ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian)

I.2.1 DISPLAY OF CURRENT CALIBRATION FACTOR

AND RESTORING FACTORY FACTOR.

CALCAL

CAL

By pressing the CAL key while the appli-

ance is in Standby, the display page ap-

pears showing the current calibration fac-

tor used. If no calibration has ever been

performed, or the factory seing has been

restored aer previous calibrations, the

following display page will appear:

The word “Fact” abbreviation for “factory”

shows that the factory calibration factor is

being used

If, on the other hand, calibrations have

been made by the user, the display page

will appear showing the currently used

calibration factor ( in our example 0,998) .

The word “user” indicates a calibration fac-

tor set by the user is being used..

CAL

The flow chart alongside

shows the switchover logic

from one display page to

another

In this condition, the Reset

key permits switching from

User factor to Factory fac-

to r.

To confirm the choice of

calibration factor, quickly

press CAL while “User” or

“Fact” are displayed.

Aer the restart cycle, the

K24 uses the calibration

factor that has just been

confirmed

CAL

CALCAL

CAL

RESET

RESET

TIME OUT

NOTICE

When the Factory Factor is confirmed, the old User

factor is deleted from the memory

I.2.2 IN FIELD CALIBRATION

FOREWORD

This procedure calls for the fluid to be dispensed into a graduated

sample container in real operating conditions ( flow rate, viscosity,

etc.) requiring maximum precision.

NOTICE

For correct K24 calibration, it is most important to:

1

When the Factory Factor is confirmed, the old User factor is deleted

from the memory

2

use a precise Sample Container with a capacity of not less than 5

litres, featuring an accurate graduated indicator.

3

ensure calibration dispensing is done at a constant flow rate equiva-

lent to that of normal use, until the container is full;

4

Not reduce the flow rate to reach the graduated area of the con-

tainer during the final dispensing stage (the correct method during

the final stages of sample container filling consists in making short

top-ups at normal operation flow rate);

5

aer dispensing, wait a few minutes to make sure any air bubbles are

eliminated from the sample container; only read the Real value at the

end of this stage, during which the level in the container could drop.

6

Carefully follow the procedure indicated below.

I.2.2.1 IN-FIELD CALIBRATION PROCEDURE

ACTION DISPLAY

1

NONE

Meter in Standby

2

CALCAL

CAL

LONG CAL key keying

The Meter enters calibration mode, shows <<CAL>> and displays

the calibration factor in use instead of partial. The words “Fact” and

“USER” indicate which of the two factors (factory or user) is currently

in use.

Important: This factor is that which the instrument also uses for field

calibration measurement operations

3

RESET

RESET

RESET

LONG RESET key keying

The Meter shows “CAL” and the partial at zero. The Meter is ready to

perform in-field calibration.

4

DISPENSING INTO SAMPLE CONTAINER

Without pressing any key, start dispensing into the sample container

Dispensing can be interrupted and started again at will. Continue

dispensing until the level of the fluid in the sample container has

reached the graduated area. There is no need to reach a preset

quantity.

Indicated value Real value

5

RESET

SHORT RESET key keying

The Meter is informed that the calibration dispensing operation is

finished.

Make sure dispensing is correctly finished before performing this

operation. To calibrate the Meter, the value indicated by the partial

totaliser (example 9.800) must be forced to the real value marked

on the graduated sample container. In the boom le part of the

display an arrow appears (upwards and downwards), that shows the

direction (increase or decrease) of the value change displayed when

the following operations 6 or 7 are performed.

6

RESET

SHORT RESET key keying

The arrow changes direction. The operation can be repeated to

alternate the direction of the arrow.

7

CALCAL

CAL

CAL

SHORT/LONG CAL key keying

The indicated value changes in the direction indicated by the arrow

- one unit for every short CAL key keying

- continually if the CAL key is kept pressed. The speed increase rises

by keeping the key pressed. If the desired value is exceeded, repeat

the operations from point (6).

8

RESET

RESET

RESET

LONG RESET key keying

The Meter is informed that the calibration procedure is finished.

Before performing this operation, make sure the INDICATED value is

the same as the REAL value.

Indicated value Real value

The Meter calculates the new USER K FACTOR ; this calculation

could require a few seconds, depending on the correction to be made

ATTENTION: If this operation is performed aer action (5), without

changing the indicated value, the USER K FACTOR would be the

same as the FACTORY K FACTOR, thus it is ignored.

9

NO OPERATION

At the end of the calculation, the new USER K FACTOR is shown

for a few seconds, aer which the restart cycle is repeated to finally

achieve standby condition.

IMPORTANT: From now on, the indicated factor will become the

calibration factor used by the Meter and will continue to remain

such even aer a baery change

10

NO OPERATION

The Meter stores the new work calibration factor and is ready

to begin dispensing, using the USER K FACTOR that has just

been calculated.

.

I.2.3 DIRECT MODIFICATION OF K FACTOR

If normal Meter operation shows a mean percentage error, this can be corrected by

applying to the currently used calibration factor a correction of the same percent-

age. In this case, the percentage correction of the USER K FACTOR must be calcu-

lated by the operator in the following way

New cal. Factor = Old Cal Factor *

( )

100 - E%

100

Example:

Error percentage found: E% - 0.9 %

CURRENT calibration factor: 1.000

New USER K FACTOR: 1.000 * [(100 – ( - 0.9))/100] = 1.000 * [(100 + 0.9)/100] =

1.009

If the Meter indicates less than the real dispensed value (negative error) the new cali-

bration factor must be higher than the old one as shown in the example. The opposite

applies if the Meter shows more than the real dispensed value (positive error).

ACTION DISPLAY

1 NONE

METER in Standby.

2

CALCAL

CAL

LONG CAL KEY KEYING

Meter enters calibration mode, shows “CAL” and displays the

calibration factor being used instead of the partial. The words “Fact”

and “User” indicate which of the two factors (factory or user) is

currently being used.

3

RESET

RESET

RESET

LONG RESET KEY KEYING

The Meter shows “CAL” and the zero partial total.

Meter is ready to perform in-field calibration by dispensing – see

previous paragraph.

4

RESET

RESET

RESET

LONG RESET KEY KEYING

We now go on to Direct change of the calibration factor: the word

“Direct” appears together with the Currently Used calibration factor.

In the boom le part of the display, an arrow appears (upwards or

downwards) defining the direction (increase or decrease) of change

of the displayed value when subsequent operations 5 or 6 are

performed.

5

RESET

SHORT RESET KEY KEYING

Changes the direction of the arrow. The operation can be repeated to

alternate the direction of the arrow.

6

CALCAL

CAL

CAL

SHORT/LONG CAL KEY KEYING

The indicated value changes in the direction indicated by the arrow

- one unit for every short CAL key keying

- continually if the CAL key is kept pressed. The speed increase rises

by keeping the key pressed. If the desired value is exceeded, repeat

the operations from point (5).

7

RESET

RESET

RESET

LONG RESET KEY KEYING

The Meter is informed that the calibration procedure is finished.

Before performing this operation, make sure the INDICATED value

is that required.

8 NO OPERATION

At the end of the calculation, the new USER K FACTOR is shown

for a few seconds, aer which the restart cycle is repeated to finally

achieve standby condition.

IMPORTANT: From now on, the indicated factor will become the

calibration factor used by the Meter and will continue to remain

such even aer a baery change

9 NO OPERATION

The Meter stores the new work calibration factor and is ready to

begin dispensing, using the USER K FACTOR that has just been

changed.

L METER CONFIGURATION

The METER feature a menu with which the user can select the main measurement

unit, Quarts (Qts), Pints (Pts), Litres (Lit), Gallons (Gal); The combination of the

unit of measurement of the Partial register and that of the Totals is predefined

according to the following table:

Combination no.

Unit of Measurement

Partial Register

Unit of Measurement

Totals Register

1 Litres (L) Litres (L)

2 Gallons (Gal) Gallons (Gal)

3 Quarts (Qts) Gallons (Gal)

4 Pints (Pts) Gallons (Gal)

To choose between the 4 available combinations:

1 Wait for the METER to go to Standby

2

CAL

RESET

+

Then press the CAL and RESET keys together. Keep these

pressed until the word “UNIT” appears on the screen to-

gether with the unit of measurement set at that time (in

this example Litres / Litres )

3 Every short press of the RESET key, the various combina-

tions of the units of measurements are scrolled as shown

below:

Gal

Qts

Pts

Gal

RESET

RESET

RESET

4

CALCAL

CAL

By pressing the CAL key at length, the new seings will be

stored, the METER will pass through the start cycle and

will then be ready to dispense in the set units.

NOTICE

The Reset Total and Total registers will be automati-

cally changed to the new unit of measurement.

NO new calibration is required aer changing the Unit of Mea-

surement.

M MAINTENANCE

BATTERY

REPLACEMENT

Use only Piusi Baery code *18021

WARNING

To reduce risk of ignition of a flammable or explosive

atmosphere do not use Volt meter or smiliar powered

tools during the live maintenance.

WARNING

The warranty and the safety of the product is insured

only with the use of baery Piusi code *18021 PIUSI

S.p.A. DENIES LIABILITY FOR DAMAGES CAUSED

BY THE USE OF BAT TERIES NOT SUITABLE.

K24 should be installed in a position allowing the bat-

teries to be replaced without removing it from the

system.

BATTERIES Check the baeries and terminals at least every year

to ensure proper operation. It is strongly recommend-

ed that terminals be cleaned annually

K24 features two low-baery alarm levels:

1

When the baery charge falls below the first level on the

LCD, the fixed baery symbol appears. In this condition,

K24 continues to operate correctly, but the fixed icon

warns the user that it is ADVISABLE to change the bat-

teries.

2

If K24 operation continues without changing the baer-

ies, the second baery alarm level will be reached which

will prevent operation. In this condition the baery icon

starts to flash and is the only one to remain visible on the

LCD.

WARNING

During meter removal, liquid may spill. Follow the liq-

uid manifacturer’s safety precautions for clean up of

minor spills.

TO REMOVE

BATTERY

1 Ensure all liquid is drained from the meter. This could

include draining the hose, meter, nozzle or pipe

2

Wear protective clothing as necessary, loosen both ends

of the meter. Use a wrench only on the meter’s flat metal

surfaces

3 If the meter is not immediately installed again, cap

the hose end or pipe to prevent spills

To reduce the risk of ignition of a flammable or explo-

sive atmosphere, baeries must only be changed in a

non-hazardous location

To prevent ignition of flammable or combustibile at-

mospheres, disconnect power before servicing

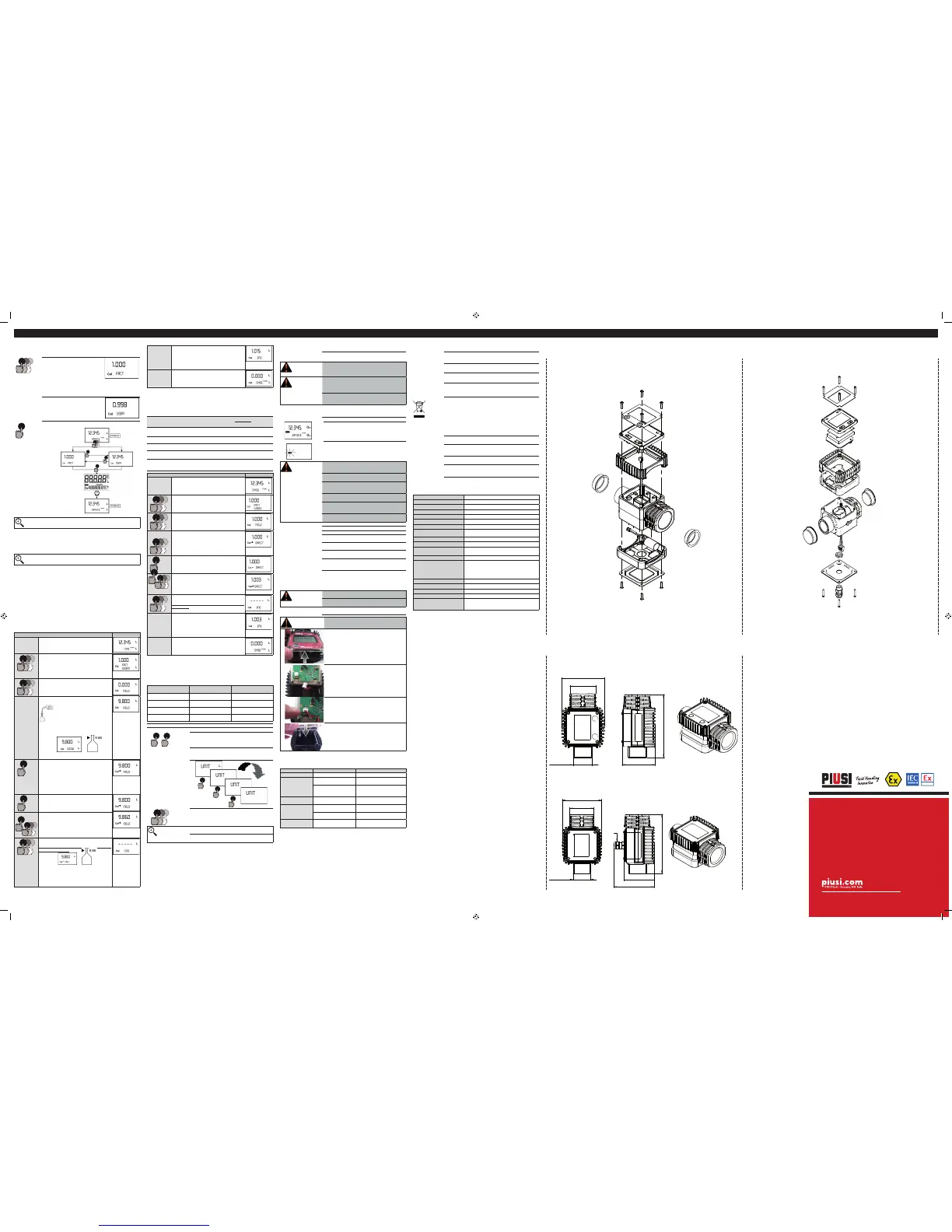

To change the

baeries, with

reference to

the exploded

diagram posi-

tions, proceed as

follows

1 Press RESET to update all the totals

2 Loosen the 4 fixing screws of the lower cover

3 Remove the old baeries and disconnect the plug

4

Place the new baeries in the same position as the old ones

(sure to put the baery in the correct way)

5 Close the cover again, by positioning the rubber protec-

tion as a gasket

6 K24 will switch on automatically and normal operation can

be resumed

The K24 will display the same Reset Total, the same Total and the same Partial

indicated before the baeries were changed. Aer changing the baeries, the

meter does not need calibrating again.

CLEANING

Only one operation is necessary to clean the k24. Aer

removing k24 from the plant where it was built in, any re-

sidual elements can be removed by washing or mechani-

cally-handling. If this operation does not restore a smooth

rotation of the turbine, it will have to be replaced.

WARNING

Do not discard the old baeries in the environment.

Refer to local disposal regulations.

Do not use compressed air onto the turbine in order to

avoid its damage because of an excessive rotation

TO STORE Follow the liquid manifacturer’s instructions for the

disposal of contaminated cleaning solvents

WARNING

K24 Front face replacement

1

Carefully remove the screws from the corners of the

front panel, and then carefully li the front cover up

away from the main body of the meter.

2

Carefully remove the screws from the corners of the

front panel, and then carefully li the front cover up

away from the main body of the meter.

3

When the new panel is fied make sure the power adapt-

er is fied correctly with the location pin in the correct

way

4

Carefully refit the display panel back onto the main

body making sure the wire is tucked into the corner

and replace the screws

N MALFUNCTIONS (EN60079-19)

Problem Possible cause Remedial Action

LCD: no indication

Bad baery contact Check baery contacts

Not enough mea-

surement precision

Wrong K FACTOR

With reference to paragraph H,

check the K FACTOR

The meter works below

minimum acceptable flow

rate.

Increase the flow rate until an ac-

ceptable flow rate range has been

achieved

Reduced or zero

flow rate

TURBINE blocked Clean the TURBINE

The meter does not

count, but the flow

rate is correct

Incorrect installation of

gears aer cleaning

Repeat the reassembly procedure

Possible electronic card prob-

lems

Contact your dealer

K24 is switched of

Baery discharged or in-

stalled in the wrong way

Check baery charge and/or

check the baery position

O DISPOSAL

Foreword

If the system needs to be disposed, the parts which make it up

must be delivered to companies that specialize in the recycling

and disposal of industrial waste and, in particular:

Disposing of

packing materials

The packaging consists of biodegradable cardboard which can be

delivered to companies for normal recycling of cellulose.

Metal Parts Dis-

posal

Metal parts, whether paint-finished or in stainless steel, can be

consigned to scrap metal collectors.

Disposal of elec-

tric and electron-

ic components

These must be disposed of by companies that specialize in the

disposal of electronic components, in accordance with the indica-

tions of directive 2012/19/CE (see text of directive below).

Informa-

tion re-

garding

the envi-

ronment

for clients resid-

ing within the Eu-

ropean Union

European Directive 2012/19/EC requires that all equipment

marked with this symbol on the product and/or packaging not

be disposed of together with non-differentiated urban waste.

The symbol indicates that this product must not be disposed of

together with normal household waste. It is the responsibility of

the owner to dispose of these products as well as other electric

or electronic equipment by means of the specific refuse collec-

tion structures indicated by the government or the local governing

authorities.

Disposing of RAEE equipment as household wastes is strictly for-

bidden. Such wastes must be disposed of separately.

Any hazardous substances in the electrical and electronic appli-

ances and/or the misuse of such appliances can have potentially

serious consequences for the environment and human health.

In case of the unlawful disposal of said wastes, fines will be ap-

plicable as defined by the laws in force.

Miscellaneous

parts disposal

Other components, such as pipes, rubber gaskets, plastic parts

and wires, must be disposed of by companies specialising in the

disposal of industrial waste.

P TECHNICAL DATA

Measurement system

TURBINE

Resolution (nominal)

0.010 lit/pulse 0.006 gall./pulse

Flow Rate (Range)

7 ÷ 120 (Lit/min) 2 ÷ 32 (gal/min)

Operating pressure (Max)

20 (Bar) 290 (psi)

Bursting pressure (Min)

100 (Bar) 1450 (psi)

Storage temperature (Range)

-20 ÷ + 70 (°C) -4 ÷ 158 (°F)

Storage humidity (Max)

95 (% RU)

Operating temperature

(Range)

-10 ÷ + 50 (°C) 14 ÷ 122 (°F)

Flow resistance

0.30 Bar at 100 lit/min. 4.35 psi a 26.41gal/min

Permissible Viscosity (Range)

2 ÷ 5.35 cSt/ pulse

Accuracy

1% aer calibration within

10÷90 (litres/min) 2,65÷23,8 (gallons/min) range

Reproducibility (Typical)

0,3 (%)

Screen

Liquid crystals LCD. Featuring:

- 5-figure partial

- 6-figure Reset Total plus x10 / x100

6-figure non reset Total plus x10 / x100

Power Supply

Lithium baery PIUSI code *18021

Baery life

24 months

Weight

0.4 Kg (included baeries)

Protection

IP65

Pulser Data

Ui = 12 V

Ii = 100 mA

Pi = 0.3 W

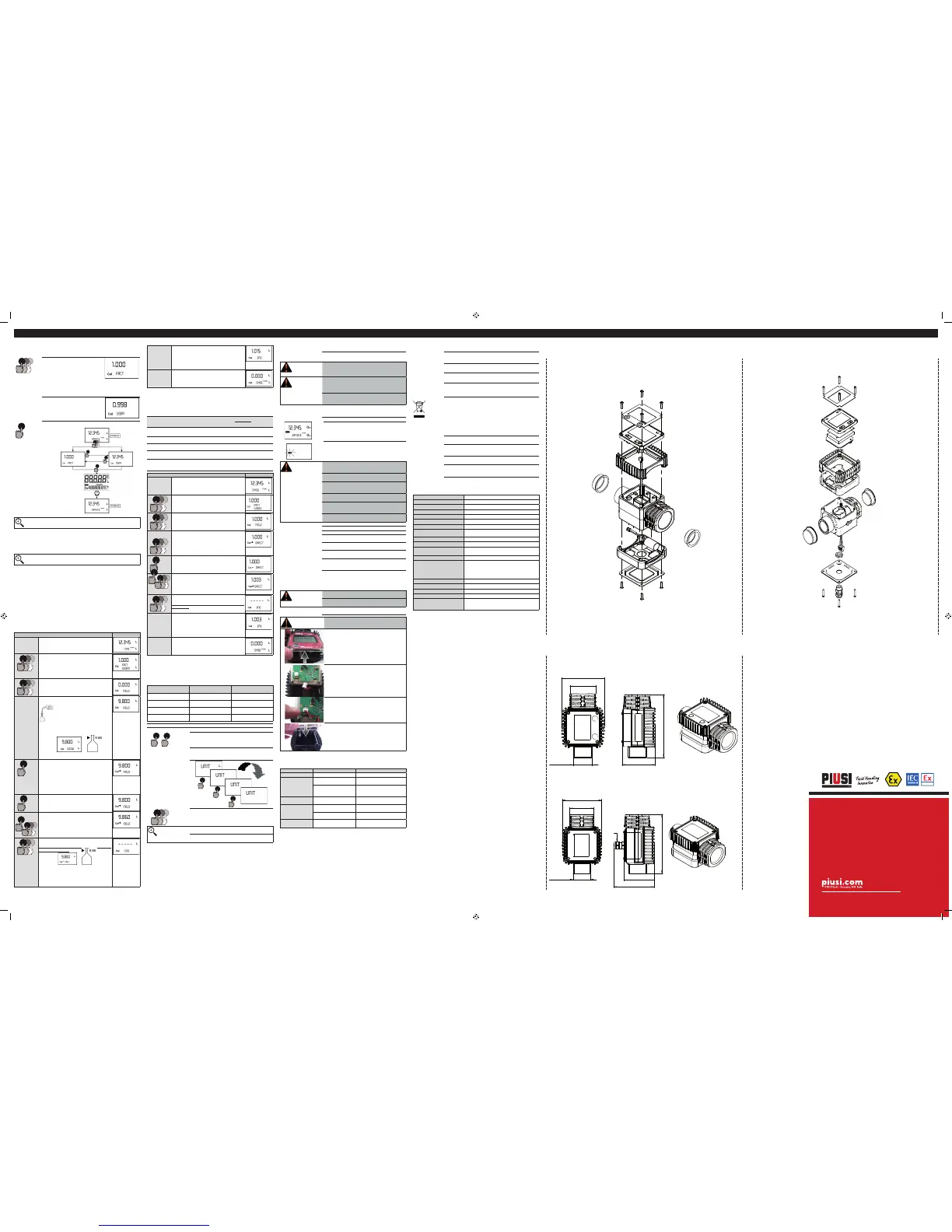

Q EXPLODED VIEWS AND OVERALL DIMENSIONS

METER PULSER

METER

46

1" NPT / BSP

113

76

59

PULSER

PG7

77

113

46

76

59

1" NPT / BSP

BULLETIN M0320 A EN _ 00

©Piusi S.p.A.

EN. This document has been drawn upwith the greatest

aention to precision and accuracy of all data herein contained.

Nevertheless, PIUSI S.p.A. denies liability for any possible

mistake or omission.

II 2 G

Atex

CES

13.0021X

Loading...

Loading...