Note:

All Pulleys in this step are 4 1/4” diameter, except where noted in step 8c.

Leave all pulley bolts hand tight until step 10 is completed.

A. See Diagram 1. Route Cable (90) through the top of the Upper Floating Pulley Bracket (V).

Install Pulley (A7) as shown in Diagram 2 using:

One 54 (3/8” x 2” hex head bolt)

Two 60 (3/8” washer)

One 70 (3/8” nylon lock nut)

B. See Diagram 1. Route Cable (90) up through the opening in Upper Main Frame (D).

Install Pulley (A8) under Cable (90) as shown using in Diagram 2:

One 52 (3/8” x 3 3/4” hex head bolt)

Two 14 (pulley spacer)

One 70 (3/8” nylon lock nut)

C. See Diagram 1. Route Cable (90) through the pulley bracket in Upper Main Frame (D).

Install 3 1/2” diameter Pulley (A9) as shown using in Diagram 2:

One 53 (3/8” x 1 1/2” hex head bolt)

Two 60 (3/8” washer)

One 70 (3/8” nylon lock nut)

D. See Diagram 1. Route Cable (90) through the pulley bracket in Rear Upper Beam (E) and then

down through the opening in Rear Upper Beam (E), and down toward weight stack.

Install Pulley (A10) under Cable (90) as shown using in Diagram 2:

One 53 (3/8” x 1 1/2” hex head bolt)

Two 60 (3/8” washer)

One 70 (3/8” nylon lock nut)

E. See Diagram 1A. The Metal Ball End of Cable (90) should be hanging just above the weight

stack. Remove Bolt (59) from Selector Rod Top Bolt (34), slide Metal Ball End of Cable (90)

through Selector Rod Top Bolt (34). Attach Cable End Shaft (33) and securely tighten

Allen Screw (8). Pull Cable (90) tight, so Cable End Shaft (33) fits securely inside Selector Rod

Top Bolt (34). Reinstall Bolt (59) in Selector Rod Top Bolt (34).

NOTE:

Make sure the Selector Rod Top Bolt (34) is threaded inside Selector Rod (31) at least

one half inch. Make sure Spring Lock Washer (63) is in place and wrench tighten Jam

Nut (71).

Be careful to assemble all components in the

sequence they are presented.

S T E P

8

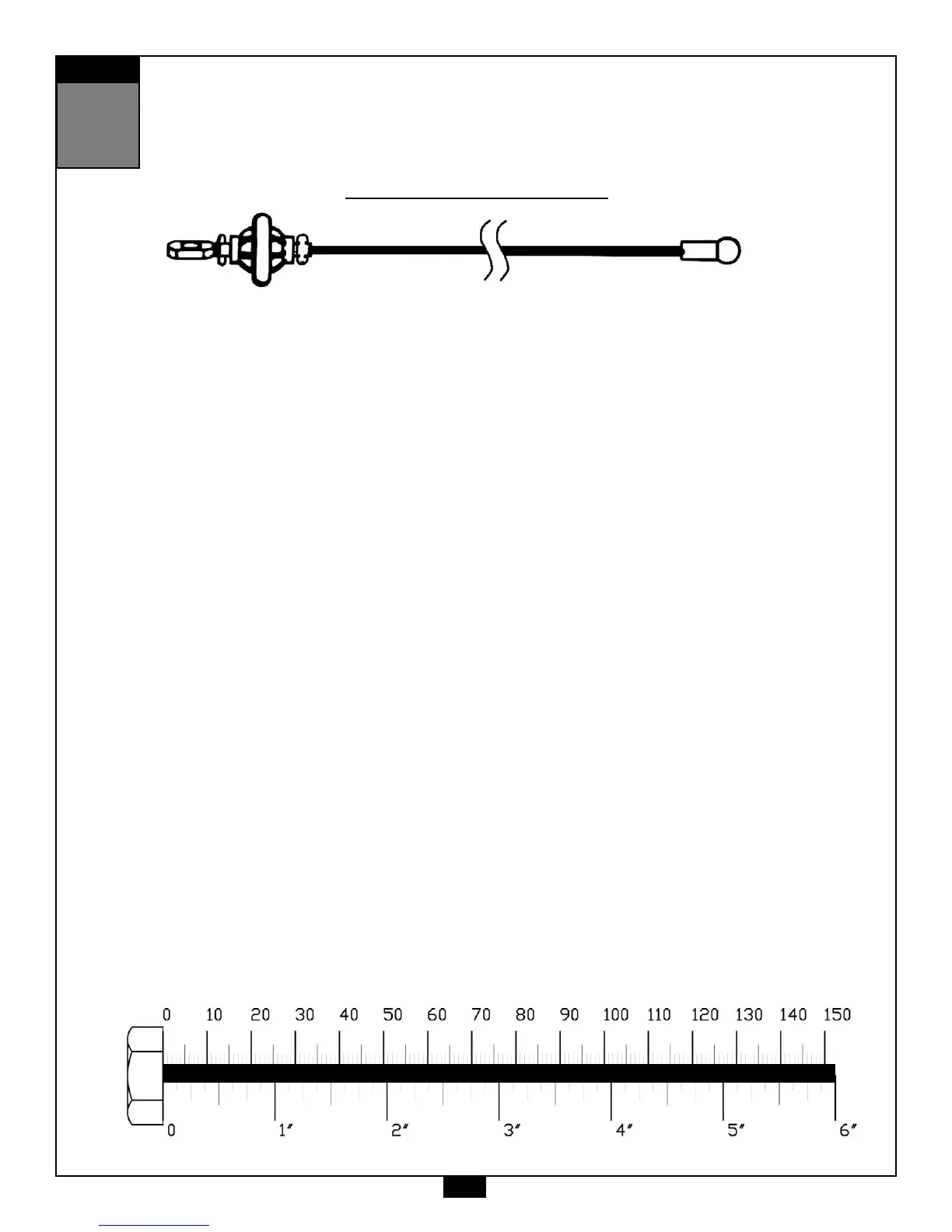

Inch

MM

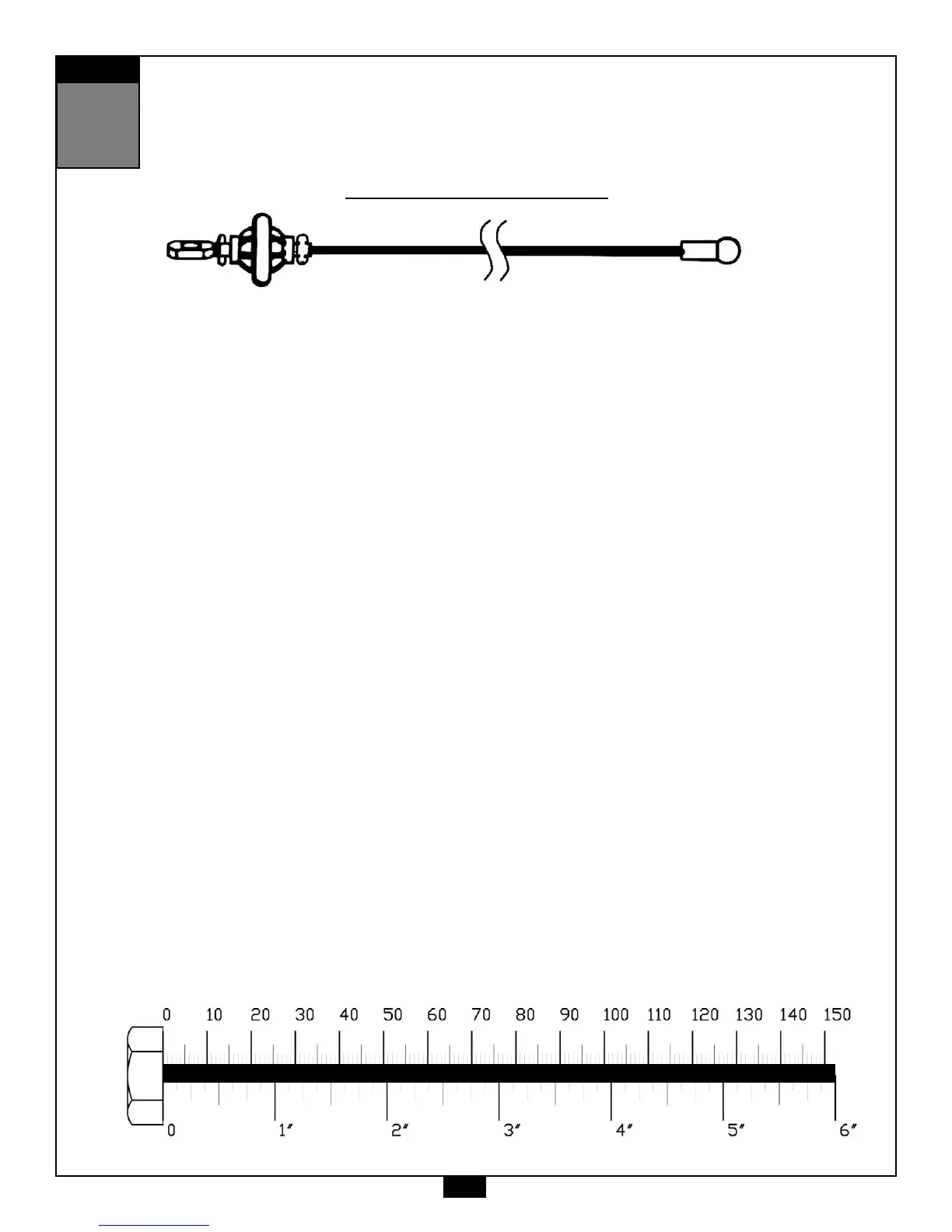

High Pulley Cable (90)

Ball Stop End

Metal Ball End

22

Loading...

Loading...