12

To allow the tool to run without continually pressing the trigger (C), Fig. 8,

press the trigger (C) into the handle and engage the switch locking button (D)

on the side of the handle. While holding the button in, slowly release the

trigger. To stop the tool, squeeze trigger into handle and release.

To avoid personal injury or damage to finished work always

allow motor to come to a COMPLETE STOP before putting it down.

USING THE ROUTER

IMPORTANT: Before using the tool, consider the workpiece. Depending on

the material, more than one cut may be necessary to avoid overloading the

motor. Before beginning the cut on the actual workpiece, make a sample cut

on a piece of scrap lumber. This action will show exactly how the cut will look,

and will enable you to check dimensions.

Always secure the work to a stable surface prior to routing.

Generally, the workpiece should be secured to the bench by clamps. When

routing edges, the router should be held firmly down and against the work by

both guiding knobs.

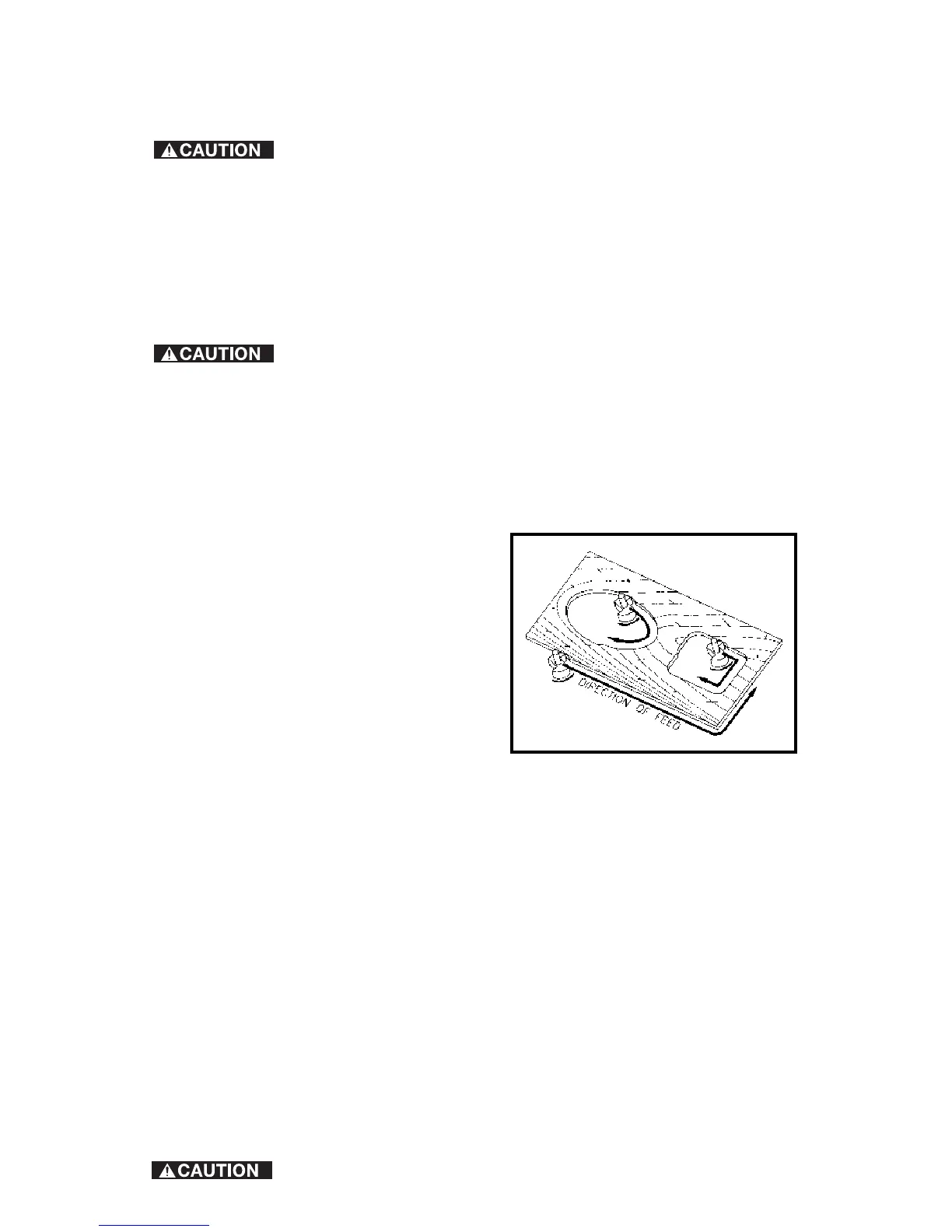

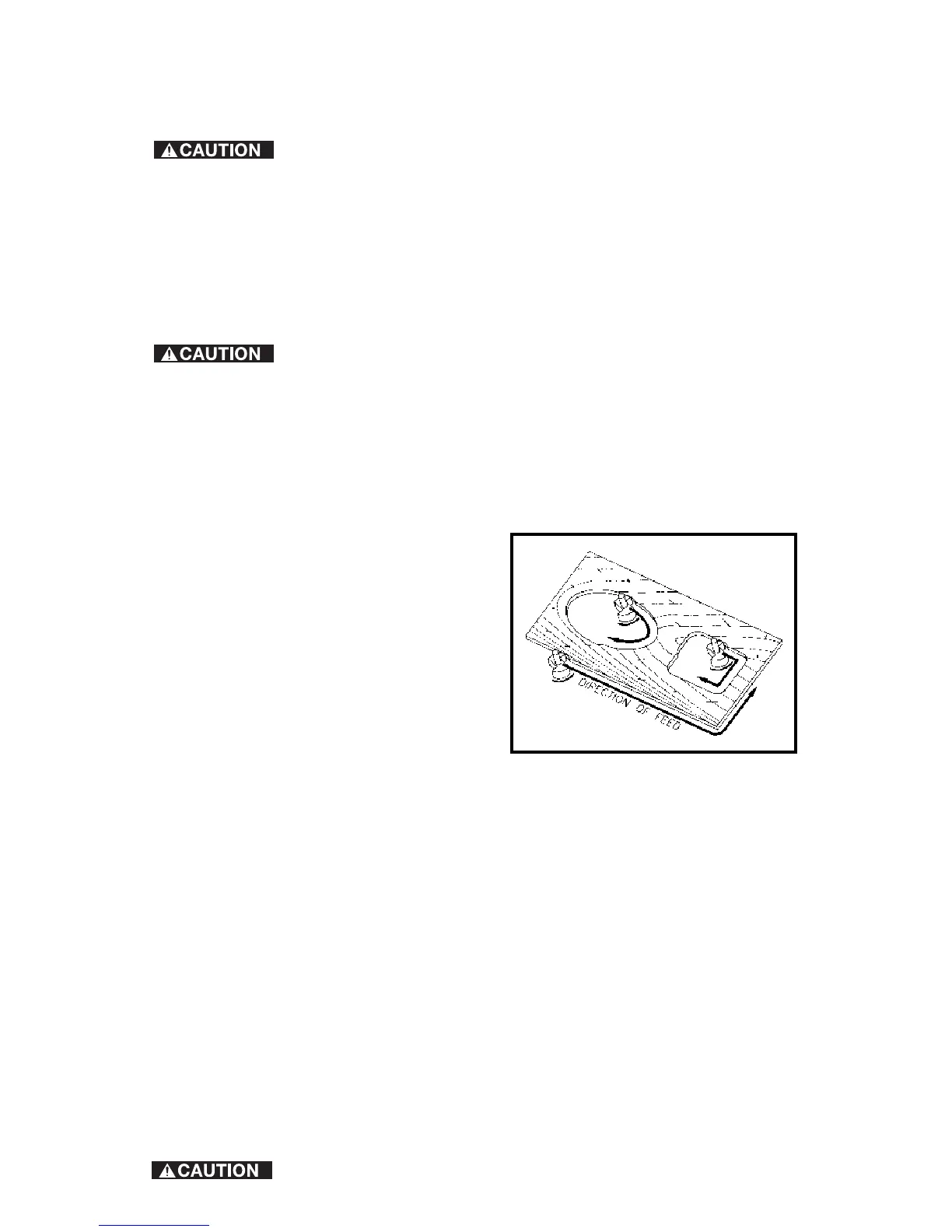

Since the cutter rotates clockwise (when viewing router from top), move the

router from left to right to obtain a more efficient cutting. (Fig. 9).

When working on the inside of a templet, move the router in clockwise

direction. When working on the outside of a templet, move the router in a

counter-clockwise direction.

WARNING: Avoid “Climb-Cutting”

(cutting in direction opposite that

shown in Fig. 9). “Climb-Cutting”

increases the chance for loss of control

resulting in possible personal injury.

When “Climb-Cutting” is required

(backing around a corner), exercise

extreme caution to maintain control of

the router.

The speed and depth of cut will depend

largely on the type of work material.

Keep the cutting pressure constant, but do not use so much pressure that the

motor speed slows excessively. More than one pass at various settings may

be necessary.

When making cuts on all four edges of the workpiece, start the first cut on the

end of the piece across the grain to minimize chipping of the wood at the end

of a cut.

THE EDGE GUIDE

An edge guide is available as an accessory to aid in straight edge planing,

parallel grooving, dado or slotting operations.

To attach, insert the guide rods (A) Fig. 10 in holes in the base, and secure it

with screws (B). The guide (C) is adjusted on the rods and secured in position

with thumb screws (D).

TEMPLET GUIDES

A wide variety of templet guides are available for use in pattern and templet

routing operations. Fig. 11 shows a typical combination bit, templet guide, and

locknut.

DISCONNECT TOOL FROM POWER SOURCE.

Fig. 9

Loading...

Loading...