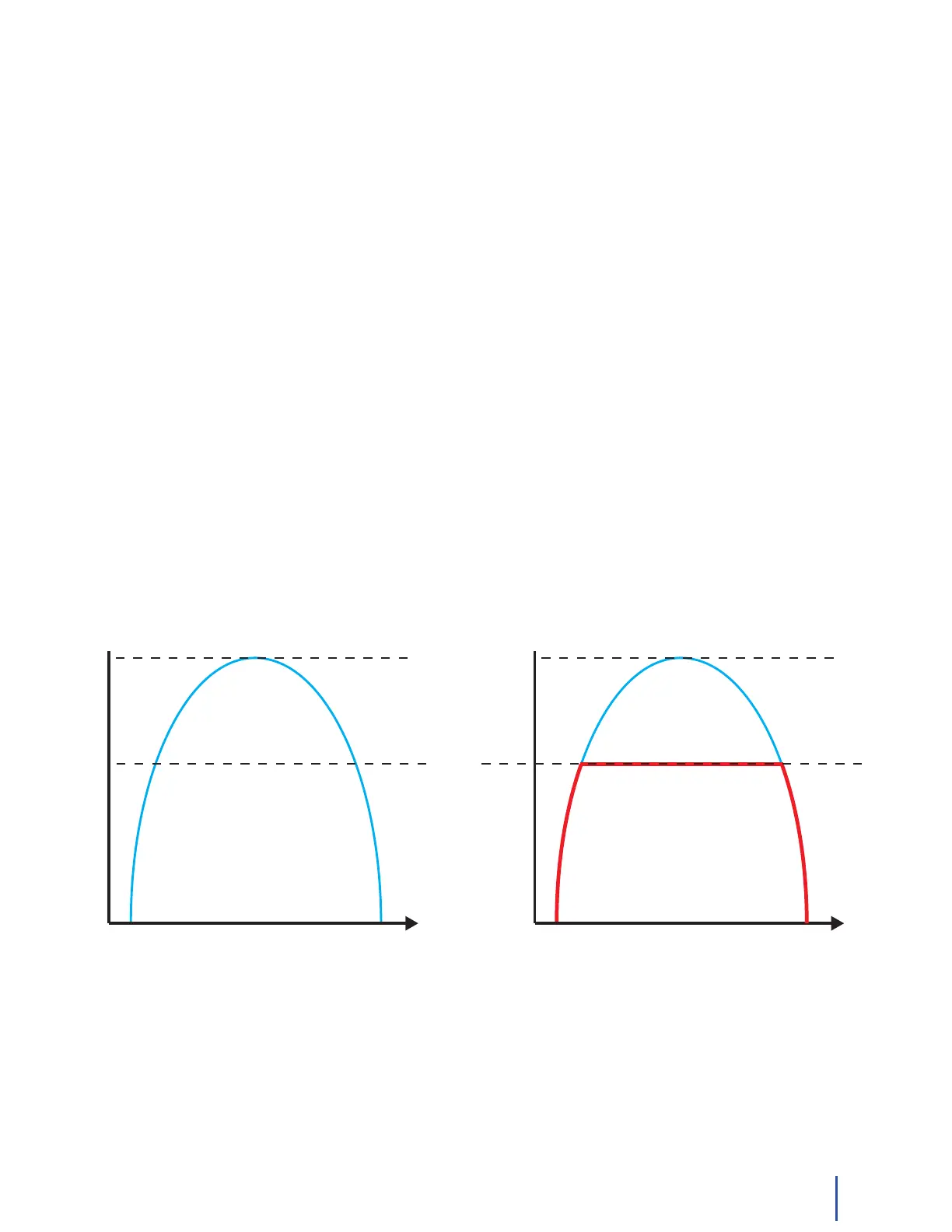

time

100%

2.5A

0A

current limit

of coil

d

e

n

e

d

c

u

r

r

e

n

t

l

i

m

i

t

r

e

s

u

l

t

i

n

g

c

o

i

l

c

u

r

r

e

n

t

Loading...

Loading...