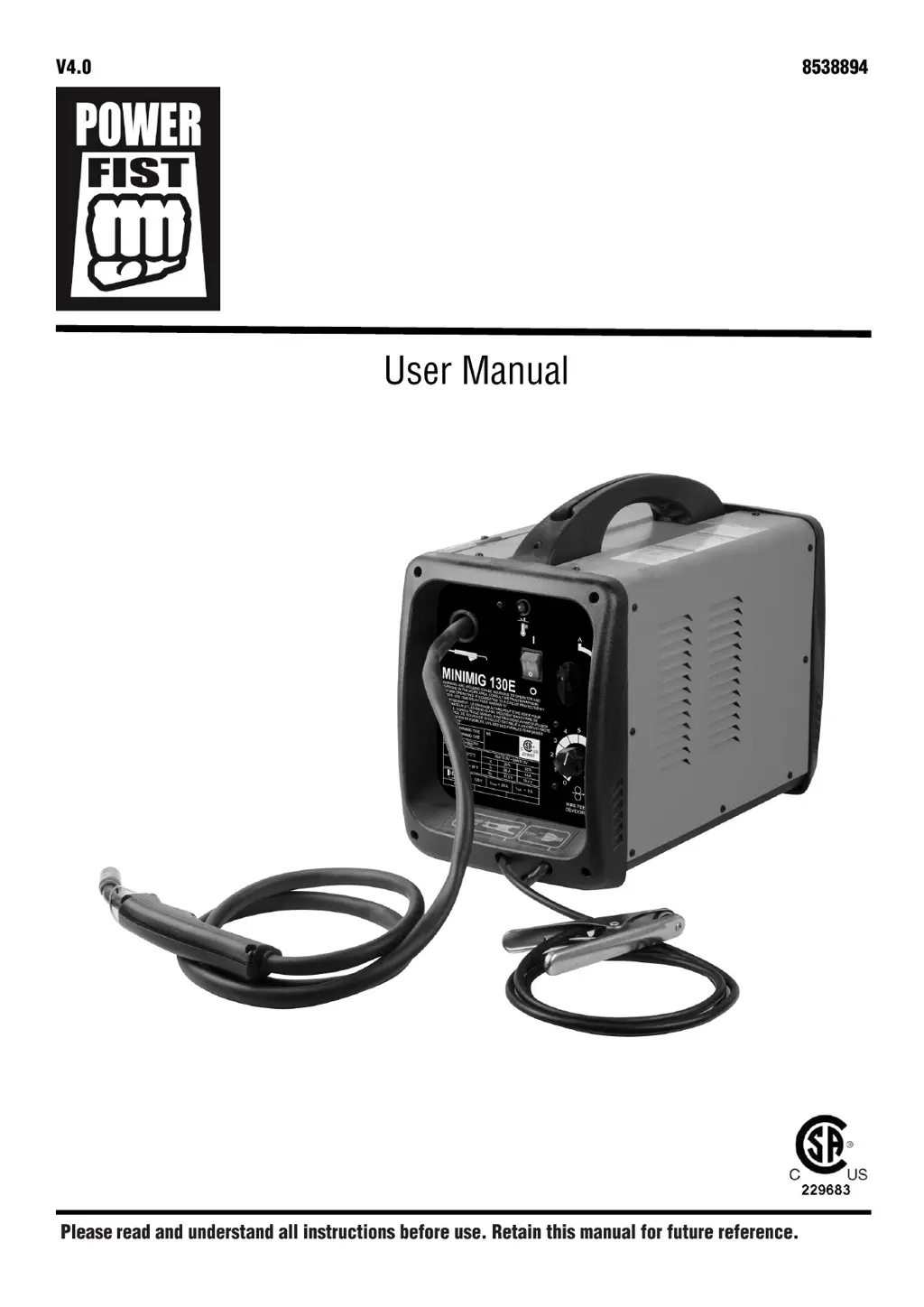

Why does my Power Fist MINIMIG 130E overheat and trip the circuit breaker?

- BburtonryanAug 4, 2025

Your Power Fist Welding System might be overheating due to the use of an extension cord or an overloaded circuit. If you're using an extension cord, try relocating the welding unit to avoid it, or use a thicker one. The welding unit requires a dedicated circuit, so remove all other electrical devices from the circuit.