RAD-...-IFS

156 / 198

PHOENIX CONTACT 105542_en_05

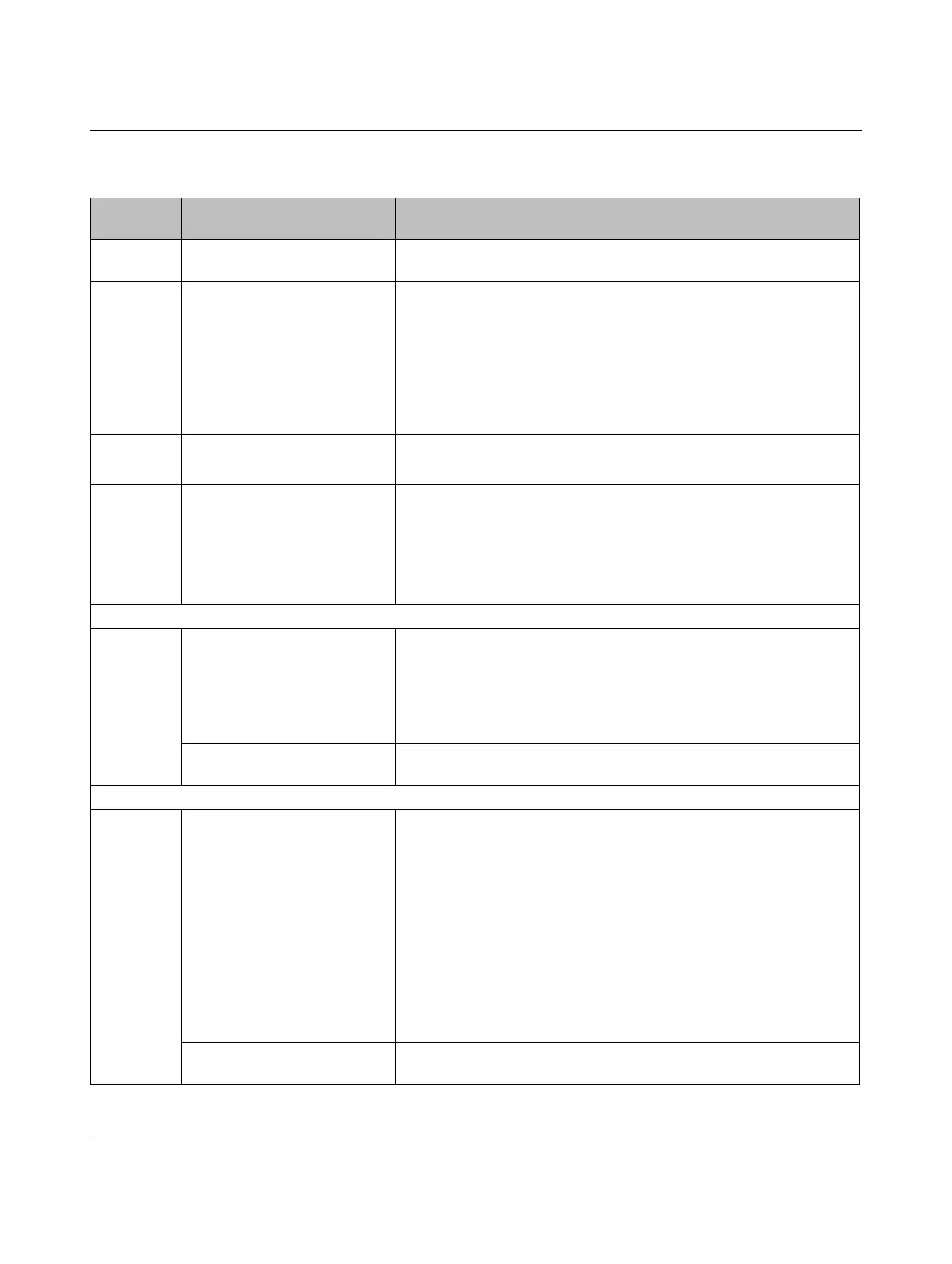

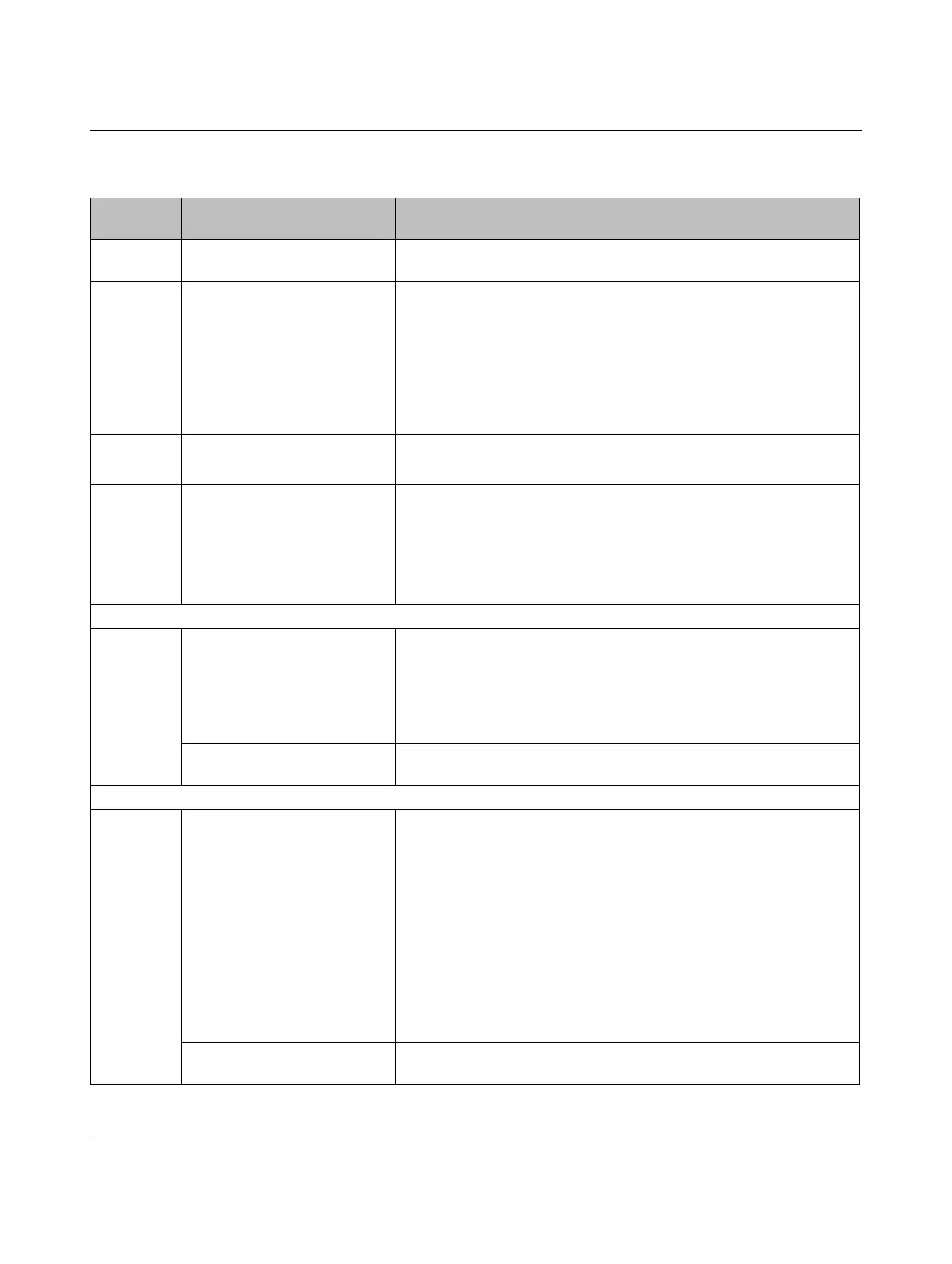

Table 9-2 Detecting and removing errors: I/O extension module

LED,

I/O module

Current state and possible

cause

Solution

PWR off

No power supply, mains proba-

bly switched off

• Switch on the mains, restore the power supply.

DAT off

No communication between

wireless module and

I/O extension module. The wire-

less module is probably in “serial

data” mode.

• Check whether the I/O extension module is properly snapped onto

the DIN rail connector and whether it is connected to the wireless

module.

• Check the operating mode of the wireless module using the

PSI-CONF software. The wireless module must be in “I/O data”,

“PLC / Modbus/RTU” mode or in dual mode (see page 38).

• Reset the wireless module to the default settings (I/O data mode,

see page 30), if necessary.

ERR on

Critical internal error

Example: technical defect

• Please contact Phoenix Contact technical support.

ERR flash-

ing slowly

(1.4 Hz)

I/O MAP address changed

Example: the white thumbwheel

setting has accidentally been

modified and the modification

has not yet been confirmed via

the SET button.

• Check the I/O MAP address setting on the white thumbwheel of the

I/O extension module.

• If necessary, set the correct I/O MAP address and press the SET

button on the wireless module.

In I/O data mode

ERR flash-

ing fast

(2.8 Hz)

Missing input module

Example: an output module is

not assigned the corresponding

input module with the same

I/O MAP address.

• Check whether an input module with the same I/O MAP address has

been assigned to every output module.

• Use the white thumbwheel on the extension module to set the

I/O MAP address (01 ... 99). The input module must be provided with

the same I/O MAP address as the assigned output module at anoth-

er station.

No bus communication,

no wireless connection present

• See measures for the wireless module, page 153

In PLC / Modbus/RTU mode

ERR flash-

ing fast

(2.8 Hz)

No Modbus communication

(safe state of outputs, depend-

ing on DIP switch settings)

• Check the communication line between the Modbus/RTU controller

and the master wireless module using RAD ID 01.

• Check the wiring of the RS-232/RS-485 connections on the master

and the PLC.

• Check the serial interface settings (baud rate, parity, data bits, and

stop bits) on the master and the PLC (from page 38 onwards).

• Check whether the I/O extension module is properly snapped onto

the DIN rail connector.

• Use the PSI-CONF software to check if the wireless module is in

“PLC / Modbus/RTU” mode or in dual mode (see page 38).

• Press the SET button on the wireless module or carry out a power up

in order to read the station structure.

No bus communication,

no wireless connection present

• See measures for the wireless module, page 153

Loading...

Loading...